Extruded plastic profiles are crucial components created by transforming raw plastic into continuous shapes. Widely used in automotive, medical, and construction sectors, these profiles enhance functionality and efficiency. This article explores their manufacturing process and diverse applications.

Key Takeaways

- Extruded plastic profiles are vital in various industries such as automotive, medical, and construction, providing functionality and design versatility.

- Customization in plastic extrusion allows for tailored profiles that meet specific industry requirements, enhancing functionality and precision.

- The plastic extrusion process involves careful quality control and monitoring to ensure optimal performance, durability, and compliance with industry standards.

Overview of Extruded Plastic Profiles

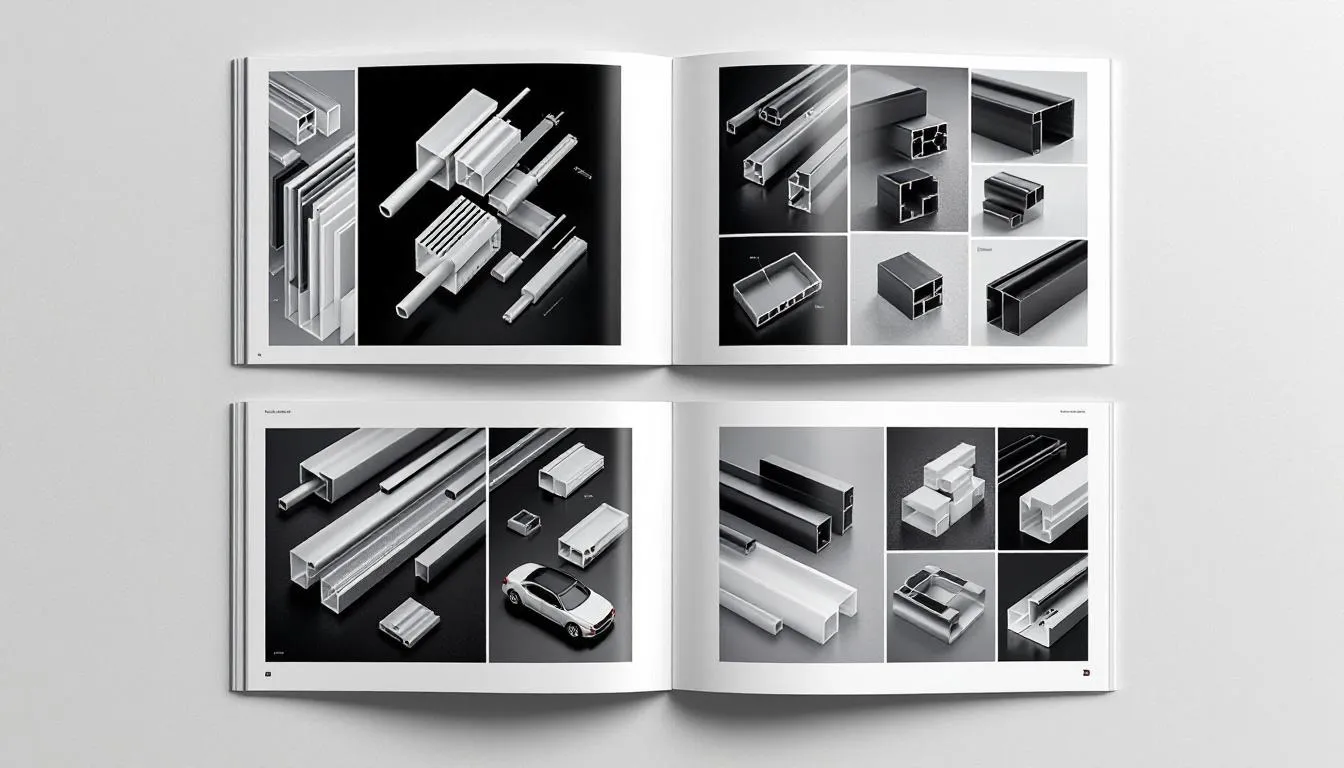

Plastic extrusion is a high-volume manufacturing process that transforms raw plastic materials into continuous profiles, known as extruded plastic profiles and stock plastic extrusions. These profiles are indispensable in various industries, contributing significantly to manufacturing efficiency and versatility. From automotive parts to consumer goods, extruded plastic profiles are everywhere, enhancing both functionality and design.

The versatility of extruded plastic profiles is evident in their usage across diverse sectors:

- In the automotive industry, they are used for weather seals and interior trims.

- In the medical field, they form the backbone of tubing and catheters.

- Agricultural applications, consumer goods, and even solar panels benefit from the adaptability and durability of extruded plastic profiles.

The process allows for the manufacture of tailored shapes and manufactured components, ensuring that each profile meets specific industry requirements.

Common shapes of plastic profiles include:

- Thin films

- Rods

- Wire sheets

- Trims

- Channels

- Tubing

- Gaskets

These shapes are designed to meet the unique demands of their respective applications, providing durability, flexibility, and efficiency. Materials like polyacetal, acrylic, and nylon further expand the range of applications, making polymer plastic extrusion a versatile and invaluable process in modern manufacturing.

Types of Plastic Materials Used in Extrusion

The choice of plastic materials is crucial in plastic extrusion, as it determines the properties and applications of the final product. A variety of thermoplastic materials are utilized, including ABS, PVC, and polypropylene, each offering unique plastic material properties that cater to specific needs, including different viscous plastics. For instance, material selection is important, as PVC is known for its durability and resistance to environmental factors, making it ideal for construction and automotive applications.

Polyethylene, polypropylene, polyacetal, acrylic, nylon, polystyrene, ABS, polycarbonate, and acrylonitrile butadiene styrene are among the most commonly used materials in plastic extrusion. Each material brings its own set of advantages:

- Low density polyethylene: valued for its flexibility and resistance to chemicals.

- Polypropylene: offers high tensile strength and is used in a variety of industrial applications.

- Polycarbonate: known for its impact resistance and is often used in safety and electronic applications.

Bausano extruders, for instance, can process a wide range of materials, including PVC and HDPE, enhancing the possibilities for custom plastic extrusions. This capability allows manufacturers to select the best material for their specific application, ensuring optimal performance and durability.

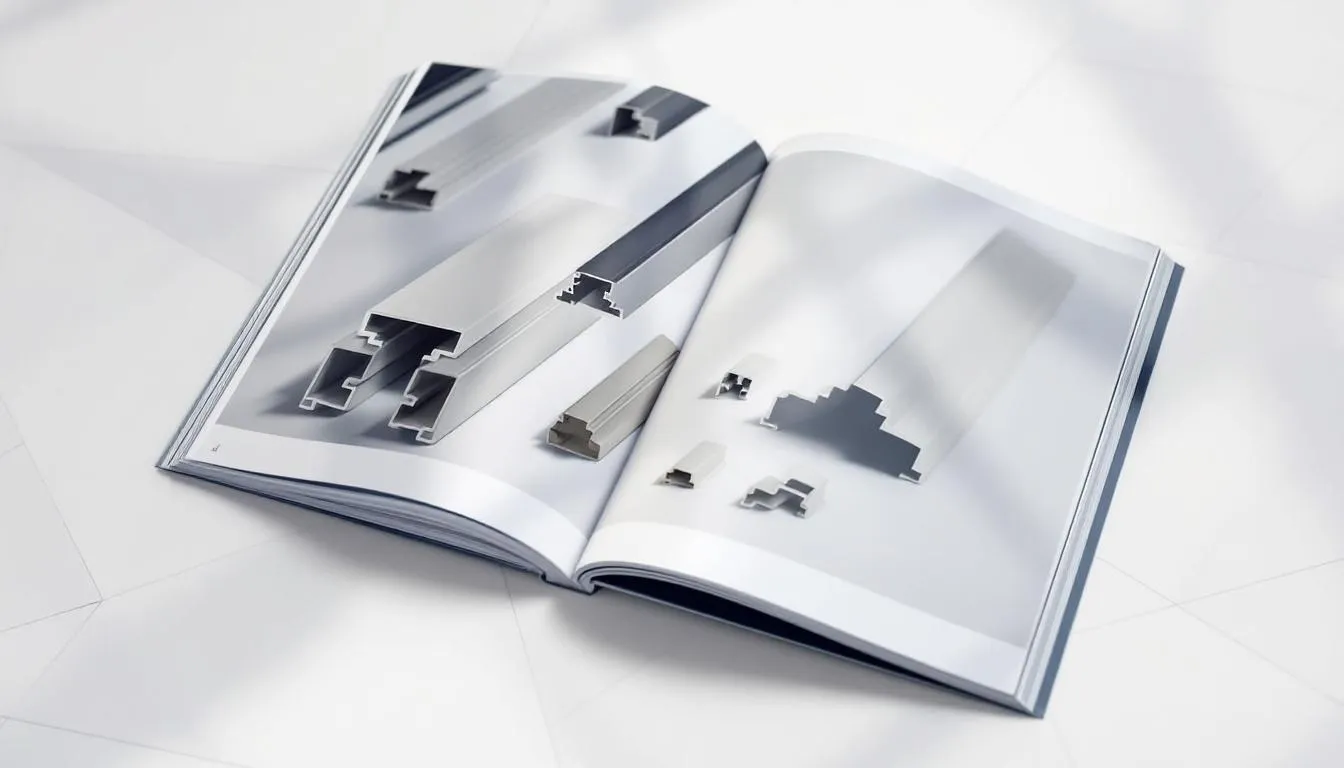

Custom Plastic Extrusions

Customization in plastic extrusion is a game-changer, allowing manufacturers to design unique profiles that meet specific industry requirements. This capability is especially crucial for projects that demand tailored solutions. Whether it’s a complex automotive component or a specialized medical device, custom plastic extrusions can be meticulously designed to enhance functionality and fit precise application needs.

The ability to produce small, tailored batches efficiently has significantly improved with advancements in customization capabilities. This means that even niche applications can benefit from the precision and versatility of custom plastic extrusions. Options for additive customization, such as UV resistance, color matching, and flame retardance, further enhance the performance of these profiles in various environments.

Precision manufacturing is key in custom plastic extrusions. Tolerances for wall thicknesses can range from 0.030 inches to 0.375 inches, ensuring that each profile meets the exact specifications required for its application. This high degree of customization in shapes and sizes makes extruded plastic profiles indispensable for a wide range of industries.

The Plastic Extrusion Process

Plastic extrusion is a high-volume manufacturing process that transforms raw plastic materials into continuous profiles. The processed materials involve:

- Starting with raw plastic materials, typically in the form of granules, plastic pellets, pellet form, or powder.

- Feeding these materials into a heated chamber.

- Using a rotating screw to move the materials through the chamber.

- Gradually melting the materials through friction and applied heat in the plastics extrusion process.

The extrusion process involves the following steps:

- The temperature applied is carefully tailored to the specific type of plastic being used.

- As the plastic moves through the screw conveyor, it is sheared and heated, eventually becoming molten plastic.

- This molten plastic is then forced through a die, which shapes it into the desired profile extrusion by extruding it.

- The design of the die is crucial, as it ensures a smooth and consistent flow of melted plastic into the final product shape.

Cooling is an essential part of the extrusion process. Once the plastic exits the die, it must be cooled quickly to retain its shape. This can be done using air or water as the extruded plastic moves onto a conveyor belt. Cooling rolls may also be used to cool and size the extruded plastic immediately, ensuring precise internal and external dimensions.

Quality control is integral to the plastic extrusion process. It involves:

- Assessment of raw plastic materials to ensure their purity and integrity.

- Regular inspection of the extrusion die and screw to maintain proper material flow and pressure.

- Monitoring temperature, pressure, and speed during the extrusion process to guarantee consistent product quality.

Applications of Extruded Plastic Profiles

Extruded plastic profiles are used in a wide range of applications, thanks to their versatility and functionality. In the construction industry, extruded profiles contribute to the creation of weather-resistant and thermally efficient profiles used in windows and doors. These profiles help improve energy efficiency and durability in buildings, making them an essential component in modern construction.

The automotive industry relies heavily on extruded plastic profiles for various parts, especially those such as weather seals and interior trims. These other components are designed to withstand chemical and temperature variations, ensuring long-lasting performance.

In the medical field, plastic extrusion is key for producing rigid tubing and catheters, utilizing medical-grade plastics that comply with regulatory standards.

Extruded plastics also play a significant role in the packaging industry, where they are used to create plastic film and sheets of various thicknesses. These materials offer protective qualities that enhance product shelf life. Additionally, materials like polycarbonate and polystyrene are used in specialized applications, such as electronic housings and solar panel frames, further showcasing the versatility of extruded plastic profiles.

Advantages of Using Extruded Plastic Profiles

The advantages of using extruded plastic profiles are numerous. Their lightweight nature simplifies handling, transportation, and installation, leading to significant cost savings. Additionally, extrusion tooling is generally more economical and efficient compared to other plastic manufacturing methods.

Plastic extrusions are also known for their resistance to corrosion, chemicals, and moisture, making them suitable for harsh environments. The fabrication process is straightforward, allowing for efficient cutting, drilling, and assembly. Twin screw extruders, in particular, offer enhanced efficiency and energy-saving benefits, especially when handling materials with poor thermal stability.

Twin Screw Extruders vs. Single Screw Extruders

Twin screw extruders and single screw extruders each have their unique advantages and applications. The most common type of twin screw extruders are divided into two main types. These are co-rotating and counter-rotating extruders. They excel in blending and reactive extrusion due to their advanced mixing capabilities. Moreover, twin screw extruders have superior venting and self-cleaning functions compared to their single screw counterparts.

Single screw extruders, on the other hand, are simpler and less costly, making them suitable for basic applications. The E-GO Series one screw extruders, for example, are customizable in every detail with Digital Extruder Control 4.0, providing precision and efficiency for various plastic extrusion needs, including individual extruders delivering and a single extrusion head.

Co-extrusion Techniques

Co-extrusion is a technique that allows for the combination of multiple materials or colors in a single extrusion, providing both structural and aesthetic benefits. This method enables the fusion and layering of multiple layers to create a composite structure with enhanced properties. For instance, using different materials in co-extrusion can yield products with improved stiffness and resistance to heat.

However, co-extrusion also comes with its challenges. Not all plastics can be co-extruded due to compatibility issues, particularly with polymers that have differing melting points. Despite these challenges, plastic co extrusion remains a valuable technique for producing multilayer films or packaging that enhance product durability and strength.

Quality Assurance in Plastic Extrusion

Quality assurance is paramount in plastic extrusion to ensure that the final products meet desired technical and functional standards. Adhering to industry standards, such as ISO certifications, enhances the reliability and durability of extruded plastic profiles. Bausano, for instance, ensures maximum quality at the technical-functional level during the plastic extrusion process.

These quality control measures contribute to the overall excellence and durability of extruded plastic profiles. Monitoring parameters like temperature, pressure, and speed during the extrusion process ensures consistent product quality and performance.

Choosing the Right Plastic Extruder Manufacturer

Selecting the right plastic extruder manufacturer is crucial for ensuring high-quality production. A strong track record in the plastic extrusion industry is a key indicator of a manufacturer’s reliability. Evaluating the technology and equipment used by a manufacturer can significantly impact production precision and efficiency.

Good communication and after-sales support are essential for building a trustworthy supplier relationship. Customer feedback and references provide valuable insights into a supplier’s reliability and service quality. Additionally, on-time delivery performance is crucial for maintaining production schedules and avoiding disruptions.

Innovations in Plastic Extrusion Technology

The plastic extrusion industry is witnessing significant advancements, particularly with the integration of digital technologies. These innovations allow for real-time monitoring and predictive maintenance, enhancing efficiency and reducing downtime. Energy-efficient designs and advanced heating systems are being developed to reduce energy consumption in plastic extrusion processes, including those involving plastic extruders. The plastics industry is evolving rapidly, adapting to these new technologies.

Incorporating renewable energy sources is another innovative solutions practice being adopted to decrease reliance on fossil fuels. These developments are essential for lowering carbon emissions and promoting sustainability in plastic extrusion manufacturing.

Environmental Impact and Sustainability

The environmental impact of plastic extrusion processes is a significant consideration, given the materials used and energy consumed. Key points include:

- Utilizing recycled materials in extrusion processes can significantly reduce environmental impact.

- Co-extrusion techniques can incorporate recycled materials mixed with virgin plastics.

- These methods help reduce material costs and waste.

The plastic extrusion industry is increasingly moving towards a circular economy model by incorporating recycling technologies to minimize the need for new materials. Recent technological advancements, such as induction heating systems and recycling extruders, have enhanced sustainability in plastic extrusion.

Manufacturers are committed to reducing energy consumption and recovering plastic scrap material to lessen their environmental impact.

Summary

In summary, extruded plastic profiles are a cornerstone of modern manufacturing, offering versatility, efficiency, and customization. The high-volume manufacturing process, coupled with the wide range of materials available, makes plastic extrusion an invaluable technology across numerous industries. From construction to automotive, and medical to packaging, the applications are diverse and impactful.

As we move forward, innovations in plastic extrusion technology and a focus on sustainability will continue to shape the industry. By understanding the intricacies of the extrusion process and the benefits of custom plastic extrusions, manufacturers can leverage this technology to enhance their products and reduce their environmental footprint. The future of plastic extrusion is bright, promising continued advancements and sustainable practices.