1. Overview of the Bottled Water Production Process

The production of bottled water involves four core stages:

- Water Sourcing and Treatment

- Bottle Manufacturing (Blow Molding)

- Filling and Capping

- Packaging and Labeling

Each stage relies on specialized machinery and stringent quality controls to ensure compliance with health standards and operational efficiency. Below, we break down these steps and highlight cutting-edge technologies that set modern production lines apart.

2. Water Treatment Equipment: Ensuring Purity and Safety

The foundation of any bottled water brand is the quality of its water. Whether sourced from natural springs, wells, or municipal supplies, raw water must undergo rigorous treatment to meet regulatory and consumer standards.

Key Water Treatment Steps

- Filtration: Multi-stage filters remove sediments, chlorine, and organic contaminants.

- Reverse Osmosis (RO): Removes dissolved salts, heavy metals, and microorganisms.

- UV Sterilization: Destroys bacteria and viruses without chemicals.

- Ozonation: Adds ozone gas to disinfect water and extend shelf life.

- Mineralization (Optional): Reintroduces minerals like calcium and magnesium for taste and health benefits.

Recommended Equipment:

- Reverse Osmosis Systems (e.g., Dow Filmtec membranes)

- UV Light Sterilizers (e.g., TrojanUV systems)

- Ozone Generators (e.g., Ozotech models)

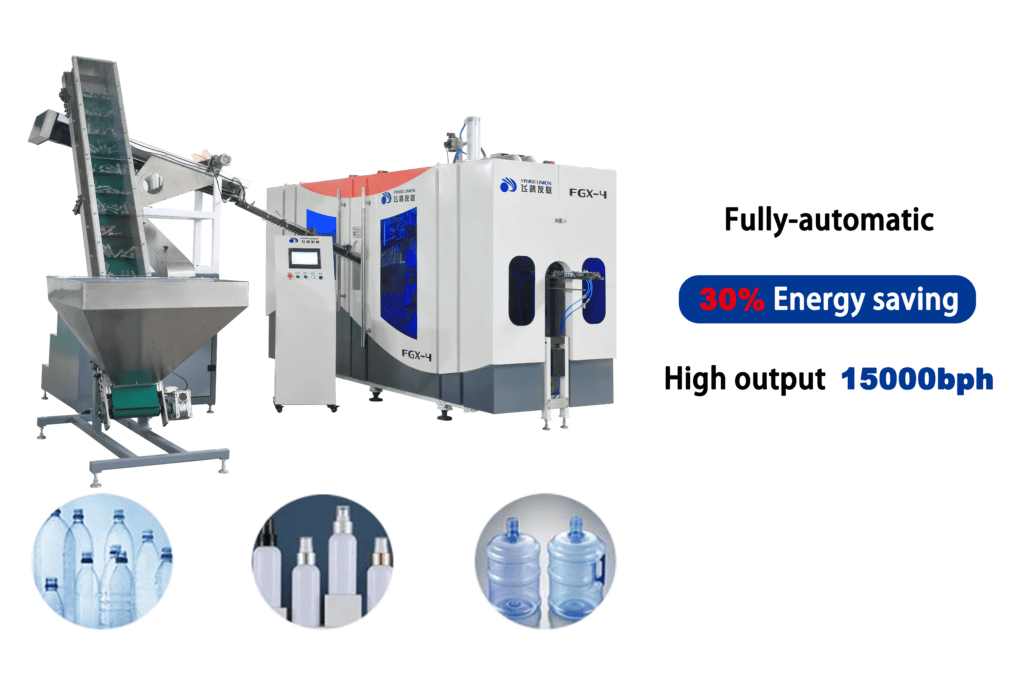

3. Bottle Manufacturing Equipment: Blow Molding Machines

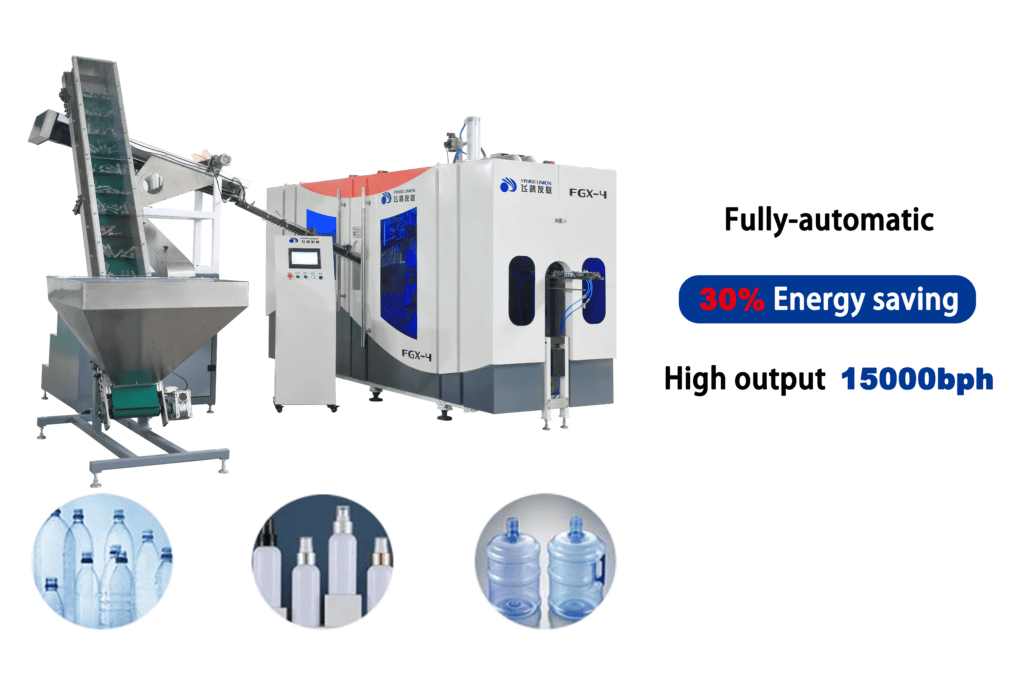

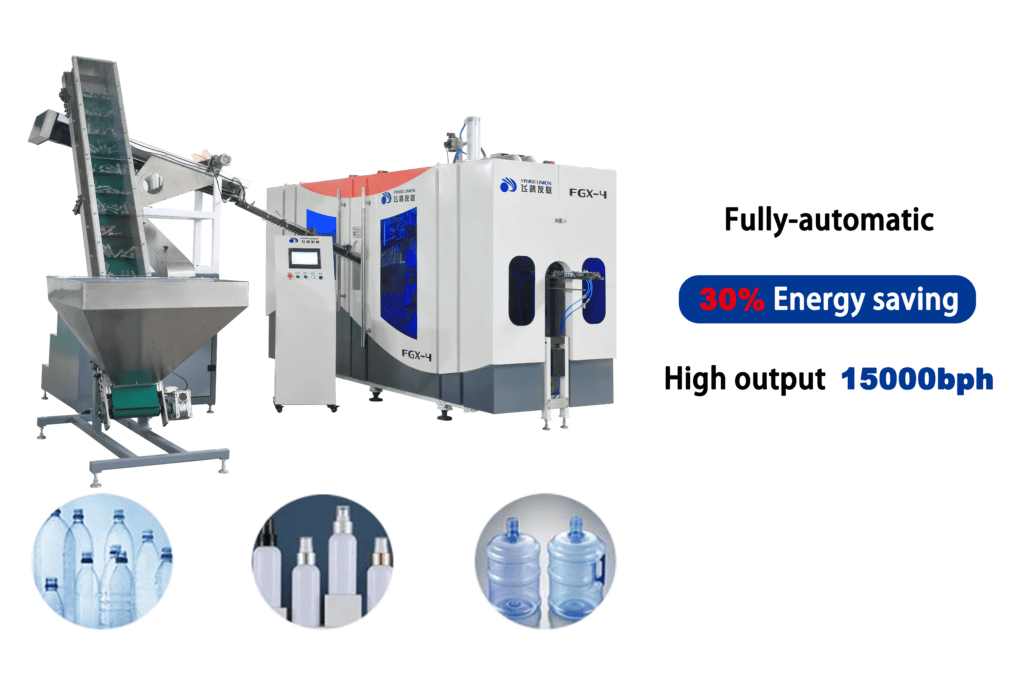

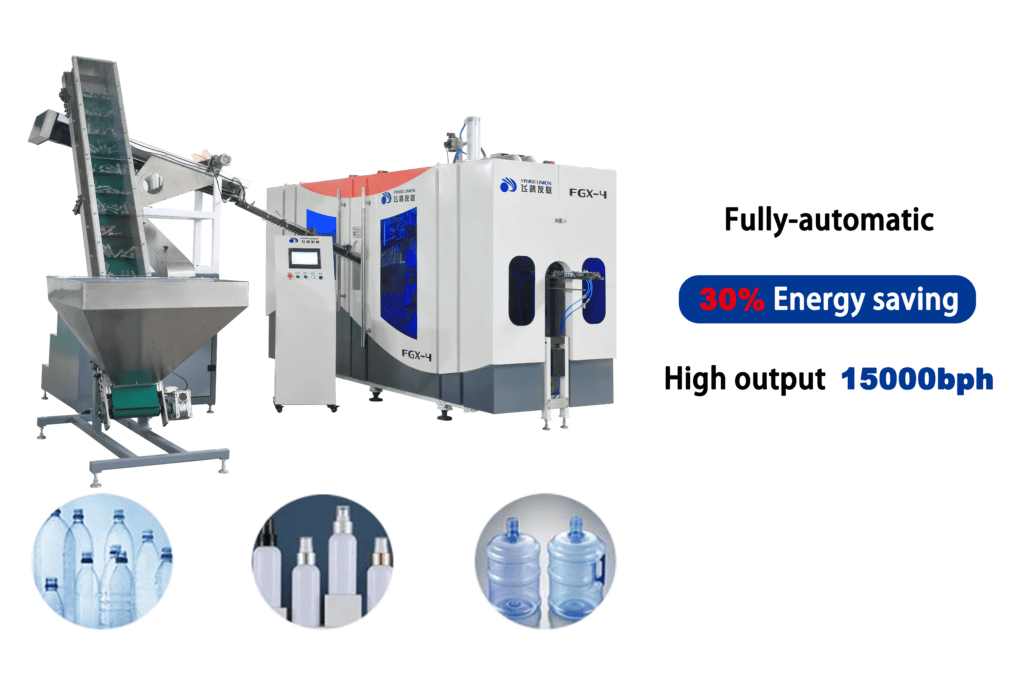

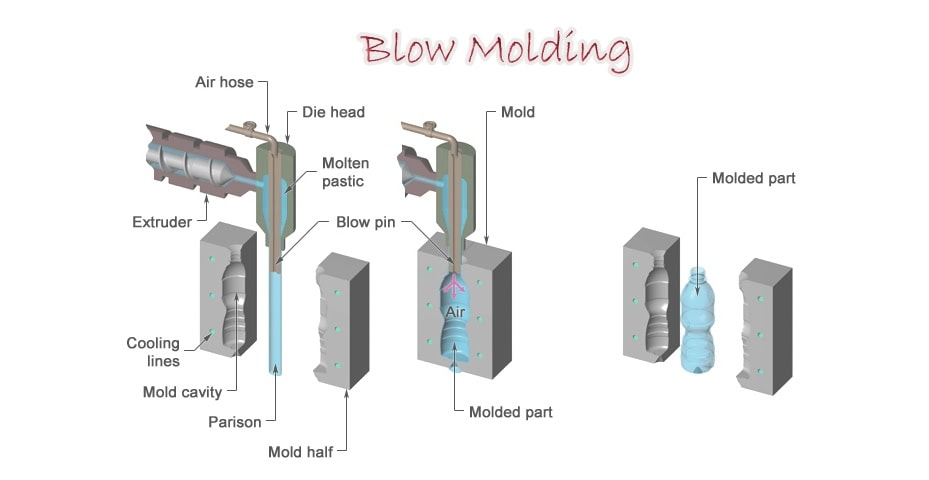

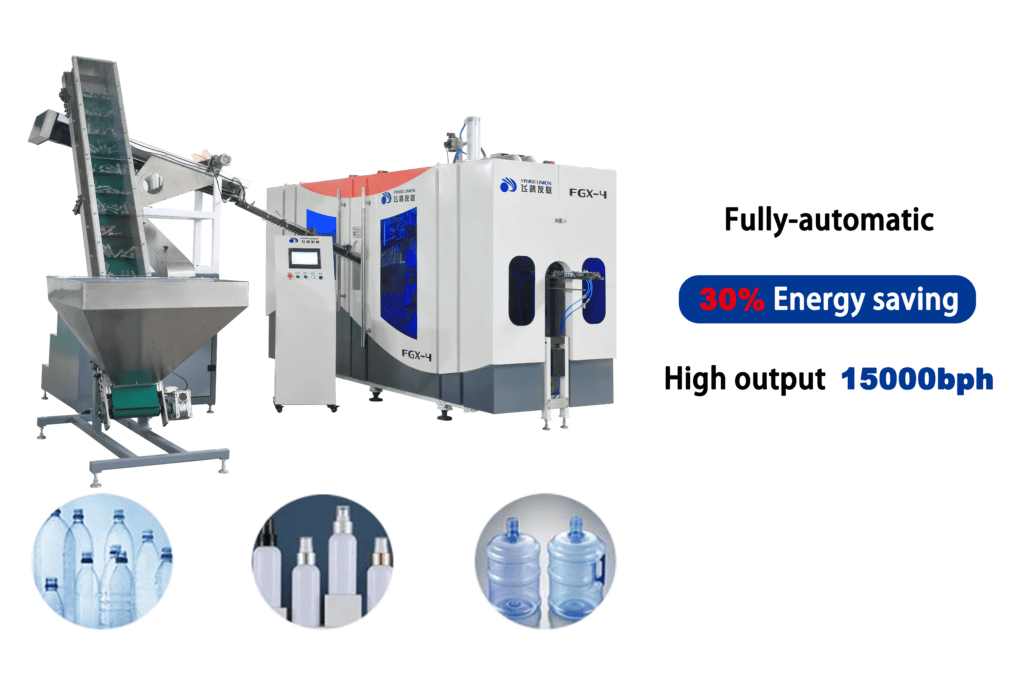

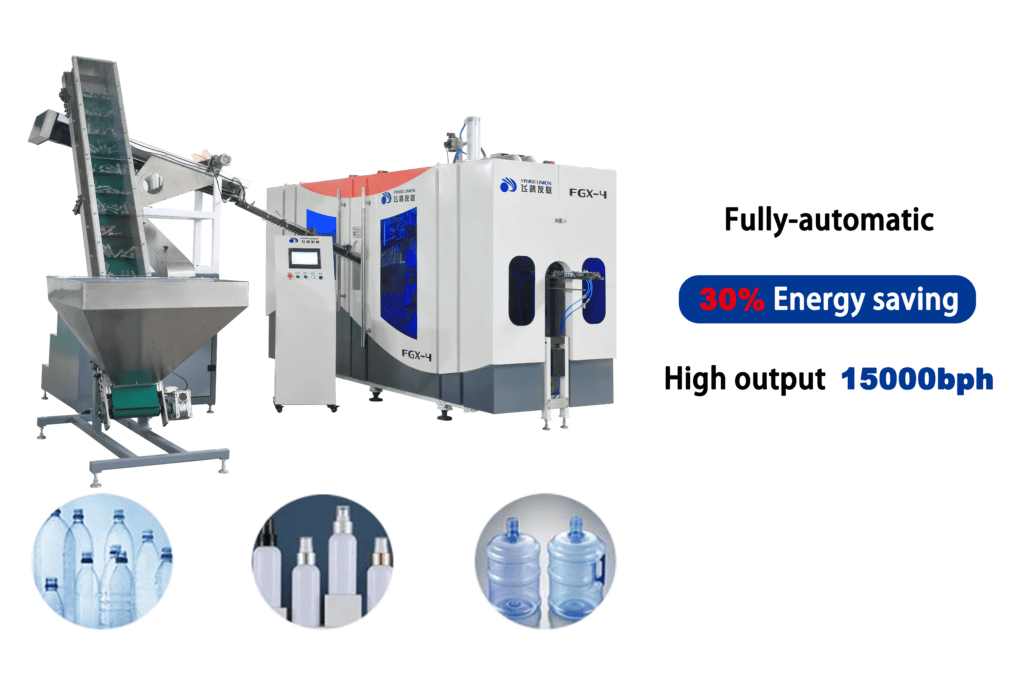

The next step is creating the PET (polyethylene terephthalate) bottles that hold the water. This is achieved using bottle blowing machines, which blowing preforms into lightweight, durable bottles.

Types of Bottle Blowing Machines

- Injection Stretch Blow Molding Machine : Produces high-clarity, uniform bottles. Ideal for premium brands.

- Extrusion Blow Molding Machine: Cost-effective for larger containers but less precise.

How It Works:

- Preforms (tube-shaped PET blanks) are heated and placed into molds.

- Compressed air is injected, stretching the preform into the mold’s shape.

- The bottle cools and is ejected for quality checks.

Top Brands:

- Sidel: Renowned for high-speed ISBM machines.

- FaygoUnion: Offers energy-efficient models with IoT integration.

4. Filling and Capping Machine: Precision and Hygiene

Once bottles are formed, they move to the filling stage. Modern filling machines ensure accuracy and prevent contamination.

Filling Technologies

- Gravity Fillers: Simple, low-cost systems for still water.

- Piston Fillers: High-speed volumetric filling for carbonated water.

- Aseptic Fillers: Sterile environments for extended shelf life.

Capping Systems:

- Screw Cappers: For standard screw-top lids.

- Snap Cappers: For sports bottles with flip-top lids.

Leading Manufacturers:

- KHS Group: Modular fillers with CIP (Clean-in-Place) systems.

- Serac: Aseptic filling solutions for sensitive products.

5. The Game-Changer: Blowing-Filling-Capping 3 in 1 Integrated Machines

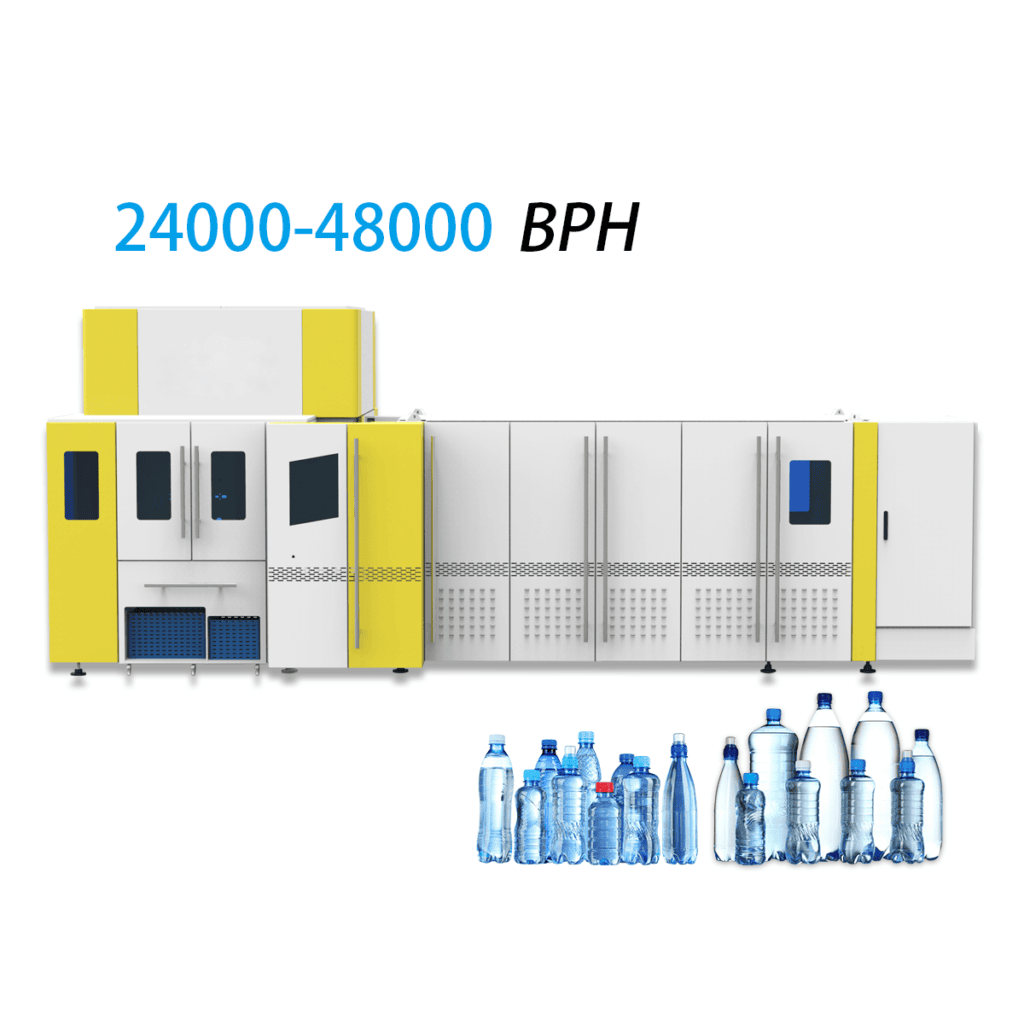

For businesses prioritizing efficiency and reducing contamination risks, blow-fill-seal integrated machines are a breakthrough. These systems combine bottle molding, filling, and capping into a single automated process.

Advantages of Blow-Fill-Seal Technology

- Space Savings: Eliminates separate machines for blowing, filling, and capping.

- Reduced Contamination: Seamless process minimizes human contact.

- Lower Operational Costs: 30–50% less energy and labor.

- Faster Production: 12000 to 72,000 bottles per hour.

How It Works:

- PET granules are melted and extruded into a parison (hollow tube).

- The parison is blown into a mold, forming the bottle.

- Immediately, purified water is injected into the newly formed bottle.

- The bottle is sealed with a cap before ejection.

Top 3 in 1 Blowing Filling Capping Machine Manufacturers:

- Rommelag: Industry leader in aseptic BFS machines.

- FAYGOUNION: Compact systems for small to mid-sized producers.

6. Packaging and Labeling Machinery

The final stage involves packaging bottles into shrink wraps, cartons, or crates for distribution.

Key Equipment:

- Shrink Wrapping Machines: Use heat to apply plastic film.

- Case Packers: Automate bottle arrangement into boxes.

- Labeling Machines: Apply branded labels with QR codes or nutritional info.

Innovative Solutions:

- Krones’ Variopac Pro: Combines wrapping, boxing, and palletizing.

- Sidel’s Rollquattro Labeler: High-speed labeling for round and flat bottles.

7. Quality Control and Sustainability Practices

Modern production lines integrate advanced sensors and AI-driven systems to monitor:

- Leak Detection: Laser sensors identify faulty seals.

- Weight Checks: Ensure consistent fill volumes.

- Material Recycling: PET scrap is reused to minimize waste.

8. Why Invest in Advanced Bottled Mineral Water Production Equipment?

Adopting technologies like blow-fill-seal integrated machines and IoT-enabled systems offers:

- Scalability: Easily adjust production volumes.

- Compliance: Meet FDA, EU, and WHO standards.

- Brand Reputation: Deliver consistent quality to build consumer trust.

Conclusion

The bottled water production process demands precision, hygiene, and cutting-edge equipment. From advanced water treatment systems to revolutionary blowing-filling-capping 3 in 1 machines, investing in the right technology ensures operational efficiency and product safety. For businesses aiming to dominate search rankings, optimizing content around keywords like “blow molding machines,” “bottled water filling systems,” and “blow-fill-seal technology” will attract targeted traffic and establish authority in this competitive industry.

By staying ahead with innovative solutions like integrated BFC systems, manufacturers can reduce costs, boost output, and meet the soaring global demand for bottled water.

]]>

Overview of Bottled Water Types

Bottled water comes in several varieties, each catering to specific preferences and uses. Broadly speaking, these types include:

- Purified Water: Water that has undergone filtration or treatment to remove impurities.

- Distilled Water: Water purified through the distillation process, leaving it free from minerals and contaminants.

- Mineral Water: Water sourced from natural springs, rich in essential minerals.

Each type serves a unique purpose, whether for everyday hydration, medical applications, or added health benefits.

What is Purified Water?

Purified water is water that has been treated to remove impurities such as chemicals, bacteria, and dissolved solids. Common methods of purification include:

- Reverse Osmosis: A process where water is forced through a semipermeable membrane, removing contaminants.

- Carbon Filtration: A method using activated carbon to absorb impurities and improve taste.

- Deionization: A chemical process that removes ionized particles like salts and metals.

Benefits of Purified Water:

- Clean and safe for consumption.

- Neutral taste, making it ideal for cooking and beverages.

- Widely available and affordable.

Purified water is a popular choice for daily hydration and is often used as the base for other types of bottled water.

What is Distilled Water?

Distilled water undergoes a specific purification process called distillation. This involves boiling the water to produce steam, which is then cooled and condensed back into liquid form. This process removes virtually all impurities, including minerals, bacteria, and chemicals.

Benefits of Distilled Water:

- Free of minerals, making it ideal for medical applications and appliances like humidifiers and steam irons.

- Suitable for individuals on strict diets requiring low-mineral water.

Drawbacks of Distilled Water:

- Lack of minerals can result in a flat taste.

- Not ideal for long-term hydration due to the absence of essential nutrients.

Distilled water is highly specialized and commonly used in laboratories, medical facilities, and for specific household appliances.

What is Mineral Water?

Mineral water is sourced from natural springs and contains naturally occurring minerals like calcium, magnesium, and potassium. These minerals are not added artificially but are naturally present due to the water’s journey through underground rocks and soil. Here is how to add minerals to water.

Benefits of Mineral Water:

- Contains essential minerals beneficial for health.

- Offers a distinct, refreshing taste.

- Often marketed as a premium product for health-conscious consumers.

Popular Uses of Mineral Water:

- Hydration with added health benefits.

- Preferred by athletes and individuals seeking mineral-rich diets.

Mineral water is a luxurious option that appeals to those looking for natural hydration with added nutrients.

Key Differences Between Purified, Distilled, and Mineral Water

Understanding the distinctions between these types of bottled water can help you choose the right one for your needs. Here’s a comparison:

| Feature | Purified Water | Distilled Water | Mineral Water |

|---|---|---|---|

| Source | Tap or natural sources | Tap or natural sources | Natural springs |

| Processing Method | Filtration, deionization, reverse osmosis | Distillation | No additional processing |

| Mineral Content | Minimal | None | High |

| Taste | Neutral | Flat | Refreshing, natural |

| Uses | General hydration, cooking | Medical, appliances | Hydration, health benefits |

How Bottled Water is Made

The production process for bottled water varies depending on the type:

- Collection: Water is sourced from municipal systems, natural springs, or underground aquifers.

- Filtration and Treatment:

- For purified water: Filtration and reverse osmosis are used to remove impurities.

- For distilled water: Water is boiled, and steam is collected to remove minerals.

- For mineral water: Water undergoes minimal treatment to preserve its natural mineral content.

- Bottling and packaging:

- Use the 3 in 1 blow-fill-cap machine to complete the production of blowing, filling and packaging of bottled water.

Which Drinking Water is Better for You?

The best type of water depends on your preferences, lifestyle, and health needs. Here’s a guide:

- Purified Water:

- Ideal for daily hydration and cooking.

- Affordable and widely available.

- Great for areas with poor water quality.

- Distilled Water:

- Suitable for medical purposes and appliances.

- Recommended for individuals requiring mineral-free water.

- Avoid long-term consumption due to lack of nutrients.

- Mineral Water:

- Best for health-conscious individuals seeking natural minerals.

- Great for athletes and those with mineral deficiencies.

- Premium choice for hydration with added health benefits.

Conclusion

Choosing the right type of bottled water requires an understanding of the differences between purified, distilled, and mineral water. While purified water is a versatile and economical choice for everyday use, distilled water serves specialized purposes, and mineral water offers a natural and nutrient-rich hydration option. By knowing your bottled water, you can make informed decisions that suit your health and lifestyle needs. Stay hydrated and choose wisely!

]]>

Understanding PET Bottle Design Basics

Material Overview

PET, or polyethylene terephthalate, is a thermoplastic polymer known for its exceptional properties:

- Transparency: Allows for attractive product presentation.

- Durability: Resistant to impact and breakage.

- Lightweight: Reduces shipping costs and material usage.

- Recyclability: Aligns with global sustainability goals.

These characteristics make PET an ideal material for designing bottles that are both functional and visually appealing.

Types of PET Bottles

PET bottles cater to various industries and applications:

- Water Bottles: Focused on lightweight, simple designs for portability.

- Juice Bottles: Often designed with vibrant branding elements and specialized sealing mechanisms.

- Specialty Bottles: Custom designs for cosmetics, pharmaceuticals, and other niche markets.

Understanding the intended use of a PET bottle is the first step toward crafting a suitable design.

Guidelines for Designing Plastic PET Bottles

1. Ergonomics

Ergonomic designs ensure that the bottle is easy to hold, pour, and use. Consider factors like:

- Grip design to prevent slippage.

- Bottle size and shape tailored to target demographics.

- Ease of opening and resealing.

2. Aesthetics

A well-designed PET bottle should reflect the brand’s identity while appealing to consumers visually. Tips include:

- Incorporating brand logos, textures, or patterns into the bottle.

- Choosing shapes that stand out on shelves while being practical.

- Using color accents sparingly to highlight key features.

3. Functionality

Balancing style with practicality is essential. Ensure the design:

- Supports proper sealing to prevent leaks.

- Maintains structural integrity during storage and transport.

- Facilitates easy stacking for efficient logistics.

4. Structural Integrity

PET bottles must withstand mechanical stresses during filling, capping, and transportation. Key considerations include:

- Wall thickness consistency to avoid weak points.

- Incorporating ribs or indentations to enhance strength.

- Avoiding overly complex designs that compromise durability.

Incorporating Creativity in PET Bottle Design

Creative designs not only capture consumer attention but also differentiate brands in competitive markets. Here’s how:

- Custom Shapes: Unique contours, such as a curvy water bottle or a fruit-shaped juice bottle.

- Textured Surfaces: Embossed patterns or matte finishes for a premium feel.

- Innovative Features: Built-in straws, flip-top lids, or dual compartments for added functionality.

Creative designs can be achieved using custom molds, which allow for high levels of personalization in bottle shape and detailing.

Custom Mold Design for PET Bottles

Benefits of Custom Molds

Investing in custom molds enables brands to:

- Achieve unique designs that enhance brand recognition.

- Tailor bottles to specific requirements, such as capacity or functionality.

- Experiment with innovative shapes and textures.

Compatibility with PET Bottle Blowing Machines

Custom molds must align with the capabilities of PET bottle blowing machines to ensure efficient production. Factors to consider:

- Mold material: High-quality metals like aluminum or steel for durability.

- Precision engineering: Ensuring uniformity across all produced bottles.

- Machine settings: Adjustments for temperature, pressure, and cycle times.

Cost Considerations

While custom molds require an upfront investment, they offer long-term benefits through brand differentiation and increased consumer appeal. Work with experienced manufacturers to optimize cost without compromising quality.

PET Bottle Design for Specific Application

Mineral and Pure Water Bottles

Design considerations for water bottles include:

- Lightweight Construction: Reducing material usage without compromising durability.

- Simple Aesthetics: Clear and minimalist designs that emphasize purity.

- Eco-Friendly Features: Incorporating recycled PET or designing for reuse.

Juice Bottles

For juice bottles, focus on:

- Vivid Branding: Bright colors and bold shapes to appeal to consumers.

- Enhanced Sealing: Preventing oxidation to maintain product freshness.

- Unique Shapes: Differentiating from competitors while remaining functional.

Ensuring Manufacturability of PET Bottles

Design Compatibility with Blowing Machines

A successful PET bottle design must work seamlessly with blowing machines. Key aspects include:

- Uniform Wall Thickness: Preventing weak points or deformities during production.

- Optimized Neck Dimensions: Ensuring compatibility with caps and closures.

- Efficient Cycle Times: Simplifying designs to reduce production delays.

Common Pitfalls to Avoid

- Overly intricate designs that slow down production.

- Ignoring cooling requirements, leading to deformations.

- Failing to account for material shrinkage during the molding process.

Case Studies: Successful PET water and juice Bottle Design

Iconic Water Bottle Designs

- Brand A: Introduced a lightweight, ergonomic bottle with a textured grip for outdoor use.

- Brand B: Launched a 100% recycled PET bottle, appealing to eco-conscious consumers.

Creative Juice Bottle Designs

- Brand C: Developed fruit-shaped bottles for kids, increasing product appeal.

- Brand D: Utilized vibrant colors and embossed logos to stand out on crowded shelves.

These examples highlight the importance of aligning design choices with brand identity and consumer preferences.

Future Trends in Plastic Bottle Design

The PET bottle industry continues to evolve with advancements in technology and shifting consumer expectations. Emerging trends include:

- Sustainability: Increased use of recycled PET and biodegradable alternatives.

- Smart Features: Incorporating QR codes, NFC tags, or smart caps for enhanced consumer engagement.

- Customization: Growing demand for personalized bottle designs, especially in premium markets.

Conclusion

Effective PET bottle design is a blend of creativity, functionality, and manufacturability. By understanding material properties, aligning with manufacturing processes, and incorporating unique features, brands can create bottles that resonate with consumers and drive market success. Whether designing for water, juice, or specialty applications, following these guidelines ensures your PET bottles and cans stand out in a competitive industry.

Explore the PET bottle design options today and transform your packaging into a powerful marketing tool.

]]>

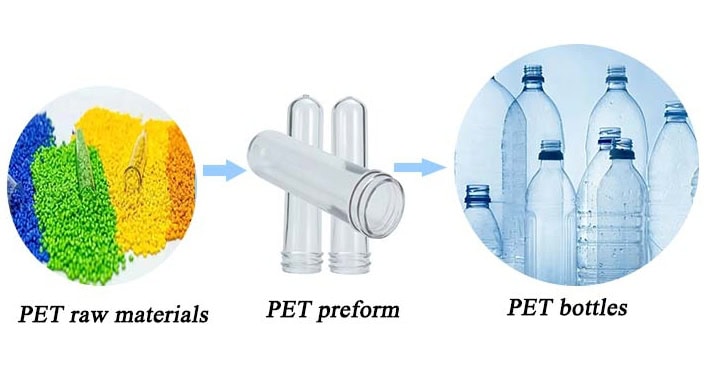

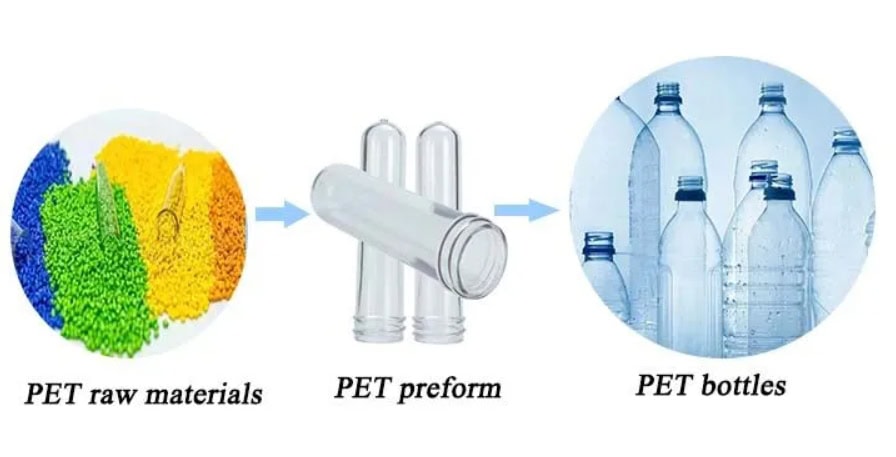

What Are PET Preform?

PET preforms are intermediate products made from polyethylene terephthalate (PET), a versatile and durable plastic. Shaped like test tubes, they are designed to be reheated and blow-molded into the desired bottle shape. PET preforms offer a cost-effective and efficient solution for producing high-quality plastic bottles.

Their design ensures uniformity, strength, and recyclability, making them a popular choice for packaging applications worldwide.

Applications of PET Preform

PET preforms are used across various industries, including:

- Beverage Industry: PET preforms are transformed into bottles for water, carbonated drinks, and juices.

- Pharmaceuticals: Packaging for liquid medicines and health supplements.

- Cosmetics: Containers for shampoos, lotions, and creams.

- Food Industry: Jars for sauces, oils, and condiments.

The adaptability of PET preforms ensures they meet the demands of diverse sectors, offering durability and aesthetic appeal.

Materials Used in PET Preform Manufacturing

PET preforms are manufactured using polyethylene terephthalate, a thermoplastic polymer known for its clarity, strength, and recyclability. Key characteristics of PET include:

- Lightweight: Reduces shipping costs and environmental impact.

- Recyclable: Supports sustainability initiatives.

- Durable: Resistant to impact and leakage.

These properties make PET an ideal choice for packaging applications where performance and sustainability are critical.

PET Bottle Preforms Manufacturing Process

The production of PET preforms involves several precise steps:

- Material Preparation: PET resin is dried to remove moisture, ensuring a smooth molding process.

- Injection Molding: The dried resin is melted and injected into a preform mold under high pressure.

- Cooling and Ejection: The preform is cooled to retain its shape and then ejected from the mold.

- Quality Inspection: Each preform is checked for consistency, dimensions, and transparency.

This highly controlled process ensures that PET preforms meet stringent quality standards, minimizing material waste and maximizing production efficiency.

Key Equipment: PET Preform Molding Machine and Bottle Blowing Machine

The manufacturing of PET preforms and their transformation into bottles rely on specialized machinery:

- PET Preform Molding Machines: Used to mold the resin into preforms. These machines are designed for high-speed and precision manufacturing.

- Bottle Blowing Machines: Heat the preforms and blow them into the desired bottle shape. These machines are crucial for ensuring uniformity and strength in the final product.

Advanced machinery integrates automation and energy-saving features, improving productivity and reducing operational costs.

Advantages of Using PET Bottle Preforms

PET preforms offer several benefits:

- Recyclability: PET can be recycled multiple times, reducing environmental impact.

- Cost Efficiency: Preforms are lightweight and easy to transport, lowering logistics costs.

- Durability: Resistant to impact, leaks, and chemical reactions.

- Versatility: Suitable for various shapes, sizes, and applications.

These advantages make PET preforms a preferred choice in the packaging industry.

PET Preforms for Drinking Water and Beverage Bottles

Water bottles are one of the most common applications for PET preforms. When you want to produce plastic beverage bottles or you want to setup a mineral water factory, bottle preforms are a necessityThe manufacturing process for these bottles involves reheating the preforms and blowing them into molds that define the bottle’s shape and size. Quality standards are critical in this application to ensure:

- Purity: No chemical leaching into the water.

- Strength: Withstanding transportation and handling.

- Clarity: Enhancing aesthetic appeal and consumer trust.

Challenges in Plastic Preform Manufacturing

While Plastic PET preforms are highly advantageous, their production comes with challenges:

- Material Sourcing: Ensuring consistent supply of high-quality PET resin.

- Precision Molding: Achieving uniformity and minimizing defects.

- Energy Consumption: Managing high energy use during molding and heating processes.

To overcome these challenges, manufacturers are adopting advanced technologies, such as energy-efficient machinery and process automation.

Future Trends in the PET Preform Industry

The Plastic PET preform industry is evolving with innovations aimed at sustainability and efficiency:

- Biodegradable PET: Development of eco-friendly materials to reduce environmental impact.

- Advanced Machinery: Integration of AI and IoT for smarter production processes.

- Customization: Growing demand for unique shapes and designs.

These trends are shaping the future of the packaging industry, making Plastic preforms an even more integral component.

Conclusion

Plastic PET Bottle preforms play a vital role in modern packaging, offering unmatched versatility, efficiency, and sustainability. From their use in water bottles to high-end cosmetic containers, PET preforms cater to diverse needs while supporting environmental initiatives. As the industry continues to innovate, PET preforms will remain a cornerstone of packaging solutions.

Explore the possibilities of Plastic PET preforms for your business today and embrace the future of packaging technology.

]]>

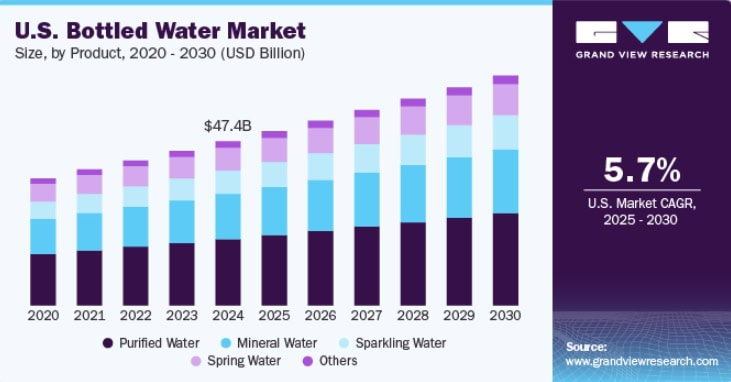

With relatively low investment requirements and the potential for high returns, a mineral water plant can be a lucrative option for entrepreneurs looking to enter the food and beverage industry. By starting a small water bottle factory, you can tap into this growing demand while contributing to public health by providing clean, pure drinking water.

In this comprehensive guide, we will walk you through the essential steps to set up a small mineral water plant, outlining costs, necessary equipment, production processes, and tips for running a successful business.

Understanding the Basics of Starting a Bottled Mineral Water Plant

Starting a water plant business involves a series of critical steps that must be followed for success. The first major consideration is site selection, as it directly impacts water quality, accessibility, and operational efficiency. Your plant should be located near a clean and abundant water source, whether it be from wells, springs, or municipal water supplies. Additionally, proximity to transport routes is essential for distributing the final product.

Once you’ve chosen an ideal location, you’ll need to secure the necessary permits and licenses to operate your mineral water plant. These legal requirements vary by country and region but typically include water extraction rights, environmental impact assessments, and health and safety compliance. Understanding these regulations beforehand will help avoid delays and prevent legal complications in the future.

Factors to Consider Before Starting a Small Mineral Water Factory

Before diving into the setup of a drinking water factory, it’s essential to carefully assess various factors to ensure your business operates efficiently and successfully.

- Water Source: The most important factor when build a mineral water plant is the water source itself. It must be clean, naturally filtered, and free from contaminants. Water quality is paramount, as it will directly impact the taste and safety of the final product.

- Location: The plant’s location should be close to the water source, with access to utilities like electricity and water supply. Additionally, it should be in a region with a reliable distribution network for delivering the bottled water to retailers or customers.

- Permits and Regulations: Obtaining the correct permits for your water bottle company is vital to ensure that your business meets local regulations for water extraction, health safety, and environmental standards. Compliance with these regulations helps build consumer trust and avoids legal issues.

Cost Breakdown for Setting Up a Small Mineral Water Plant

Setting up a small-scale water bottling plant requires careful financial planning. Below is a breakdown of the main costs involved in starting your mineral water company.

Subsection 1: Estimated Costs of Land, Equipment, and Initial Setup

- Land Cost: The cost of land varies greatly depending on location. For instance, in urban areas with limited space, land can be expensive. However, a water plant located in a less congested area may have lower land costs.

- Equipment: Major equipment includes water purification systems, water bottle blowing filling machines, capping and labeling machines, and packing systems. The price for these machines varies but can range from $100,000 to $300,000 depending on your production scale and the quality of the equipment.

Subsection 2: Operational Costs

- Electricity: Running a mineral water business requires a significant amount of energy, especially for machines like water purifiers, bottling machines, and packaging systems.

- Labor: The cost of labor varies depending on the region, but you’ll need employees for production, quality control, packing, and administration. A small-scale plant typically requires a team of 10-20 workers.

- Water Supply: While water may be relatively inexpensive if sourced locally, fees may apply depending on the water rights and legal regulations in your region.

Subsection 3: Additional Expenses

- Marketing: To stand out in a competitive market, it’s essential to allocate a budget for branding, packaging design, and promotional campaigns.

- Packaging and Distribution: Packaging materials (plastic bottles, caps, labels) represent ongoing expenses. Additionally, transportation costs for distributing bottled water to retailers or customers can add to the overall cost structure.

Choosing the Right Equipment for a Drinking Water Plant

Selecting the right equipment is crucial to ensure the smooth functioning of your mineral water factory. The main machinery involved includes:

- Water Purification Equipment: This includes reverse osmosis (RO) systems, UV sterilizers, and ozone disinfection machines, which ensure that the water is free from bacteria and contaminants.

- Water Bottle Blowing Machine: This water bottle manufacturing machine is essential for shaping the bottles from preforms, typically made from PET plastic, and can handle various bottle sizes.

- Filling and Capping Machines: These machines fill the purified water into the bottles and apply caps to ensure that the product remains sealed and uncontaminated.

- Labeling and Packaging Machines: These machines apply labels and pack the bottles into cases, ready for distribution.

When selecting equipment, consider factors like production capacity, automation levels, and long-term reliability. Opt for machines that require minimal maintenance but offer high-quality production output.

Setting Up the Production Process

The production process in a pure water plant typically follows these steps:

- Water Sourcing: Water is extracted from a natural source, well, or municipal supply.

- Water Purification: The water is treated through filtration and purification processes, such as reverse osmosis, UV sterilization, and ozone treatment, to remove any impurities and ensure it meets health and safety standards.

- Bottle Production: The water bottle manufacturing machine molds PET preforms into the desired bottle shape.

- Filling: The purified water is transferred into the bottles, ensuring that the amount of water is accurate and the bottles are not contaminated.

- Capping and Labeling: Bottles are sealed with caps and labeled with product information, including the brand name, nutritional information, and expiration date.

- Packaging: The filled and labeled bottles are packaged into boxes or crates for distribution.

Maintaining hygiene standards during production is vital to ensure the safety and quality of the product. Regular cleaning and sanitizing of equipment and facilities are necessary to prevent contamination.

Tips for Running a Profitable Bottled Water Business

Here are some key strategies to help make your bottled water business more profitable:

- Cost-Saving Strategies: Optimize operational efficiency by investing in energy-efficient machines, reducing waste, and sourcing materials in bulk.

- Efficiency Improvements: Implement automated systems to increase production speed, reduce labor costs, and minimize errors.

- Marketing and Branding: Strong branding and packaging are essential to stand out in a competitive market. Focus on quality, sustainability, and eco-friendly practices to appeal to consumers.

Legal Considerations and Compliance in the Water Bottling Industry

To ensure compliance, you must familiarize yourself with the regulations governing the mineral water industry, including:

- Water Testing: Regular water testing is essential to ensure the water meets health standards. Testing helps detect any harmful contaminants and ensures the product is safe for consumption.

- Health Safety Standards: Compliance with health regulations, including proper hygiene during the bottling process, is crucial for the safety of your consumers.

- Product Labeling: The labeling should comply with local regulations, including details like ingredients, brand name, net weight, and expiration date.

Adhering to these standards not only ensures legal compliance but also builds consumer trust and confidence in your product.

Challenges in Setting Up a Mineral Drinking Water Factory

Some common challenges faced when start a mineral water plant include:

- Water Contamination: Even with purification systems, water can sometimes become contaminated. Regular testing and maintenance of the water source are critical.

- High Operational Costs: Energy costs and the price of quality equipment can be high, so it’s important to manage these expenses efficiently.

- Competition: The bottled water market is highly competitive. To stand out, you’ll need a strong brand, high-quality products, and effective marketing.

Conclusion: Is a Small Mineral Water Plant Right for You?

Setting up a mineral water factory can be a profitable and rewarding business venture, but it requires careful planning, significant investment, and ongoing operational management. By understanding the costs, selecting the right equipment, and adhering to industry standards, you can create a successful water plant business.

If you’re ready to take the next steps, research local regulations, assess your financial capabilities, and invest in quality equipment to ensure the long-term success of your mineral water business.

]]>

In this article, we will walk you through 8 essential tips to help you start a bottled water company, from conducting market research to selecting the right equipment and developing a strong brand presence. These tips will provide valuable insights into how to establish a successful water bottling plant, ensuring your venture meets industry standards while tapping into the booming bottled water market.

How to Start a Bottled Water Plant

8 Tips You Need to Know

Tip 1: Conduct Market Research and Feasibility Study

Before you start a bottled water business, it is critical to conduct thorough market research and a feasibility study. Understanding the demand, competition, and consumer preferences is essential for shaping your business strategy.

Consider factors such as regional water availability, local preferences for bottle size, and pricing strategies that appeal to your target demographic. Research local and international bottled water brands, noting what sets them apart in terms of product quality, packaging, and marketing.

Successful water bottle companies like Coca-Cola’s Dasani and Nestlé’s Pure Life provide useful case studies in effective market positioning. These companies have tapped into the global bottled water market by combining quality products with clever branding and distribution channels, which can serve as inspiration for your business.

Tip 2: Choose the Right Bottled Water Business Model

When you start a bottled water plant, you must decide which business model aligns with your goals. There are several options to consider:

- Branded Water: Creating your own brand and developing unique packaging allows for differentiation in the competitive market. You’ll need to build a brand identity, and effective marketing will be key.

- Private Label: This model involves producing water under another brand’s name, offering less upfront marketing cost but with lower profit margins.

- Bulk Supply: Selling large quantities of water to wholesalers or retailers can be highly profitable but may limit brand recognition.

Each model has pros and cons, with factors such as market demand, production capacity, and marketing budget influencing your decision. Assess your financial situation and market conditions before settling on the most appropriate model for your water bottle company.

Tip 3: Legal and Regulatory Compliance

Starting a water bottling plant requires careful attention to legal and regulatory compliance. Obtaining the necessary permits and licenses is critical to ensure the business operates within the law. You will need to familiarize yourself with local and international water safety standards, including food safety, hygiene standards, and environmental regulations.

For example, water bottling plants are often required to comply with regulations like the U.S. Food and Drug Administration’s (FDA) bottled water regulations, or the European Union’s water quality standards. Your facility will need to meet strict health and safety codes, including water treatment and filtration processes.

Labeling requirements are also essential for clarity regarding the origin and contents of the bottled water. Be sure to follow regional labeling laws to avoid potential legal issues.

Tip 4: Secure a Suitable Location and Facility

Choosing the right location and facility is one of the most important steps when starting a bottled water business. Ideally, your water plant should be located near a reliable and clean water source. This proximity helps reduce costs and ensures consistent quality.

Your facility should have adequate space for machinery, storage, and distribution. Factors to consider include access to transportation infrastructure, electricity, water testing, and environmental impact assessments.

Water source testing is crucial to ensure the water meets health and safety standards. Many bottled water companies conduct regular water quality tests and obtain government approval before bottling. Additionally, your facility will need to be equipped for proper storage, including temperature control and protection from contamination.

Tip 5: Invest in the Right Equipment and Technology

The machinery used in your plant is essential to maintaining production quality and efficiency. Key equipment for plastic water bottle manufacturing includes:

- Water Treatment Equipment: This includes reverse osmosis, UV sterilization, and ozone disinfection to ensure clean, safe water.

- Bottle Production Equipment: Bottle blowing machines are crucial in processing PET preforms into bottles, providing flexibility in bottle sizes, including the popular 300ml, 500ml, and 600ml sizes.

- Bottling Machines: These machines fill purified water into bottles, ensuring accurate metering and preventing contamination. Washing and filling machines also play an important role in the bottling process.

- Capping and Labeling Machines: These machines apply caps and labels efficiently, ensuring product consistency and branding.

- Bottle Packing Machines: Essential for packaging bottled water into cases for distribution.

When selecting equipment, you need to consider production capacity, quality, and budget. Automation can significantly improve scalability, reduce human error, and increase production speed. For small to medium operations, the three-in-one blowing-filling-capping combi block machine can be an ideal solution. This machine occupies minimal space and is easy to maintain while providing high-quality production capabilities.

Tip 6: Develop a Strong Branding and Marketing Strategy

Creating a unique brand identity is crucial in the competitive bottled water market. Design an eye-catching label and packaging that stands out on store shelves. Consider incorporating sustainable elements, such as eco-friendly packaging, to appeal to environmentally conscious consumers.

Marketing strategies should include both online and offline efforts. Social media, influencer marketing, and SEO can help you build an online presence. Offline strategies, including partnerships with retailers and event sponsorships, can enhance brand recognition.

Sustainability in branding has become increasingly important. Packaging made from recycled materials or offering bottle return programs could appeal to your target audience while promoting your commitment to environmental responsibility.

Tip 7: Establish Distribution Channels

Effective distribution channels are key to the success of your water bottle company. Your options include direct sales, partnerships with retailers, or leveraging online delivery services.

Building relationships with distributors can expand your reach and ensure that your bottled water reaches customers efficiently. Be sure to focus on customer satisfaction by ensuring timely delivery and maintaining product quality. As you scale, consider creating a strong supply chain to optimize inventory and logistics.

Tip 8: How Much Does It Cost to Start a Bottled Water Company?

The startup costs for a bottled water business can vary depending on location, scale, and equipment choices. Key costs include:

- Factory Rental Cost: Rent for factory space depends on the region and the size of the facility. Larger locations or those closer to water sources may be more expensive.

- Equipment Costs: Major equipment like water treatment systems, bottle blow molding machines, filling machines, and packaging machinery will require significant investment. Prices for these can vary, with smaller bottling machines costing around $30,000 and larger systems reaching upwards of $100,000.

- Labor Costs: Labor costs also vary by region, with wages depending on local economic conditions. On average, you should account for employees in production, quality control, packaging, and administration.

The overall cost of starting a water factory can range from $200,000 to several million dollars, depending on the scale and technology chosen.

Conclusion

Starting a bottled water business requires careful planning and investment. By conducting thorough market research, selecting the right business model, ensuring legal compliance, and investing in the proper machinery, you can lay the foundation for a successful business. Building a strong brand and marketing strategy, establishing efficient distribution channels, and understanding the startup costs are essential steps in achieving profitability in the bottled water business.

Explore bottled water machines and industry solutions to kickstart your venture today and tap into the rapidly growing bottled water market.

]]>

What Minerals Are Found in Water?

Before we delve into how to add minerals back into water, it’s important to understand the essential minerals that naturally occur in water. These minerals contribute to the taste and health benefits of water. The most common minerals found in natural mineral water include:

- Calcium: Important for strong bones and teeth.

- Magnesium: Supports muscle and nerve function, and helps regulate blood sugar levels.

- Sodium: Essential for maintaining fluid balance in the body.

- Potassium: Helps regulate blood pressure and fluid balance.

- Bicarbonates: Help neutralize acids in the body and balance pH levels.

When you purify water using an RO system, these vital minerals are removed, leaving behind water that is free of contaminants but also devoid of these essential nutrients. To restore the balance, you need to add the right minerals back into the water.

How to Add Minerals to RO Water Naturally

If you have a reverse osmosis system and want to add minerals back into the purified water, there are several natural methods to do so. Below are some effective ways to add minerals to water without compromising its purity:

1. Use Mineral Drops or Mineral Salts

One of the easiest ways to add minerals back into RO water is by using mineral drops or mineral salts. These products are specially formulated to restore essential minerals like calcium, magnesium, and potassium to your water. Simply add a few drops or a pinch of the mineral salt to your glass of water or to the entire water supply in your system.

Benefits:

- Easy to use

- Customizable based on your mineral needs

- Quick and efficient

2. Add a Mineral Filter to Your RO System

A more permanent solution is to install a mineral filter alongside your existing RO system. These filters are designed to add essential minerals back into the water after the purification process. Some advanced RO systems come with built-in mineral filters, allowing you to customize the mineral content of your water.

Benefits:

- Continuous addition of minerals with every use

- Efficient and automatic process

- No need to manually add minerals

3. Use Mineral Stones or Mineralized Ceramic Balls to add minerals

Mineral stones or ceramic balls are another natural way to add minerals to water. These small stones or balls are placed in the water, where they release minerals like calcium and magnesium into the water. They’re a great solution for people who want a chemical-free way of enriching their water.

Benefits:

- Chemical-free

- Long-lasting

- Improves the taste of water

4. Infuse Water with Natural Mineral-Rich Ingredients

If you’re looking for a more natural way to add minerals to your water, you can infuse it with ingredients like Himalayan salt, lemon slices, or cucumber. While this method is not as effective as other methods, it can add a small amount of minerals and a refreshing flavor.

Benefits:

- All-natural

- Refreshing and hydrating

- Great for flavoring water

Using a Mineral Water Machine

A mineral water machine, also known as a mineralizer, is an innovative appliance that can help restore the mineral content of your purified water. These machines are designed to add back essential minerals like calcium and magnesium after the RO process. By adjusting the settings, you can control the mineral content according to your preferences.

Benefits:

- Precise control over mineral content

- Convenient for households and businesses

- Provides high-quality, mineral-enriched water

Mineral Water Machine

The Role of Bottled Mineral Water

Bottled mineral water is a convenient and popular option for people who don’t have access to an RO system or want to enjoy mineral-rich water without the hassle of adding minerals themselves. Bottled mineral water is naturally enriched with minerals from underground sources and offers a pure, healthy, and refreshing alternative to regular tap water.

Benefits of Bottled Mineral Water:

- Contains naturally occurring minerals

- Convenient and easy to access

- Often comes in various flavors and types for consumer preference

What minerals are in bottled drinking water?

Which minerals are added to mineral water depends on the manufacturer, but common ones include: magnesium sulfate, potassium chloride, potassium bicarbonate, calcium chloride, and sodium bicarbonate. Bottled water companies add these minerals to purified water to improve the taste, which can be “flat” on its own. The mineral content of bottled water also affects its flavor, so waters from different sources taste different.

How are bottled mineral water produced?

The production of bottled mineral water involves several key steps to ensure water purity and efficient packaging. First, water is sourced from a natural spring and undergoes purification, typically through filtration and UV treatment to remove impurities and bacteria. After purification, the water is stored in large tanks before being transferred to the bottling station.

At the bottling station, bottles are sterilized, often using ozone or UV light to ensure hygiene. The purified water is then filled into bottles using automatic filling machines, ensuring accuracy and reducing wastage. The bottles are sealed with caps, and the final step involves labeling and packaging for distribution.

FAYGO UNION’s new blow-fill-capping machine combines blow molding, filling, and capping in a single compact unit. This innovative equipment streamlines the production process, offering significant space and cost savings. With just one small machine can produce high-quality bottled mineral water efficiently. The blow-fill-capping machine is designed for high-speed operation, ensuring a consistent output while maintaining stringent hygiene standards. This is a game-changer for businesses looking to optimize their bottled water production line with minimal investment and maximum output.

]]>

China TOP Plastic Bottle Blowing Machine Manufacturers

China has emerged as a global hub for manufacturing plastic bottle blowing machines, owing to its competitive pricing, onstantly updated technology and strong production capacity. Whether you’re a small business owner or a procurement manager for a multinational corporation, choosing the right manufacturer is critical for your operations. In this article, we present a comprehensive list of the top plastic pet bottle blowing machine manufacturers in China for 2024, along with insights into the technologies and trends shaping the industry.

Key Considerations When Selecting a Plastic Bottle Blowing Machine Manufacturer

- Technology and Innovation

Look for manufacturers offering state-of-the-art solutions such as energy-efficient machines, high-speed production capabilities, and advanced stretch blow molding technology. These features not only enhance productivity but also reduce operational costs.

- Production Capacity

Ensure the manufacturer can meet your specific production needs, whether you’re making thousands or millions of bottles annually. - Certifications and Standards

International certifications like ISO and CE guarantee the quality and safety of the machines.

- After-Sales Support

Reliable after-sales support, including warranties, spare parts availability, and maintenance services, is essential for long-term machine performance.

Top 10 Plastic Bottle Blowing Machine Manufacturers in China (2024)

1.Krones China

Specialties: Turnkey solutions for beverage packaging

Features:

- Renowned for premium quality and precision engineering.

- Pricing is on the higher side, making it less attractive for smaller manufacturers.

- The complexity of products may require specialized training for operators.

2. King Machine

Specialties: Automatic bottle blowing machines

Features:

- Specializes in high-speed water bottle production

- Machines may not be suitable for high-volume, large-scale production.

- Limited innovation in advanced automation or cutting-edge technologies.

3.FAYGO UNION Machinery

Specialties: High-speed PET bottle blowing machines, Blowing-Flling-Capping combiblock machine

Features:

- Energy-saving and high-efficiency, moderate price

- Expertise in small bottled water production lines.

- Provide after-sales service for global customers

4.Ningbo Daxie Blowing Machinery

Specialties: extrusion blow molding machines

Features:

- offering solutions for large and complex container shapes,

- Limited focus on smaller containers.

- After-sales support may be less robust in non-Asian markets.

5.Demark Machinery

Specialties: PET preform and blowing machine integration

Features:

- Specializes in preform to blow molding integration for smooth operations

- Might lack customization options compared to other manufacturers.

6.Suzhou Yuda Machinery

Specialties: Fully automatic PET bottle production lines

Features:

- Competitive pricing for Fully automatic and customizable.

- Cost-effective options for small-scale operations and startups.

- Robust and durable machines for long-term use.

Overview of Plastic Bottle Blowing Technologies

Stretch Blow Molding

A widely used technology where PET preforms are heated and stretched into bottle molds. Ideal for producing lightweight, durable bottles.

Extrusion Blow Molding

This technique is perfect for manufacturing bottles with complex shapes. It involves extruding molten plastic into a mold and inflating it to form the desired shape.

Injection Blow Molding

Best for small, high-precision containers. This process combines injection molding with blow molding for intricate designs.

Why Choose Chinese Manufacturers?

1. Cost-Effectiveness

Chinese manufacturers offer competitive pricing without compromising on quality, making them the top choice for global buyers.

2. Advanced Technology

Many manufacturers invest heavily in R&D, integrating automation, AI, and eco-friendly innovations into their machines.

3. Strong Supply Chain

With well-established supply chains and logistics networks, Chinese manufacturers ensure timely delivery and consistent quality.

How to Import Plastic Machines from China manufacturers

- Research Manufacturers: Start by researching reputable manufacturers in China. Verify their credentials, certifications (like ISO), and reviews from other international clients.

- Request Quotes and Samples: Contact multiple suppliers to request quotes and machine samples. This will help you compare prices, quality, and the manufacturer’s reliability.

- Check Import Regulations: Understand your country’s import regulations for industrial machinery, including tariffs, duties, and required certifications.

- Negotiate Terms: Discuss payment terms, warranties, and after-sales support to avoid future complications. Ensure that spare parts are easily available.

- Arrange Shipping: Once you finalize the purchase, work with a freight forwarder to handle shipping, customs clearance, and delivery logistics to ensure smooth and timely delivery

China continues to lead the global market for Plastic machinery and beverage machinery market in 2024, offering competitive pricing, and robust after-sales support. Whether you’re seeking precision, efficiency, or sustainability, the manufacturers on this list provide exceptional options.

]]>

What is PET Plastic?

Polyethylene terephthalate (PET) is a type of polyester widely used in the packaging industry. It is favored for its strength, chemical resistance, and excellent ability to preserve the freshness of liquids and food products. PET is also highly recyclable, contributing to its appeal as an environmentally friendly material in comparison to other single-use plastics.

Typical applications of PET include:

- Bottled water and soft drink containers

- Food packaging

- Synthetic fibers for clothing and textiles

Understanding BPA and Its Health Concerns

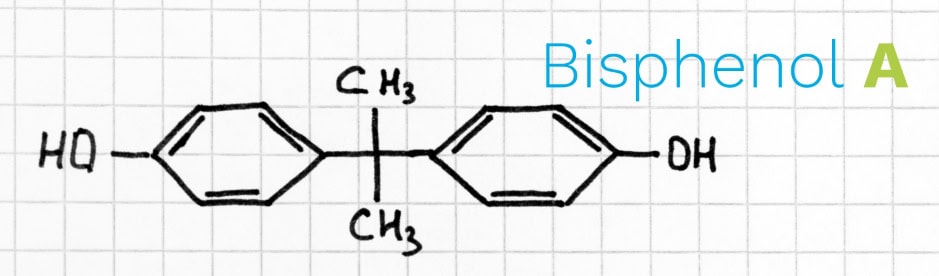

BPA, or bisphenol A, is a chemical compound often used in manufacturing polycarbonate plastics and epoxy resins. It gained notoriety due to studies linking it to potential health risks, including hormonal disruption, cardiovascular issues, and developmental problems in children. These concerns led to a widespread consumer demand for “BPA-free” products, especially in the food and beverage industry.

Is PET Plastic BPA Free?

Yes, PET plastic is 100% BPA-free. Unlike polycarbonate plastics, PET does not use bisphenol A in its production process. This makes it a safe choice for bottled water and other food-grade applications.

There are no chemical phthalates or bisphenol A (BPA) in PET plastic, and therefore PET plastic does not leach these substances. PET plastic is approved as safe contact by FDA and similar regulatory agencies throughout the world, and has been for more than 30 years.

Is PET Plastic Safe for Drinking Water?

The safety of PET for drinking water has been studied extensively by health and regulatory authorities around the world. According to the FDA, European Food Safety Authority (EFSA), and other regulatory bodies, PET is a safe material for holding drinking water and other beverages.

PET is an inert material, meaning it does not react with water or other liquids stored inside. This makes it an ideal choice for bottled water, as it does not affect the taste or quality of the liquid. Unlike other types of plastic that may release harmful chemicals or toxins into the contents over time, PET remains stable and does not leach substances into the water.

In fact, PET is one of the most reliable plastics for food and beverage storage. It is resistant to impacts and can withstand the rigors of transportation and handling without breaking or leaking. Furthermore, PET is highly resistant to moisture, which helps preserve the freshness of bottled water and extends shelf life.

Reusing PET Bottles: Best Practices for Safety

While PET is safe for single-use applications, many consumers wonder whether it is safe to reuse PET water bottles. While PET itself is non-toxic, reusing a plastic bottle multiple times can lead to wear and tear, potentially creating opportunities for bacteria to accumulate in the bottle. Avoid Heating PET Bottles,as this can cause degradation of the plastic and potentially lead to harmful chemical release.

If you plan to reuse a water bottle frequently, consider switching to a reusable stainless steel or glass bottle, which is designed for long-term use and is generally more durable than PET.

Comparison: PET vs Other Plastics

When choosing a plastic bottle, it is important to understand the differences between PET and other materials:

- Polycarbonate Plastics: Often associated with BPA, polycarbonate is now less commonly used due to health concerns.

- High-Density Polyethylene (HDPE): Durable and BPA-free, but less transparent than PET.

- Glass and Stainless Steel: While these are BPA-free and reusable, they are heavier and less convenient for on-the-go use.

PET stands out as a lightweight, BPA-free option that balances safety, functionality, and environmental responsibility.

Common Myths About PET Plastic

Despite its widespread use and safety, there are several myths and misconceptions about PET plastic. Let’s take a look at some of the most common ones:

- Myth #1: PET Bottles Release Harmful Toxins Over Time.

This is false. PET is stable and does not leach harmful chemicals under normal use conditions. As mentioned earlier, PET is a BPA-free plastic, and no harmful substances are released into the water or other liquids it contains. - Myth #2: PET Plastic is Harmful to the Environment.

While it’s true that plastic pollution is a major environmental issue, PET is one of the most recyclable plastics available today. In fact, PET has a high recycling rate, and products made from recycled PET (rPET) are used in a wide range of applications, from clothing to new plastic containers. - Myth #3: PET Bottles Are Not Safe for Hot Liquids.

PET is safe for storing water and other beverages at room temperature. However, it is not suitable for storing hot liquids, as heat can cause the plastic to deform or degrade. PET bottles should never be used for hot beverages, as this can compromise their safety.

Conclusion on the safety of PET plastic

In conclusion, PET plastic is BPA-free and safe for bottled water. It is a reliable and trusted material used worldwide in the packaging of beverages. With its non-toxic, durable, and recyclable properties, PET has become the material of choice for bottled water manufacturers.

While concerns about plastic safety are valid, PET stands out as one of the safest options for food and beverage packaging. Whether you’re looking to purchase bottled water or considering manufacturing plastic bottle, rest assured that PET plastic is a safe, sustainable, and BPA-free solution.

If you’re a manufacturer looking to invest in bottling equipment, including bottle blowing machines, bottling machines, and packing machines, FAYGO UNION offers high-quality solutions to help you meet your production needs with the utmost safety and efficiency. Contact us today to learn more about our state-of-the-art equipment and how we can assist you in starting your bottled water business.

Plastic bottles are an essential part of modern life, used widely in packaging for mineral water,beverages, cleaning products, and personal care items. But have you ever wondered, how are plastic bottles made? This comprehensive guide will explain the materials, stages of production, and technologies involved in the plastic bottle manufacturing process. Whether you’re curious about how plastic PET/HDPE bottles are made or considering starting your own production line, this article has everything you need to know.

What Are Plastic Bottles Made Of?

Plastic bottles are made from a variety of plastics, each selected for its specific properties and intended use. Common materials include:

- Polyethylene Terephthalate (PET): A lightweight, durable, and recyclable thermoplastic polymer widely used for water and soda bottles. PET is derived from a chemical reaction between ethylene glycol and terephthalic acid. Is PET Plastic BPA Free? The Safety of Bottled Water

- High-Density Polyethylene (HDPE): Known for its sturdiness and resistance to chemicals, HDPE is used in milk jugs and detergent bottles.

- Polypropylene (PP): A versatile plastic used in caps and closures due to its strength and high melting point.

- Polycarbonate (PC): Used for reusable water bottles and containers due to its toughness and transparency.

Each type of plastic has unique properties, chosen based on the intended use of the bottle. For example, how water bottles are made requires PET for its ability to preserve freshness, while HDPE is ideal for products like juices and milk. Understanding these materials is key to producing efficient, sustainable packaging solutions.

The Plastic Bottle Manufacturing Process

The production of plastic bottles involves several stages, each playing a vital role in shaping the final product. The manufacturing process is flexible, allowing for customization in size, color, and shape to meet specific product needs.

Step 1: Creating the Preform

- Raw plastic pellets (usually PET) are melted and injected into molds using injection molding machines to create preforms.

- These preforms, small and tube-like, serve as the starting point for bottle production.

- Many manufacturers purchase preforms instead of producing them in-house to save time and costs.

Step 2: Blow Molding

- Preforms are heated to a specific temperature, making them pliable.

- Using Bottle blowing machine, the preform is blown into a mold, forming the desired bottle shape.

- The mold determines the bottle’s size, design, and capacity.

Step 3: Cooling and Solidification

- The newly formed bottles are cooled to stabilize their structure.

- Cooling ensures the bottles maintain their intended shape and strength.

Step 4: Quality Inspection

- Each bottle undergoes rigorous inspection to identify defects like cracks, uneven shapes, or weak points.

- Bottles are tested for durability, resistance to pressure, and chemical safety.

Alternative Manufacturing Methods

Beyond standard blow molding, several other techniques are used depending on the type of bottle and material:

Extrusion Blow Molding

- Plastic pellets are melted and extruded into a tube-like form.

- Compressed air blows the molten plastic into a mold to shape the bottle.

- This method is ideal for producing HDPE bottles for milk, juice, and oil packaging.

Stretch Blow Molding

- Preforms are heated and stretched both axially and radially while being blown into the mold.

- This technique creates strong, lightweight bottles, particularly for carbonated drinks and water.

These alternative methods demonstrate how diverse the water bottle manufacturing process can be, catering to specific product requirements.

Quality Control and Inspection

Quality control ensures that plastic bottles meet the highest standards of safety and performance. Key aspects of this stage include:

- Defect Detection: Bottles are checked for cracks, uneven finishes, and other visible defects.

- Strength Testing: Bottles are tested to ensure they can withstand pressure, especially for carbonated drinks.

- Consistency Checks: Dimensions, weight, and capacity are verified to match specifications.

- Chemical Safety: Bottles are assessed for resistance to chemicals and suitability for food-grade use.

Factors Affecting the Bottle Production Process

Several factors influence the efficiency and outcome of plastic bottle production:

- Machine Efficiency: The type of machinery used, such as a Automatic bottle blowing machine or automatic plastic bottle making machine, directly impacts production speed, cost, and consistency.

- Material Quality: The quality of PET or HDPE resin determines the bottle’s strength, transparency, and recyclability.

- Energy Consumption: Choosing energy-efficient machines can significantly reduce operational costs while maintaining high output.

- Automation: Automated systems enhance precision, reduce labor costs, and allow for higher production volumes, making them indispensable for large-scale operations

Selecting the right equipment and materials is crucial for an optimized production process.

Common Challenges in Plastic Bottle Manufacturing

While the process is highly efficient, manufacturers face several challenges:

- Material Waste: Excess plastic generated during production must be minimized or recycled to reduce waste.

- Environmental Impact: Addressing concerns over plastic pollution is critical. Many manufacturers are investing in recycling initiatives and exploring biodegradable plastics.

- Machine Maintenance: Regular maintenance of blow molding machines ensures consistent product quality and prevents costly downtime.

Conclusion on Bottle Manufacturing

The production of plastic bottles is a highly sophisticated process involving advanced machinery and precise techniques. From selecting the right materials to ensuring top-quality manufacturing standards, each step is crucial for producing bottles that meet industry demands.

As manufacturers face increasing pressure to adopt sustainable practices, innovations like biodegradable plastics and energy-efficient machines will likely shape the future of plastic bottle production. For businesses seeking to optimize their production processes, investing in high-quality equipment like blow molding machines is key.

If you’re considering starting or optimizing a bottle production line, explore our newly released 3 in 1 blowing-filling-capping-combiblock machine designed for efficiency and precision. Contact us today for more information!

]]>