Are you finding it challenging to efficiently and economically manufacture quality plastic components for your project? It could be that the plastic extrusion process is all you need for your project. It is a process that allows the transformation of raw plastic materials into tailored shapes like pipes, films, and others.

Let’s have a look at its workings and the reason it is the process of choice for leading manufacturers. Stay connected!

1) What is Plastic Extrusion?

Plastic extrusion is a continuous process and a high-volume process that is performed to manufacture long plastic products, which are uniform in shape and have a constant cross-section. The process begins by putting raw thermoplastics in pellet or granule form into an extruder.

The raw thermoplastics are then subjected to heating, pressure, and conveying through a shaped die to be “extruded” to form a profile. The plastic is cooled and solidified rapidly as it is dying, thus achieving plastic products that are finished and ready for use or further processing.

Well, this technique is particularly useful in fields that need strong yet light and intricately shaped plastic parts. Due to its continuous extrusion process, this technique of plastic extrusion can produce uninterrupted long lengths of products, which is especially helpful in mass production.

You know uniformity and quality in products are essential in many cases, and plastic extrusion is the best option for such situations, as it provides extreme control over the quality and the thickness of the surfaces, as well as finishes.

2) Key Components of a Plastic Extruder

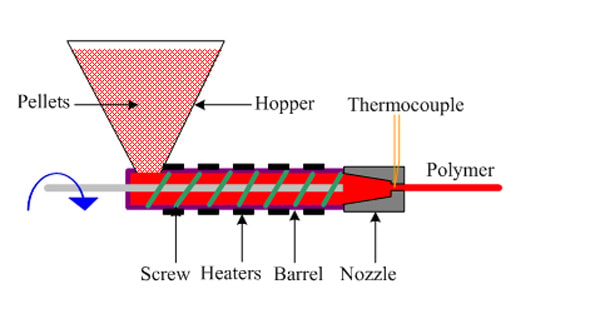

A plastic extruder is made of a number of basic parts, each performing an operation in sequence, which transforms raw plastic into a finished article. Below are the main components:

a) Hopper: This marks the beginning of the process as plastic pellets or granules are loaded. It uses gravity to feed the material into the extruder.

b) Feed Throat: Connects the hopper to the barrel and ensures a steady flow of material as well as an exit for any gases or air pockets before melting.

c) Barrel and Screw: This is the section where the plastic is simultaneously mixed and melted. As the screw rotates, it moves the material to the forward section of the heated barrel, assuring smooth and uniform melt.

d) Die Assembly: The molten material is pushed to a metal die where it is shaped into the final product, which includes tubes, sheets and films.

e) Cooling System: Once the plastic has been shaped, it can be transported to the cooling section, which includes water baths, cooling rolls or air cooling. This step helps to solidify the plastic and ensures its shape can be retained.

3) How Does Plastic Extrusion Work?

Plastic extrusion is a sequential process that converts raw plastic materials to shape them to a desired final shape. Each raw plastic needs to be melted to shape it, and the process should be well controlled in the crystallising and finishing stages.

a) Process Steps

- Feeding (Hopper to Feed Throat): The first step of the process is to feed the plastic beads forward into a hopper via a breaker plate. This step is important as it ensures that the plastic beads forward are appropriately and consistently gravity fed to the feed throat. From this section, the materials are transferred to the heated barrel.

- Melting (Screw Rotation and Heat Zones): The screw in the barrel spins, and the plastic in the barrel is moved towards the front. While the plastic is moved towards the front, it gets external heating as well as heat due to the friction caused by the screw.

The external heaters and the friction caused screw ensure that the plastic is brought to the required melt temperature. This ensures that any plastic in the barrel is melted into a uniform and flowable mass.

- Shaping (Extrusion Die): To form the desired shape of the product, a specific die is used. The molten plastic is forced through the die to achieve the desired shape of a cross-section of a pipe, sheet, or film.

- Cooling (Water, Air, or Rollers): The goal of any plastic manufacturer is to preserve the overall shape of the product. After the product has been moulded, various cooling techniques can be used to preserve the molten plastic shape. These methods include water baths or air and roller cooling.

- Post Processing (Cutting, Printing, Annealing): Plastics that have been cooled after extrusion can be additionally processed, such as cutting to size, printing on, or applying surface treatments. The product may also be annealed to reduce internal stress, yielding a more durable output.

b) Screw Extrusion Zones Explained

- Feed Zone: The goal is to eliminate air pockets and guarantee smooth feeding as the screw has a constant flight depth. During the process, the raw materials are heated.

- Transition (Compression) Zone: As the screw channel becomes shallower, the material in the channel is compressed and begins the melting process as a result of the heat and pressure.

- Mixing Zone: In this section, the flight depth is constant. To achieve a uniform temperature and material blend throughout, screw elements are used to thoroughly blend the molten plastic.

- Metering Zone: In the metering zone, the pressure is increased to push the homogeneous melt over the die. The flight depth continues to maintain a steady depth, which promotes consistency in flow and quality of the product.

All of these steps, along with the screw zones, increase dependability in the process of plastic extrusion, making it an effective approach to high volume manufacturing process plastic components of superior quality.

4) Types of Plastic Extruders

Different models of plastic extruders are categorised as single screw, twin screw, or specialised extruders, each with different applications.

- Single Screw Plastic Extruders

Single screw extrusion machines are the most utilised, as they contain a rotating screw (The radial clearance relative to the screw diameter typically ranges from 0.0005 to 0.0020, with an average ratio of 0.001) encased in a heating barrel.

Single screw extruders are best for simple shapes like pipes and sheets. Although they are cost-effective, single screw extruders are not as good at mixing and can be inefficient in advanced applications.

- Twin Screw Extruders

Twin screw extrusion machines are used for more advanced applications as they contain two rotating screws. These plastic extrusion machines are more costly and can be complicated to operate, but provide better mixing and more control over temperature and pressure.

Generally speaking, twin screw extruders are especially good with additives, fillers, and reinforcements.

- Specialty Extruders

Some extruders are made for specific industries with more complicated extruding needs. Speciality extruders such as roller extruders need more control over heat and viscosity, and are used in the medical and electronics industries.

5) Common Plastic Extrusion Processes

Depending on the product to be manufactured in the plastic industry, apart from injection molding, plastic extrusion can be adapted into several processes. Each method serves certain industrial purposes:

i) Tubing Extrusion: This is applied in the production of hollow materials such as pipes, straws, and tubes. A mandrel is placed in the die to keep the hollow shape, and the plastic tubing is cooled in a water tank for solidification.

ii) Blow Film Extrusion: This is the method to use for the production of plastic bags and packaging films. A bubble of plastic is blown and later on flattened and wound on rolls. Moreover, this ensures that the thickness and width of the films are maintained.

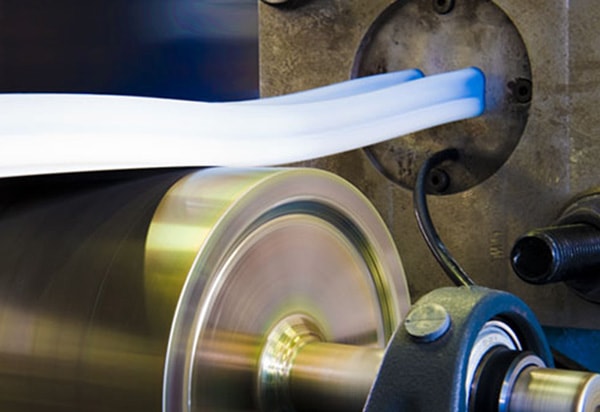

iii) Sheet Film Extrusion: Used in the creation of thick plastic sheets for packaging, construction, and thermoforming. The thick plastic melt is extruded through a flat die and cooled on rollers to maintain the thickness as well as the smooth surface of the product.

iv) Over-Jacketing Extrusion: It is best for electrical purposes and specifically for insulating wires and cables. And, it is where a molten plastic layer is injected on the wire for electrical and physical protection.

6) Industrial Applications of Plastic Extrusion

- Construction Industry: Alongside strength, water resistance, and durability, these materials provide a long lifespan, which helps in the creation of pipes, window frames, door seals, and wall panels.

- Packaging Industry: Manufactures films, wraps, and sheets used for packaging food, medical supplies, and other consumer products that require specific thickness and flexibility.

- Automotive Industry: With its low weight and inexpensive cost, it is utilised in the production of bumpers, dashboards, and trim, as well as gaskets and cable covers.

- Electrical & Electronics: Used to insulate wires and other electric cables, construct tubing for wiring harnesses, and form protective enclosures for various electric parts.

- Medical Sector: In the case of the medical sector, the plastic materials are processed by sheet extrusion to make tubing, catheters, and protective coverings, which need to be sterile and made with great accuracy.

- Consumer Sector: These sectors also make use of extrusion processes to manufacture plastic furniture edging, curtain rails, toys, containers and other household items with custom shapes and a polished outer layer.

- Agriculture: In agriculture, it is used to manufacture plastic films for use in greenhouses, irrigation tubing, and protective crop covers, which are resistant to ultraviolet rays and weather.

- Retail and Display: These include the sign holders, shelf strips, display rails and parts of the package which are used for the products.

7) Conclusion

From the information provided, it can be seen that the extrusion of plastic parts can be used in different industries. It is also proven that the processes of producing different parts by extrusion are efficient in both time and cost.

For precision and efficiency in plastic extrusion equipment processes, Faygo Union is the recommended manufacturer. We offer plastic extrusion services in a well-managed manner. Moreover, we try our best to deliver your order within 3 business days. You can get in touch with Faygoplas right now!