China’s reputation for innovation and affordability makes it a preferred manufacturer for businesses worldwide. They are the go-to source for affordable and reliable plastic extruders. In this post, we will learn why, what machinery is available, and how to choose a contract manufacturer plastic parts provider like Faygoplas for your business needs. Let’s get started!

1) What is the Reason Behind China’s Popularity for Plastic Extruders?

China’s plastic extruder manufacturing industries provide rapid refinement of machinery while keeping costs low. Whether launching a new product or scaling business operations, China’s extrusions provide unmatched performance and value.

- Advanced Manufacturing at Lower Costs

China’s plastic industry factories offer powerful machines and equipment at a lower cost compared to the US and Europe. Their use of sophisticated supply chains and mass production makes them offer unrivalled value for their equipment.

- Innovation Backed by R&D

Leadership in various machinery co ltd sectors improves the China plastic extruder design, like screw design, smart controls, and heater efficiency. It is all done by working with universities, funded research labs, and tech.

- Scope and Flexibility

China has it all, from lab scale to industrial extruders, even to sheets, pipes, and films, including biodegradable options. Moreover, machines can be tailored for your specific application, from screw diameter to output rate and even system size.

- Reputation and Readiness for Exports

Ensured quality providers have CE, UL, and ISO compliance. Another good thing is that reliable suppliers are familiar with shipping, handling, and serving documentation and certification demands for international clientele.

- Immediate Client Servicing and shipping

Staff who speak English, combined with virtual site visits and expedited shipping, mean timely servicing and seamless interaction. Contact and parts are delivered and replenished in days.

- Case In Point

- A Brazilian company implemented a Chinese PET sheet production line for food packaging in 27 days.

- An Indian company that had just started took on a Chinese PLA film extruder to produce compostable bags.

2) Kinds of Plastic Extruders You Can Source from China

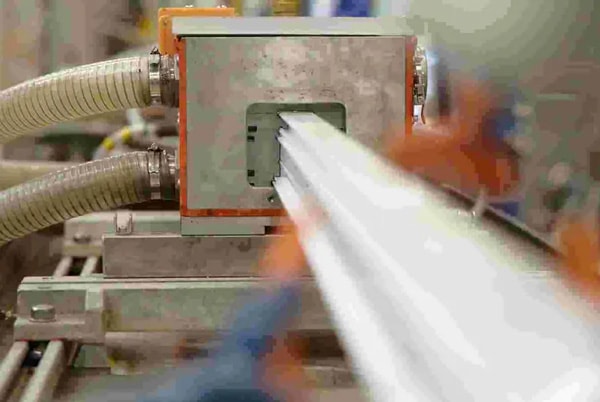

China’s extrusion plastic industry has a wealth of machines to meet various types of production requirements. Single screw extruders, custom single screw extruders, and twin screw extruders are the most common ones. Here’s a comparison between the two.

i) Twin Screw Extruders

Complex tasks requiring extensive processing, as well as output and blending of the material, are best served with twin screw extruders. Chinese manufacturers have refined these machines to handle applications such as:

- Plastic granulation with additives or color masterbatch

- Producing multi-layered films and sheets

- Pipe and profile extrusion

- Biodegradable and other specialty blends

- Why choose them?

Their performance in mixing and blending various materials is unmatched, along with high melt quality. Chinese twin-screw extruders with a torque rating of 14 Nm/cm³ and speeds of 1800 RPM offer unrivalled performance.

ii) Custom Single Screw Extruders

Single screw extruders are less complicated and more suited for simpler projects with minimal mixing requirements. Chinese suppliers offer custom designs tailored to your desired material, output, and budget. Their applications include:

- Cable sheathing

- Small-diameter tubing

- Basic profiles and 3D printing filament

- Why choose them?

They are more affordable, have low operational and maintenance demands, and are best for low to mid-volume production.

Which Should You Choose?

- Opt for twin screw extruders if you’re dealing with multi-component materials or require high throughput.

- A single screw is ideal if your focus is on simple thermoplastics and if you prefer less complexity during setup.

You can fully customise your machine on whichever model you prefer with China’s vast sourcing capabilities.

3) Specialized Plastic Extrusion Lines

China is not just a supplier for general-purpose extruders, but is also a provider for industry-specific turnkey project extrusion lines designed with precision for performance, quality, and speed. Here are some solutions from top Chinese sellers:

a) PPR Pipe Production

These machines manufacture 3-layer PPR pipes with a fibreglass middle layer that enhances the strength and thermal resistance of the pipes. Their dust-free cutting systems provide seamless edges that minimise the need for post-processing, making them ideal for plumbing and heating systems.

b) Dip Tube Manufacturing

Dip tubes are used in spray and pump bottles. Chinese dip tube extruders work with thermoplastic elastomers and feature angle cuts to avoid leakage and blockage.

c) PVC Braided Hose Lines

These PVC extruder lines possess high tenacity polyester yarn-embedded inner and outer PVC layers. This results in a flexible and strong hose used in construction and appliances, and in gardening. Bonding excels in enhancing integrity and clarity.

d) Multi-Color Shower Hose Extrusion

These lines produce multi-colour glossy shower hoses for sanitary products employing heat-transfer coating and EU-compliant colour sheets for an appealing and safe finish.

e) PC/PMMA Profiles for LED Covers

These extruders develop optical-grade LED profiles for lighting. Co-extrusion latest technology, permits amalgamating PC and PMMA for UV resistance, clarity, and structural integrity.

f) TPE Elastic Strip Extrusion

These lines produce strips used in packaging, seals, and wearable technology. Thicker uniform strips are achieved with calibrated cooling rollers, tight thickness control, and flexibility.

Most of these extrusion lines are modular units and turnkey systems, designed to fit the client’s requirements.

4) Advancements in Technology and Smart Control

With the aid of global supply chains and innovation programs, China’s plastic extrusion machine industry is successfully competing with European companies in several critical areas due to its extensive experience. Now, Chinese manufacturers can produce extruders that are on par with European systems.

Modular Configuration of Chinese Extruders

Today’s Chinese Extruding Machinery co ltd is modular, enabling users to select feeder systems and die heads, screws, and barrels of varying lengths. This drastically lowers the chances of underperformance during production and expedites development time.

In addition, many of the essential parts that are important for reliability, such as control systems, motors, and even gearboxes, are integrated from top international manufacturers.

Smart Control Systems

No doubt, the evolution of artificial intelligence is occurring at a rapid pace. A number of Chinese equipment now includes smart features such as real-time fault monitoring, automated process supervision, and smart temperature regulators. These functions enhance stability, lessen manual mistakes, and minimise waste. Even some systems are capable of cloud-based remote diagnostics, too.

Alright, China now serves as more than just a cost-effective manufacturing option, as the country has become an innovation centre. Chinese extruders are positioned as forward-looking options for manufacturers who need smart technology, adaptability, and operational performance.

5) How Faygo Union Supports Your Plastic Extrusion Projects

It is essential to assess your design, material, and process validation before you are fully committed to a complete extrusion line. This is where Faygoplas can strategically help you. We are among the foremost rapid prototyping and low-volume manufacturing firms established in China, with extensive experience.

We help as a backbone in the transition from concept to production, which helps manufacturers scale up with certainty.

- Rapid Prototyping for Dies and Parts

Faygoplas helps in testing new extrusion shapes and custom profiles with remarkable precision to prototype the dies with the aid of CNC machining and 3D printing for nozzles, fittings, and end-use components. This helps you assess how the plastic will act in real-world plastic extrusion scenarios prior to any tooling expenditure.

- Design and short-run Faygoplas feedback sessions

At Faygoplas, we always make an effort to delve deeper than simply building what you send us. Well, every submission undergoes CAD file inspection to uncover potential weak points, material flow issues, and overall, any concerning tolerances.

To make it better, you get feedback and suggestions from seasoned engineers experienced with various industries and extrusion setups, allowing you to sidestep costly blunders.

- Short-run Production for Feasibility Testing

Do you need to test a product for market acceptance, product durability, or any other test? At Faygoplas, our mission includes conducting small batch productions that allow you to test products along their full life cycles. You can also replicate extrusion behaviour to work on packaging, fit, or function without running an entire production line.

- Minimising Investment Risk, Faygoplas Approach

With us, there’s no lasting investment to be made in custom extruders or permanent molds. We take an iterative method by allowing you to refine, improve, and test your extrusion concept. This is a great option for startups, R and D departments, along with any product teams looking to test new formulations or designs.

- Real Customer Experiences

Good to share that clients who worked with professional Chinese plastic Extruder firms have cited the use of their machines for decades, along with their customer service. Clients emphasised that the high service responsiveness, low downtimes, and stable output quality all contributed to the enduring use of the machines.

Others praise the speed of contact response and replacement part sales. Faygoplas’s employees are often credited for offering feedback that reduced errors in early-stage granulation and product validation.

Conclusion

China, in particular the Jiangsu province and Zhejiang provinces, is the largest producer of plastic extruders in the world. Their manufacturers are well-equipped, at industry-competitive pricing, and leverage modern technology.

With trusted suppliers and industry leaders like Faygoplas, China’s plastic industry advantages are ready to be explored, assuring that you’re supported throughout the manufacturing process. You can contact us right now!