Key Takeaways

- Plastic extrusion is a precise manufacturing process that transforms thermoplastic materials into various shapes through heating, melting, and cooling.

- Understanding the types of extruders—single screw and twin screw—is crucial for selecting appropriate equipment for specific applications, with each type offering distinct advantages.

- Custom and co-extrusion techniques allow for the production of tailored plastic profiles and multi-layered structures, enhancing product performance and meeting diverse industry needs.

Understanding Plastic Extrusion

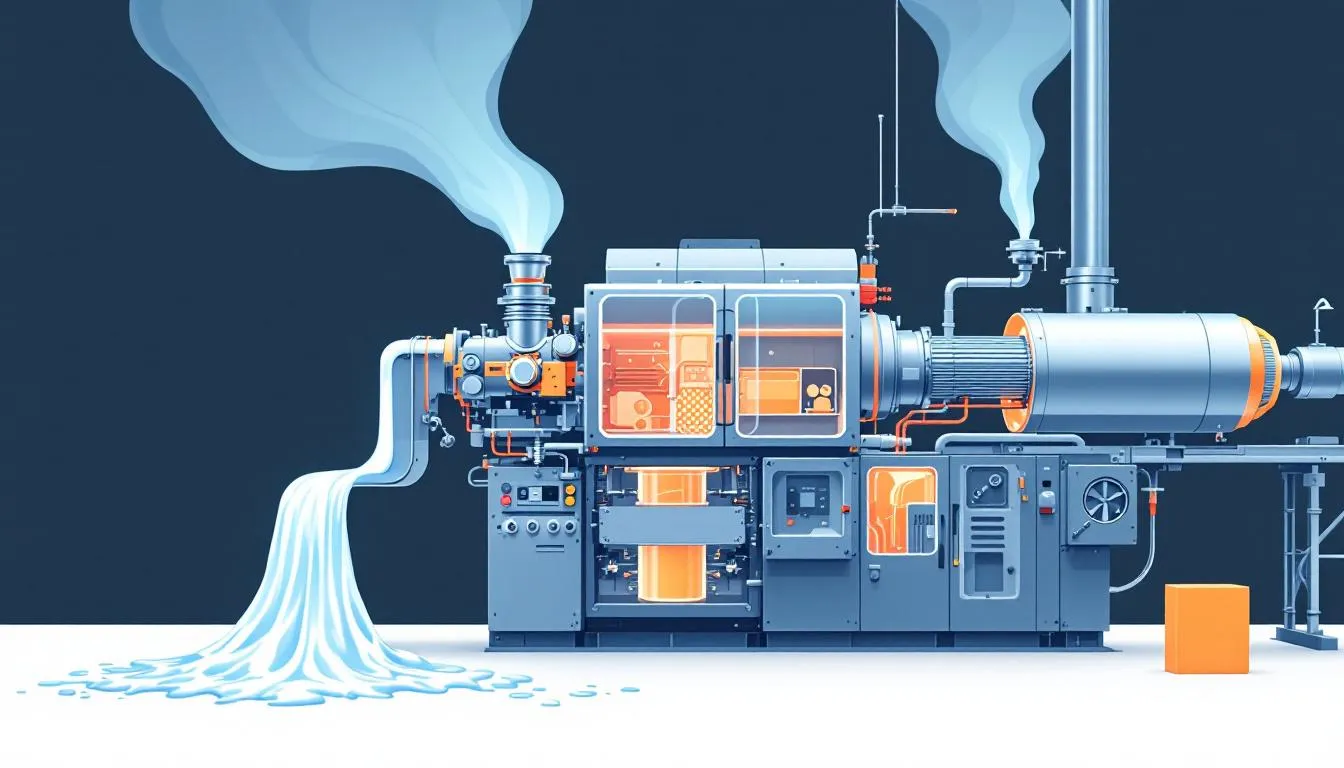

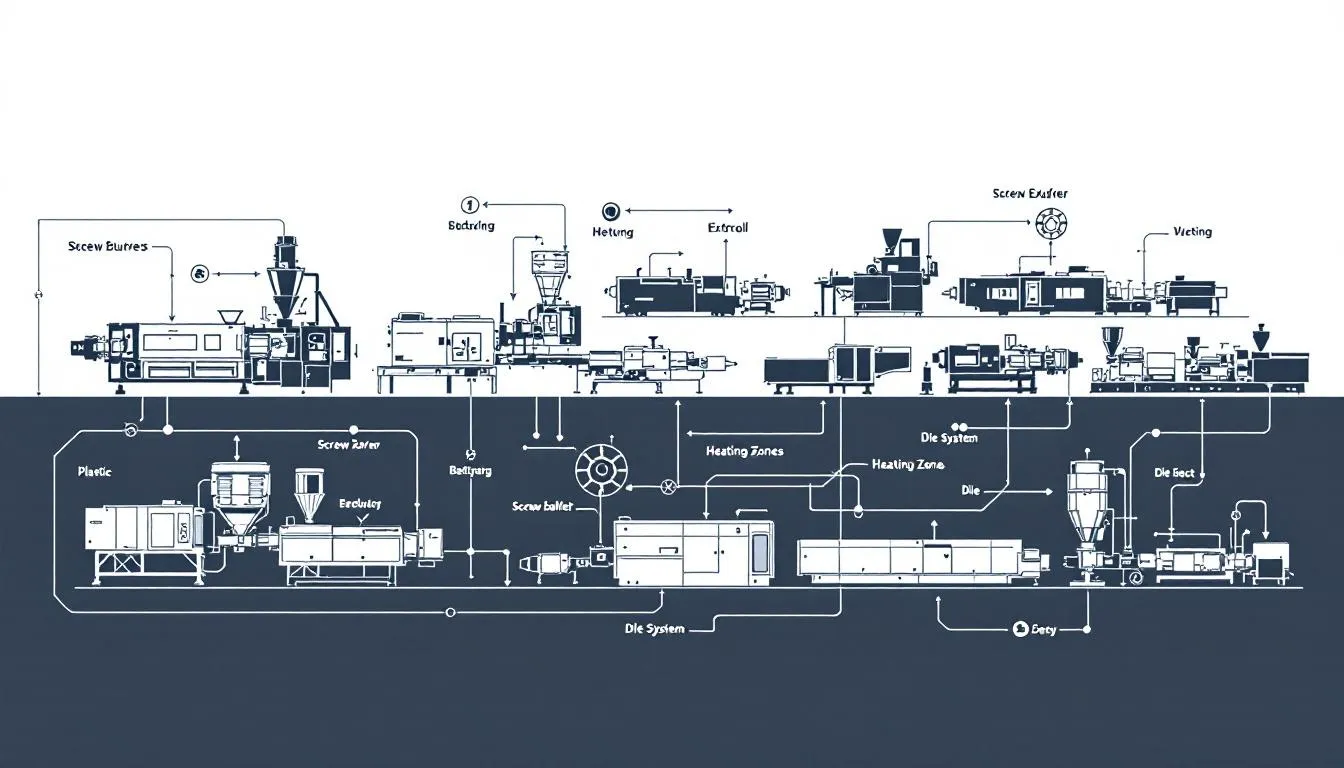

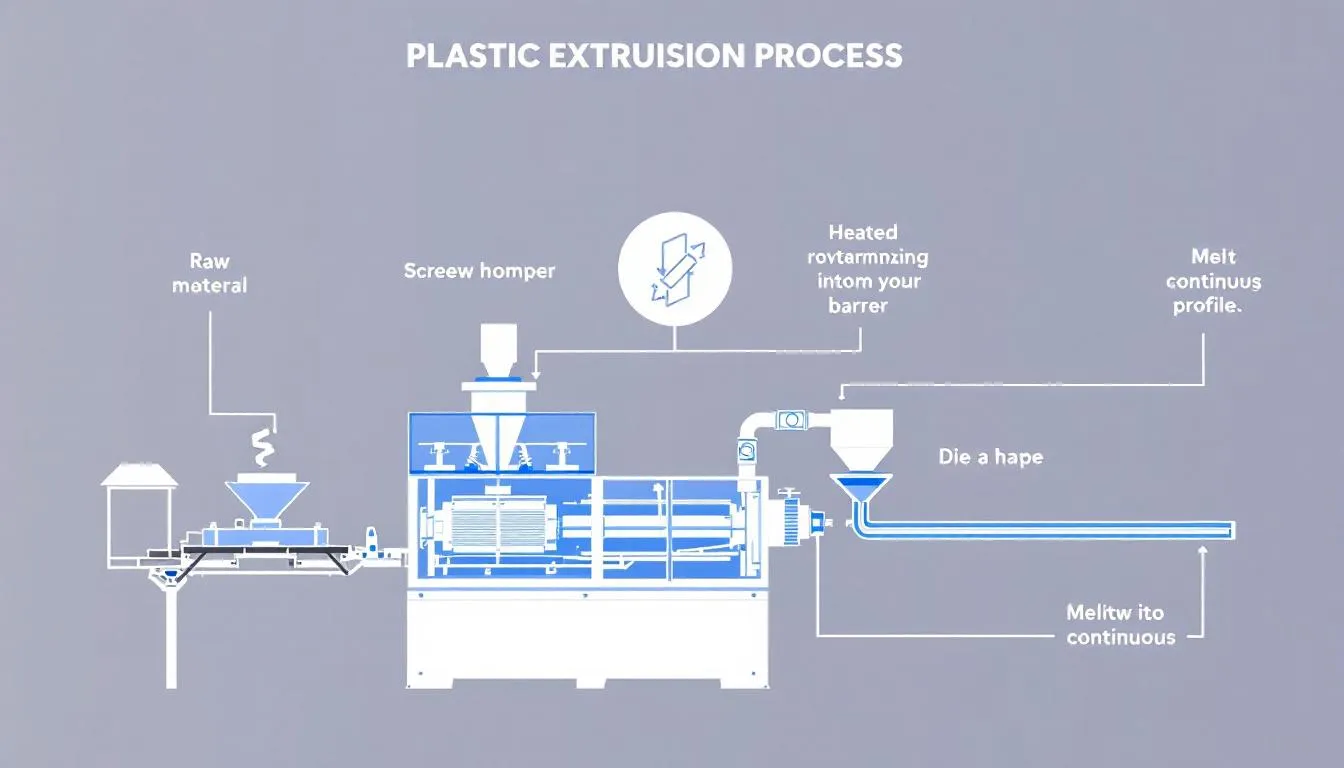

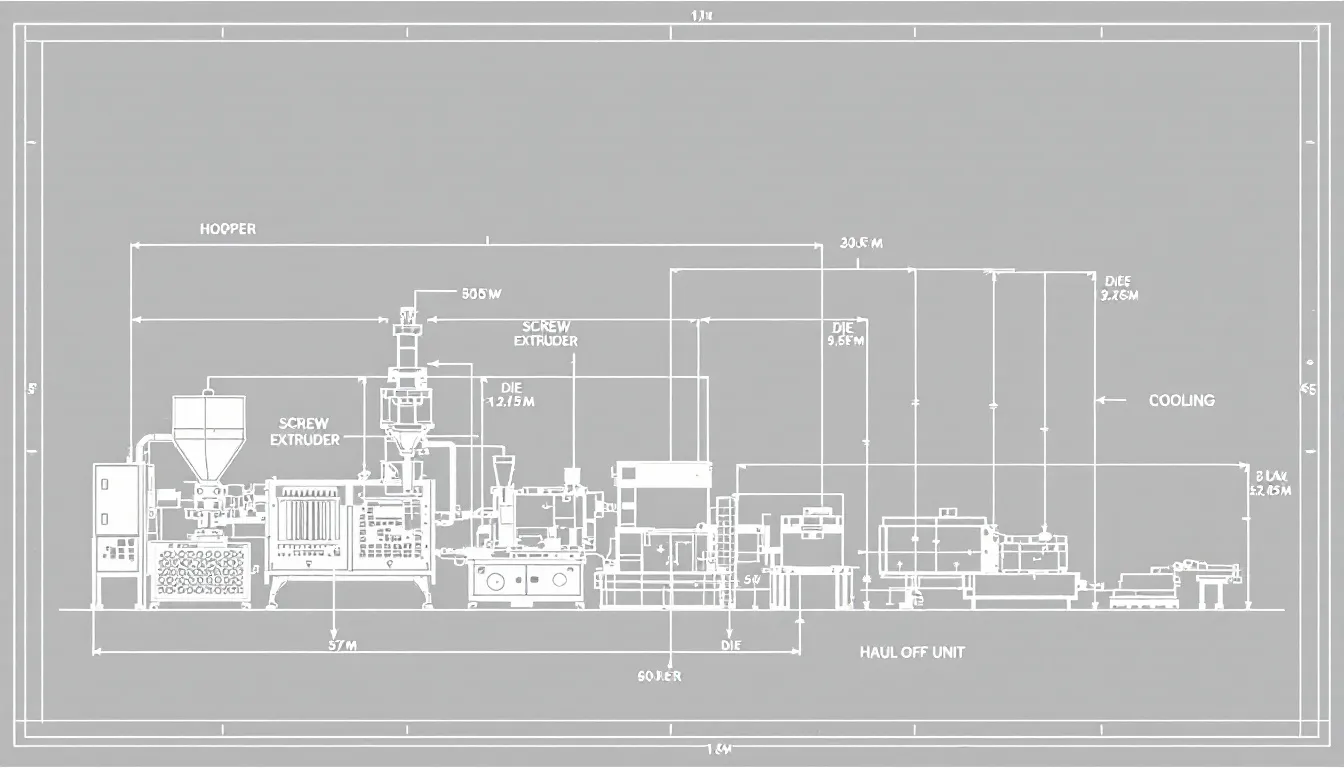

Plastic extrusion is a method where thermoplastic material is melted into a homogeneous state before being shaped through a die. The process involves the following steps:

- Feeding raw plastic material from a hopper into the barrel.

- Inside the barrel, a rotating screw applies pressure, pushing the molten plastic through a precisely shaped die, which determines the final profile of the extruded product.

- Cooling the extruded material to retain its newly formed shape.

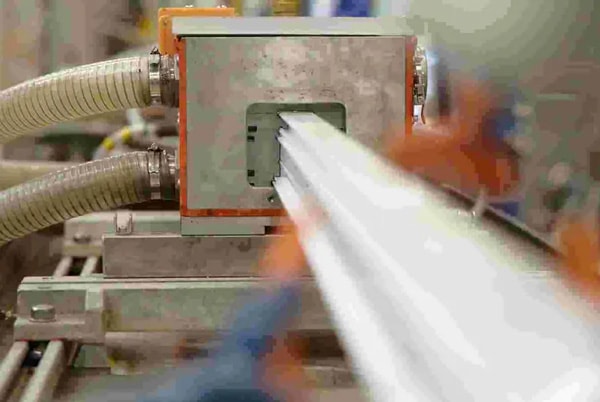

Picture a bustling factory floor where the plastic extrusion process is in full swing:

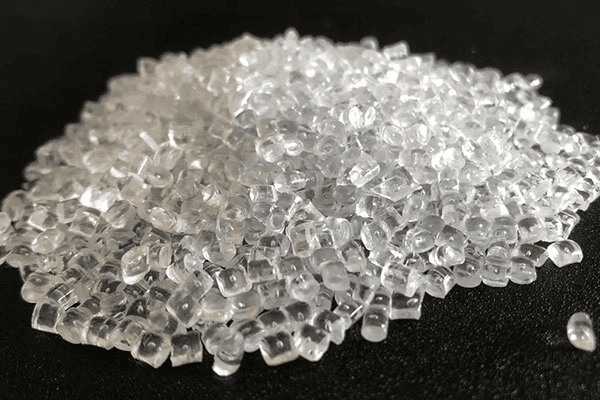

- Raw plastic granules are fed from a hopper into the barrel.

- The granules are heated and transformed into a molten polymer.

- The rotating screw applies just the right amount of pressure to push the molten plastic through the die.

- The extruded plastic profiles emerge and are quickly cooled.

- The profiles solidify into their final shapes, showcasing various plastic forming processes in the high volume manufacturing process, including profile extrusion.

This process is not just about turning plastic into usable forms; it’s about precision and efficiency. Each step, from feeding the raw material to cooling the extruded product, is meticulously controlled to ensure high-quality results. Whether it’s producing stock plastic extrusions or custom plastic profiles, the plastic extrusion process is a marvel of modern manufacturing.

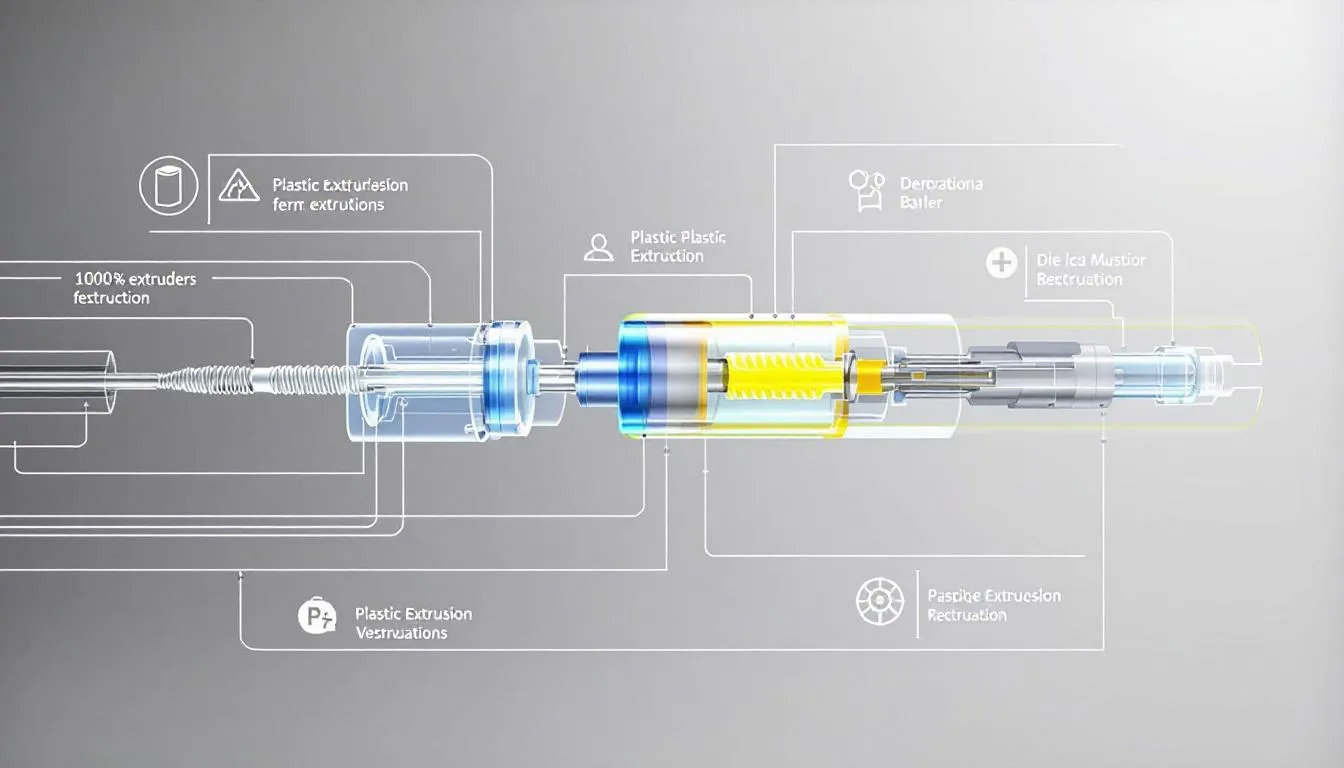

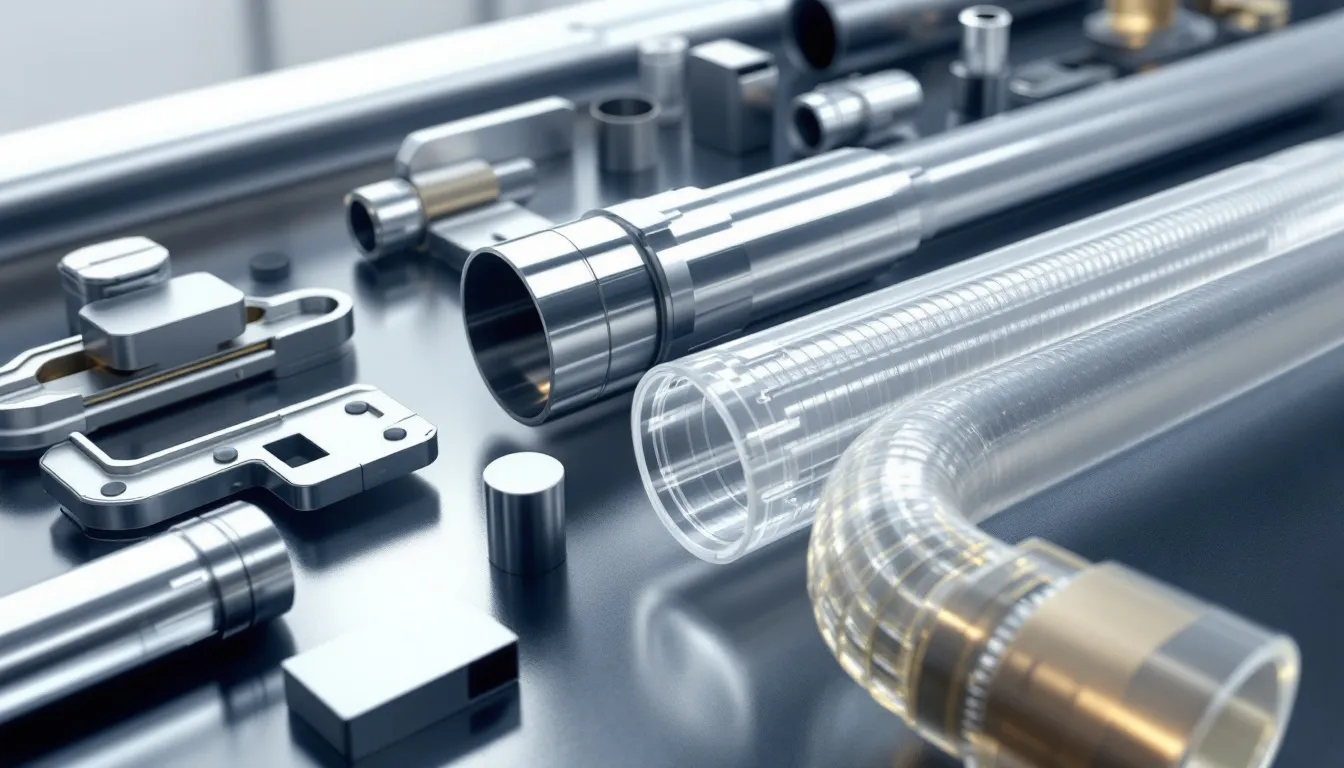

Key Components of Plastic Extruders

Understanding the key components is essential to appreciate the intricacies of plastic extrusion. Central to the process is the plastic extruder, a machine with several critical parts. The hopper stores raw plastic granules, which are then transported into the heated barrel through the feed throat.

Inside the barrel:

- The rotating screw heats and melts the plastic.

- The breaker plate filters the molten plastic and maintains the necessary pressure within the barrel.

- The molten plastic eventually reaches the annular dies, shaping the material into the desired profile, passing through the screen pack.

Think of the plastic extruder as a well-orchestrated symphony. The components work together to create a seamless extrusion process:

- The hopper and feed throat supply raw material steadily.

- The barrel and rotating screw melt and push the plastic forward in harmony.

- The breaker plate filters and maintains pressure.

- The die shapes the molten plastic into intricate profiles.

These components yield high-quality extruded plastic products with remarkable precision.

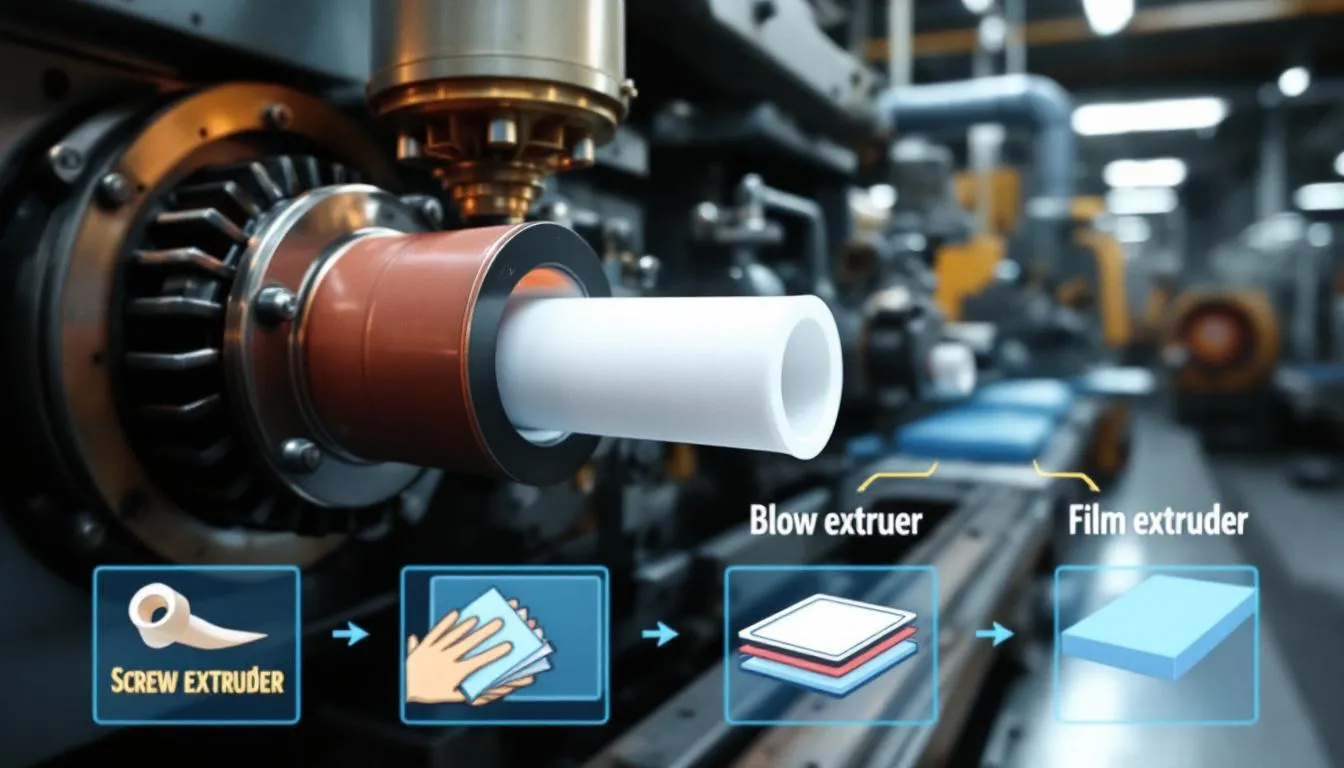

Types of Plastic Extruders

Plastic extrusion features two primary types of extruders: single screw and single extrusion head twin screw extruders. Single screw extruders are ideal for processing uniform materials, making them popular in the food and packaging industries due to their cost-effectiveness and ease of operation.

Twin screw extruders excel in mixing and processing complex materials, offering precise control over material blending to create products with specific characteristics. They are commonly used for advanced plastic applications that require high precision and consistency.

Imagine a scenario where a manufacturer needs to produce a high-volume batch of plastic film for food packaging. A single screw extruder would be the go-to choice, offering a cost-effective and straightforward solution. However, for a project requiring intricate blending of different viscous plastics, a twin screw extruder would be indispensable, ensuring the final product meets exacting standards.

Recognizing the differences between these individual extruders delivering helps manufacturers select the right tool for the job, ensuring optimal performance and quality.

Materials Used in Plastic Extrusion

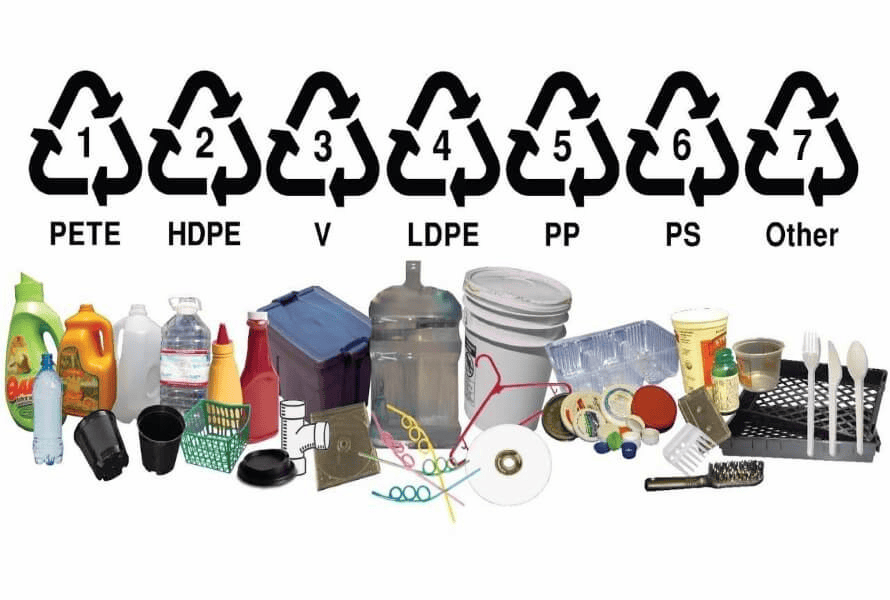

Plastic extrusion’s versatility comes from the wide range of thermoplastic materials it can utilize. Common materials include:

- Acrylonitrile Butadiene Styrene (ABS) for its strength and ease of molding

- Polycarbonate for its impact resistance and optical clarity

- High-Impact Polystyrene (HIPS), which combines standard polystyrene’s properties with enhanced toughness, increasing its resilience.

Materials and their valued properties:

- Polyethylene Terephthalate Glycol (PETG): valued for clarity, toughness, and recyclability; commonly used in packaging.

- Polyurethane: renowned for elasticity and durability.

- Rigid Polyvinyl Chloride (RPVC): preferred for strong, durable plastic profiles.

- Nylon (a type of polyamide): favored for strength and heat resistance; popular in demanding applications.

Additives can enhance these materials’ properties, making them more durable, flame-resistant, or UV-protected. This flexibility allows manufacturers to tailor the extrusion process to meet specific needs, from flexible packaging to rigid structural components. Choosing the appropriate materials and additives allows manufacturers to create extruded plastic profiles that adhere to the highest standards of performance and quality.

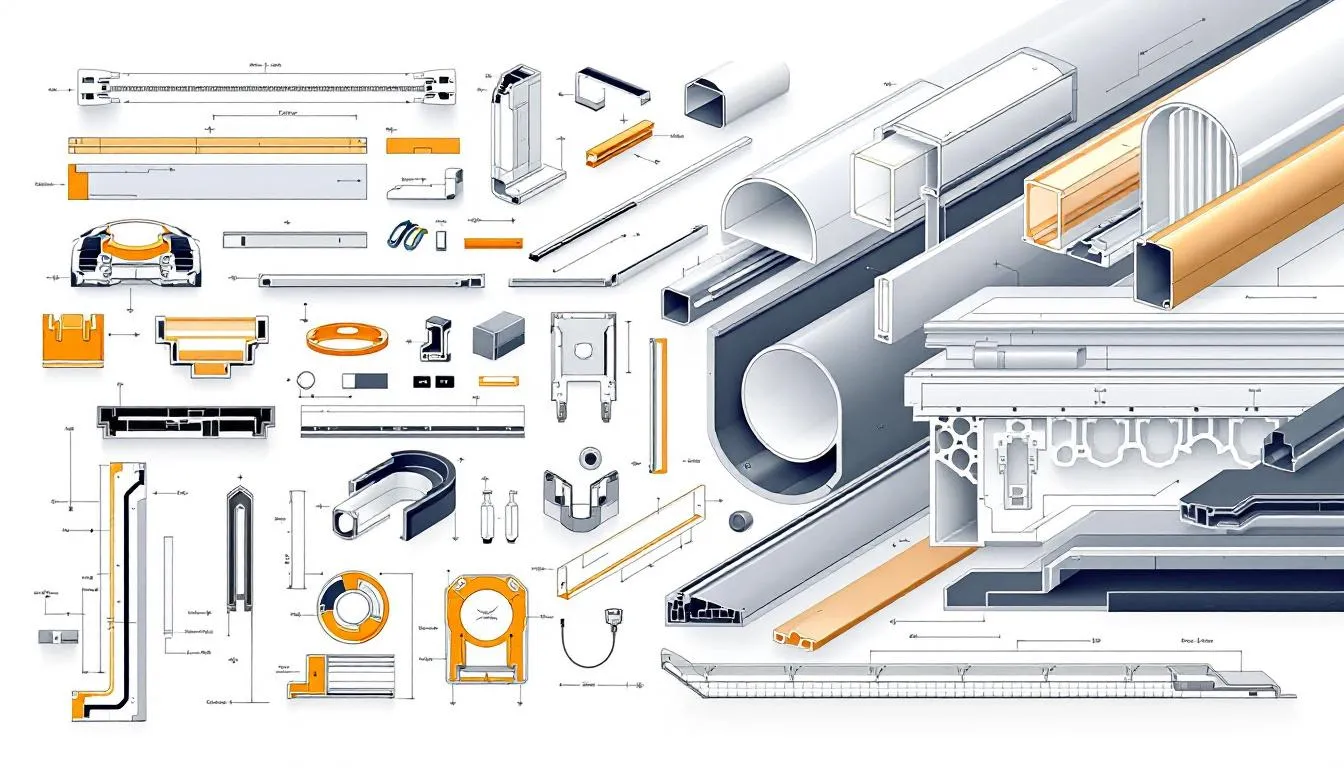

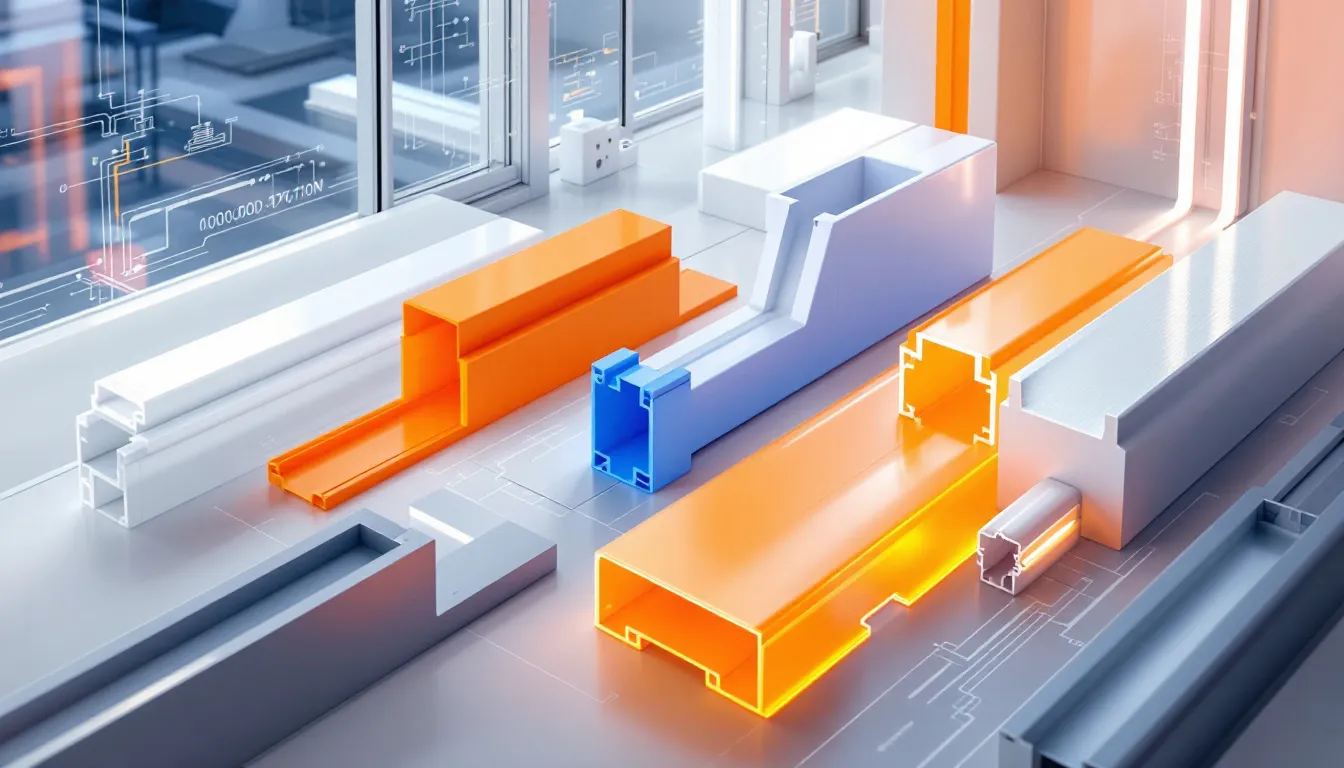

Custom Plastic Extrusions

Custom plastic extrusion provides numerous possibilities for businesses producing unique products tailored to niche market demands. The process can create various shapes, including custom shapes and extruded profiles:

- Sheets

- Tubes

- Custom profiles designed to meet project needs Custom extrusion’s flexibility allows for quick and cost-effective solutions, making it attractive for many industries.

Materials in custom extrusion can be tailored for specific needs, such as UV protection and custom color concentrates. Co-extrusion of multiple materials is also possible, allowing for even more customization. A reliable manufacturer should offer capabilities like tooling design and build, prototyping, and all secondary operations to ensure quality and efficiency.

Consider a company needing a custom plastic profile with specific UV resistance for outdoor use. The manufacturer designs the tooling and prototypes the product in its desired form, ensuring it meets all aesthetic requirements before full-scale production. This customization allows them to create profiles that not only meet but exceed expectations, providing unique advantages and a competitive edge in the market.

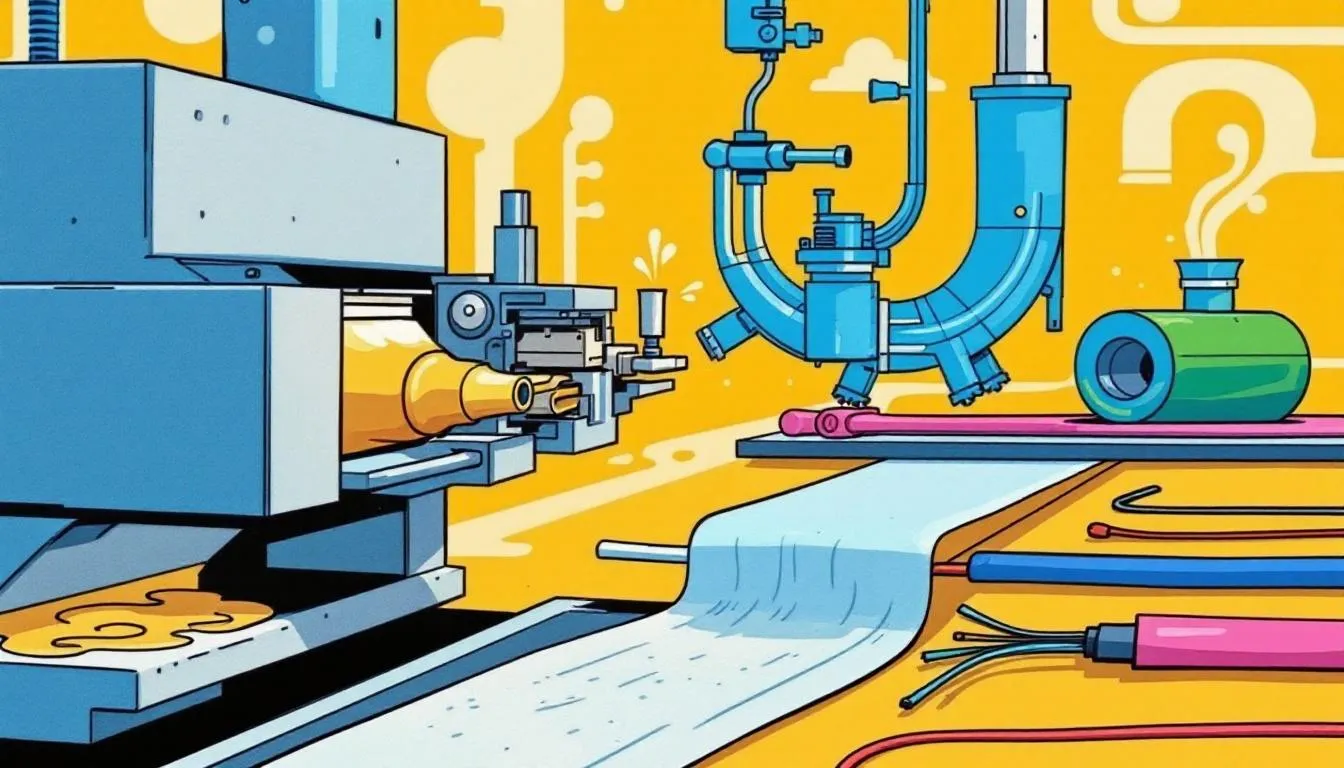

Co-Extrusion Techniques

Co-extrusion involves the simultaneous extrusion of multiple material layers using two or more extruders. This process bonds different plastics into layered structures without mixing them, enhancing the final product’s performance characteristics through plastic co extrusion.

Co-extrusion is ideal for efficiently producing various products like sheets, tubes, and seals in large quantities. For instance, food packaging films often require multiple layers, each serving a different protective function. One layer might provide moisture resistance, while another offers chemical resistance, all achieved through co-extrusion.

Consider a packaging manufacturer’s production line in the packaging industry. Multiple extruders feed different materials into a single extrusion line, creating multi-layered plastic film. Each layer is carefully controlled to provide specific properties, resulting in a product that meets stringent industry standards. Co-extrusion enhances product performance and enables innovative solutions to complex manufacturing challenges.

Secondary Processes and Finishing Options

Secondary processes and finishing options are crucial for achieving the desired quality and functionality of extruded plastic products. Techniques like CNC trimming precisely shape plastic parts by removing excess material through programmed routes in manufacturing processes. Fastening techniques like screws and rivets attach plastic components without heat, ensuring strong and stable assemblies.

Ultrasonic welding and heat staking join plastic components by applying high-frequency vibrations or localized heat and pressure to fuse parts together. Decorative techniques like pad printing can apply multiple colors to complex plastic surfaces, enhancing the final product’s aesthetic appeal.

A cooling system quickly solidifies the extruded plastic product after it passes through the die, ensuring dimensional stability and quality. These secondary processes and finishing options turn raw extrusions into finished products that meet high standards of precision and performance, including the use of air cooling rolls.

Applications of Plastic Extrusions

Plastic extrusions have varied applications, just like the materials and techniques used to produce them. Their durability makes plastic extrusions resistant to corrosion, moisture, and chemicals, suitable for harsh conditions like those in the construction and automotive industries. Their insulating properties enhance energy efficiency, benefiting building designs.

Plastic extrusion is widely used to create weather stripping, fencing, and wire insulation, essential components in various industries. The process can produce both flexible and rigid products, suitable for applications including medical tubing and adhesive tapes. The lightweight properties of plastic extrusions make handling, transport, and installation easier, broadening their range of applications.

Consider the versatility of plastic extrusions in everyday life. From the weather stripping that insulates your home to the medical tubing that saves lives, their impact is profound. Industries like automotive, building and construction, and agriculture rely on these durable and versatile products to meet specific needs.

Benefits of Using Plastic Extrusions

Plastic extrusions offer numerous and compelling benefits. The process is cost-effective for large-scale production, allowing continuous runs once the initial tooling is established. Compared to alternatives like metal or wood, plastic extrusion generally offers lower production costs, making it economically viable for many industries.

Plastic extrusion is known for:

- Its efficiency, enabling rapid production of both simple trim pieces and complex dual-layered tubes.

- Minimizing waste, making it an environmentally friendly manufacturing option.

- Its versatility, allowing for a wide variety of customized shapes, sizes, colors, and finishes to meet diverse market demands in plastics extrusion.

Picture a production line churning out thousands of components with minimal waste and maximum efficiency. Each piece is precisely shaped and customized to meet specific requirements, from simple trim pieces to complex multi-layered tubes. The efficiency, cost-effectiveness, and environmental benefits of plastic extrusion make it a preferred choice for manufacturers globally.

Choosing the Right Plastic Extrusion Manufacturer

Selecting the right plastic extrusion manufacturer is crucial for your project’s success. Key considerations include material selection, assessing a supplier’s capabilities to ensure their offerings match your project requirements. Maintaining effective communication with the supplier to reduce production disruptions. Enhancing overall project management through collaboration.

Knowing pricing structures and contract terms early prevents unexpected manufacturing experience costs. Choosing a manufacturing partner with extensive experience and a proven track record ensures your plastic extrusion needs are met with high standards of quality and efficiency.

Summary

In summary, plastic extrusion is a versatile and efficient manufacturing process that transforms raw plastic material into a wide array of products. From understanding the basic principles to exploring advanced techniques like co-extrusion, we’ve covered the key components, materials, and benefits of plastic extrusions. Whether you’re in the automotive, construction, or agriculture industry, plastic extrusions offer durable, cost-effective, and customizable solutions.

As you consider your manufacturing needs, remember the importance of selecting the right plastic extrusion manufacturer. With the right partner, you can achieve high-quality results that meet your specific requirements and exceed your expectations. Embrace the possibilities of plastic extrusion and discover how it can elevate your projects to new heights.

]]>Key Takeaways

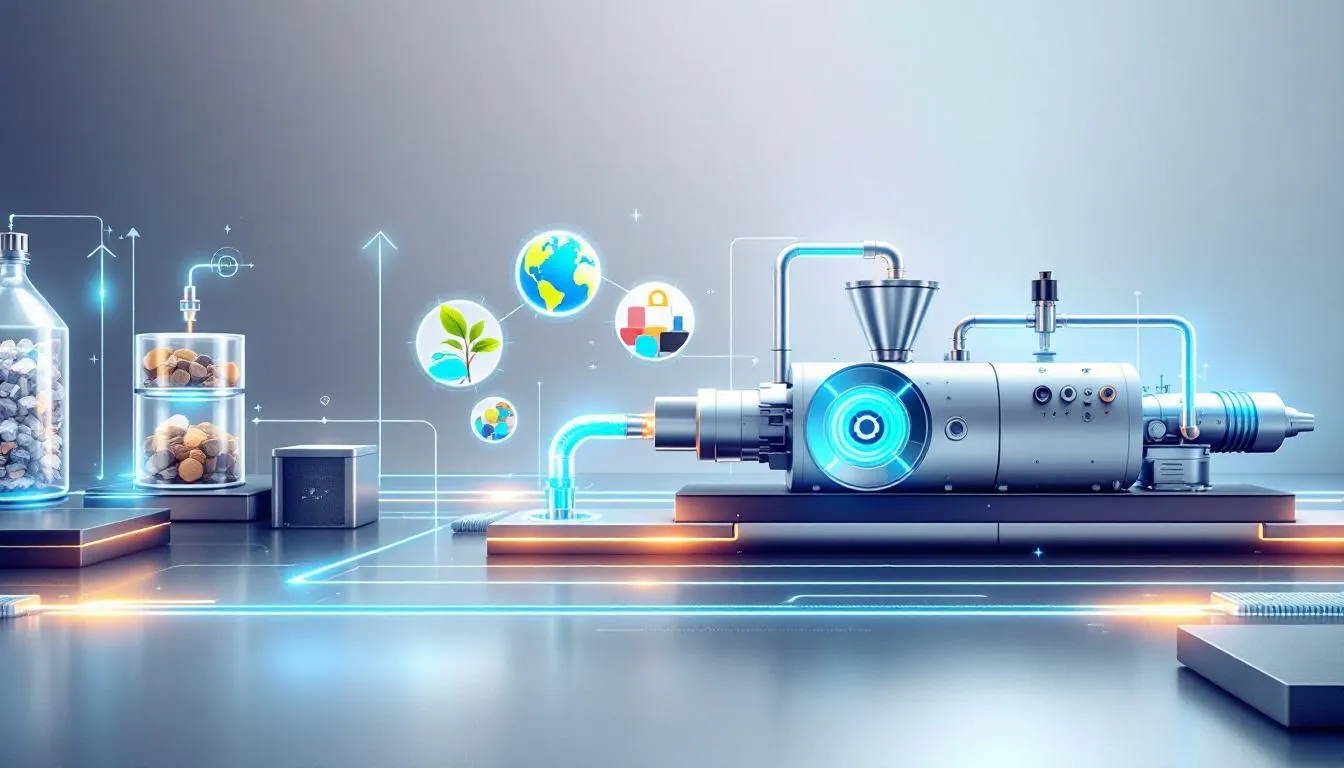

- Recycled plastic extruders convert waste plastics into reusable materials, playing a critical role in sustainability and reducing environmental waste.

- Key components, such as the hopper, barrel, and screws, are essential for the efficient operation of recycled plastic extruders, facilitating the transformation of plastics into high-quality products.

- Choosing the right recycled plastic extruder involves considering processing capacity, energy costs, and the specific types of plastics it can handle, ensuring optimal efficiency and effectiveness in recycling operations.

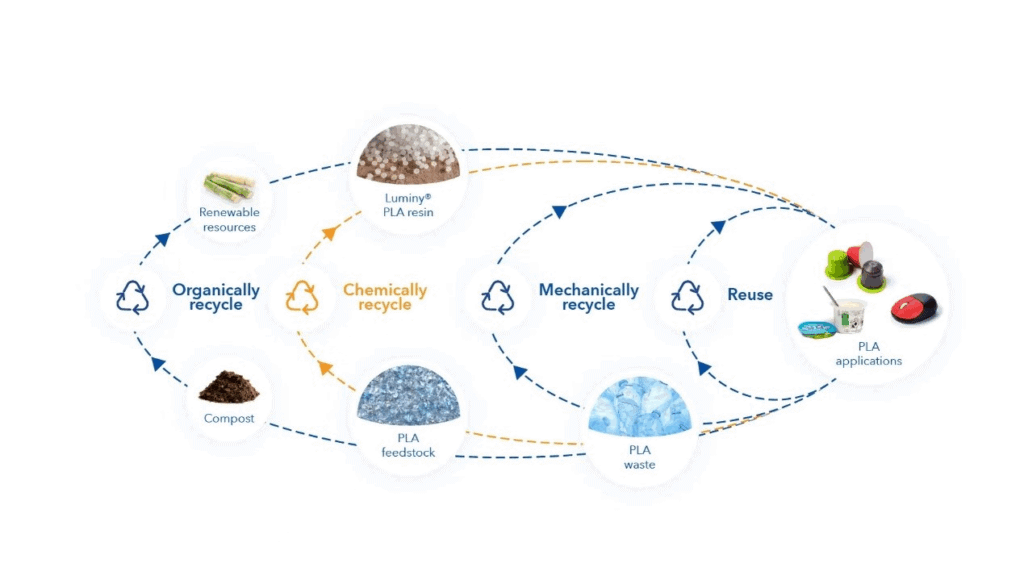

Understanding Recycled Plastic Extruders

Recycled plastic extruders are pivotal in the fight against plastic waste. These plastic recycling machines transform discarded plastics into reusable materials, playing a vital role in supporting sustainability and cost-effectiveness. The process involves converting scrap plastic into high-quality pellets, which can then be used in various manufacturing processes, thereby reducing environmental waste.

Recycled plastic extruders work by heating, compressing, and shearing plastic, allowing it to be reshaped into new products. Repurposing plastic waste with these machines significantly reduces landfill contributions, tackling one of today’s major environmental challenges.

Plastic waste is first collected and sorted by type and quality. These sorted plastics are then fed into the extruder for transformation. This not only supports environmental sustainability but also showcases the potential of plastic recycling technologies in creating new products from what was once waste.

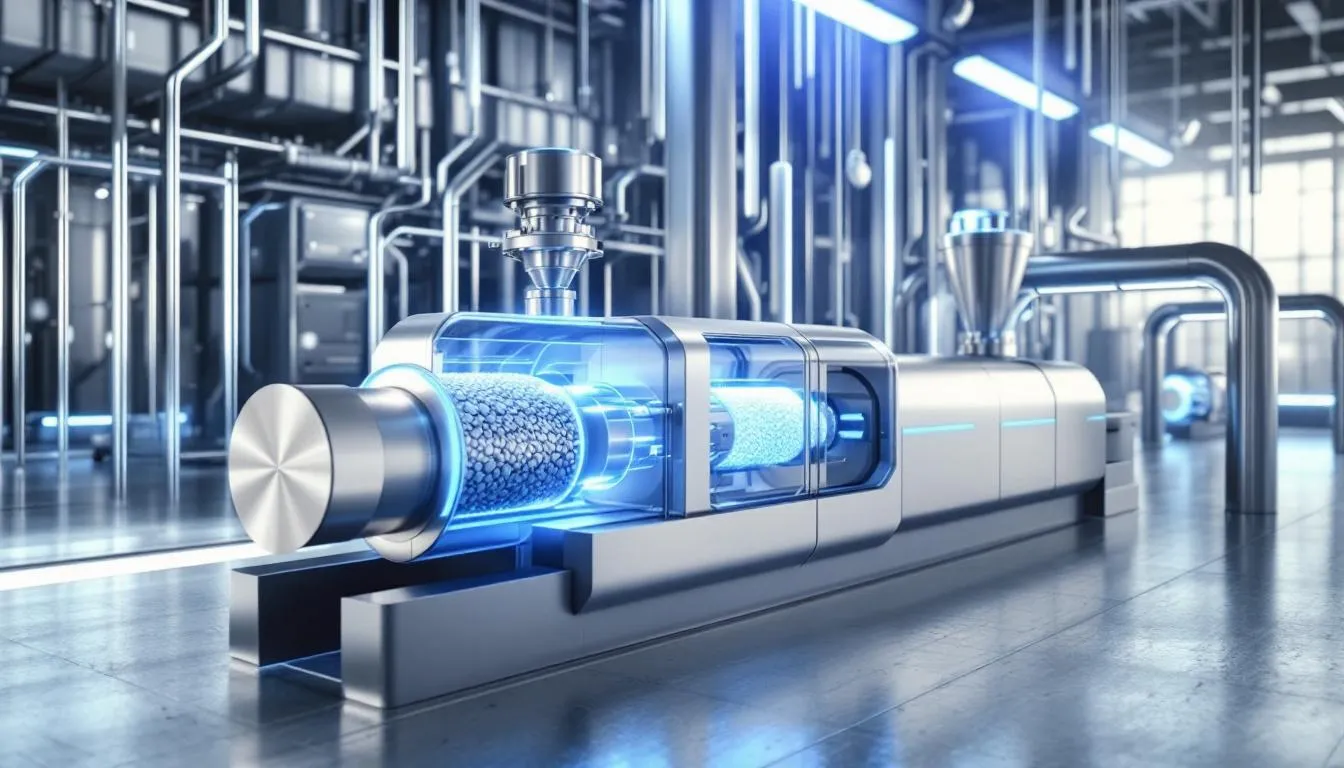

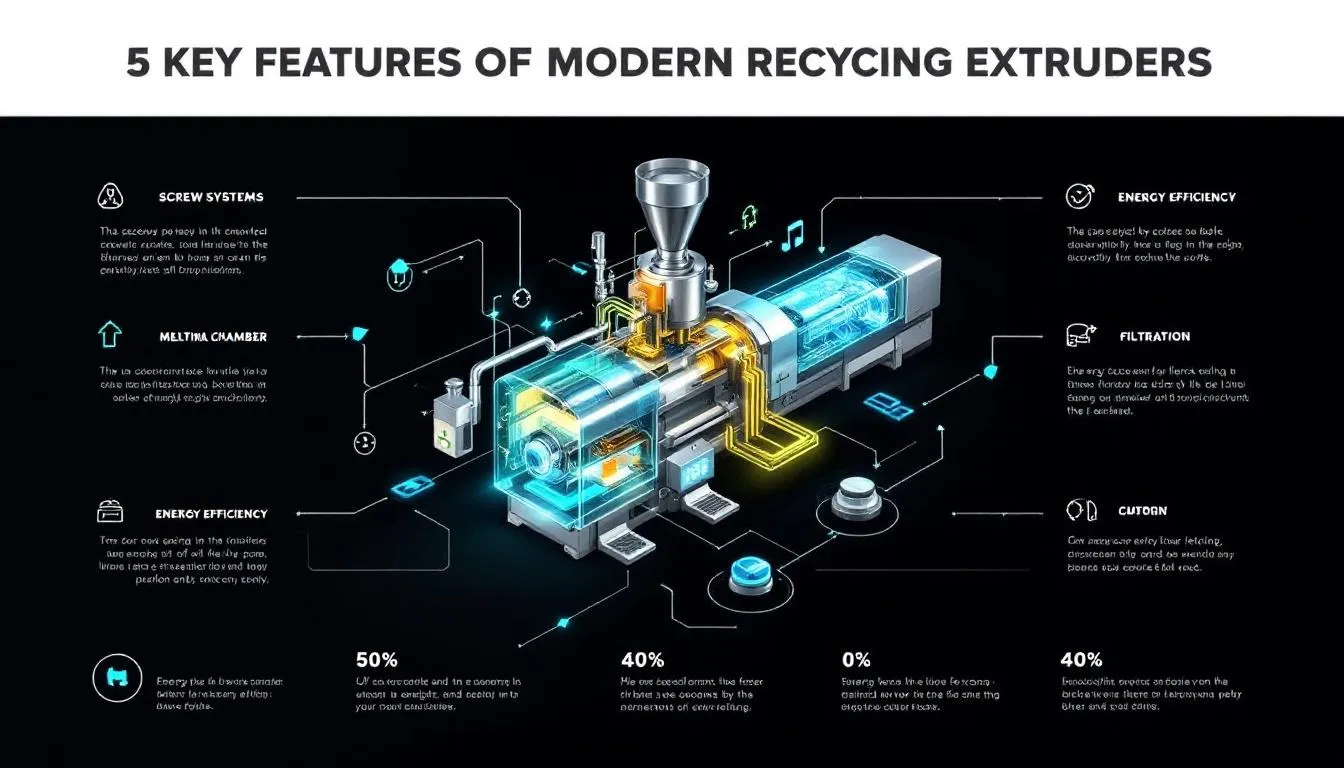

Key Components of a Recycled Plastic Extruder

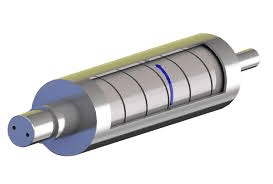

Key components of a recycled plastic extruder include the hopper, which acts as the entry point for plastic feedstock. The barrel houses the screws and controls the temperature, ensuring the plastic is adequately melted for further processing.

Heaters provide the thermal energy needed to melt the plastic inside the barrel. The screws, considered the heart of the extruder, move, compress, and mix the plastic, ensuring it reaches a uniform molten state.

The molten plastic then reaches the die, which shapes it into its final form. A cooling system solidifies the melted plastic upon exiting the die, ensuring it retains the desired shape. These components are vital for efficiently transforming plastic waste into valuable products.

How Recycled Plastic Extruders Work

The operation of recycled plastic extruders starts with shredding the collected plastic waste, increasing its surface area for efficient melting. The shredded plastic is then heated within the extruder barrel, converting it into a molten state for further processing.

Advanced filtration systems remove contaminants from the molten plastic, ensuring high-quality end products that are manufactured. The molten plastic is then shaped through moulds, which define the final form, dimensions, and characteristics of the extruded product.

The extrusion process involves the following steps and outcomes:

- After shaping, the extruded plastic product is rapidly cooled to maintain its form.

- The process enables the creation of various products, including pellets and sheets, from recycled plastic.

- Once cooled, the solidified plastic can be cut or further processed for other applications.

This highlights the versatility and efficiency of this recycling method.

Benefits of Using Recycled Plastic Extruders

Recycled plastic extruders offer numerous benefits, making them indispensable in modern recycling processes:

- They help recycle materials, significantly reducing plastic pollution.

- Manufacturing recycled plastic products locally decreases transportation emissions, further reducing plastic pollution.

- US manufacturers adhere to strict environmental standards, minimizing pollution.

Modern plastic extrusion machinery is designed to optimize energy consumption, reducing greenhouse gas emissions. Recent legislative changes are promoting the use of recycled materials in plastic production, boosting demand for energy-efficient practices. Using recycled plastic extruders enhances material efficiency, resulting in less raw material waste during production.

These machines conserve resources and support sustainable practices by reducing waste and promoting energy efficiency. Their role in recycling processes is essential for creating a more sustainable and efficient future, highlighting the importance of environmental stewardship.

Applications of Recycled Plastic Extruders

Recycled plastic extruders have a wide range of applications across various industries. In the automotive industry, they are used to create parts like door seals and bumper components, which need to withstand wear and environmental conditions. In the medical field, extruded plastic provides components like IV tubing and catheters that require sterility and chemical resistance.

Consumer packaging also benefits from plastic extrusion, resulting in lightweight and hygienic containers that help preserve product quality. In the construction industry, plastic extrusion is widely utilized for making durable plastic materials like PVC pipes and window frames. These applications demonstrate the versatility and durability of products created through plastic extrusion.

Household items such as storage containers and decorative trims are often produced using plastic extrusion. Innovative technologies like CPM Extricom Extrusion recycle PET waste into material suitable for food-grade applications, overcoming challenges like moisture content. The RingExtruder RE® from CPM offers enhanced control over the recycled product’s color, crucial for applications requiring aesthetic consistency. Additionally, polyethylene terephthalate is a key material in the production of these containers.

These examples highlight the extensive and impactful use of recycled plastic extruders in various sectors.

Choosing the Right Recycled Plastic Extruder for Your Needs

Choosing the right recycled plastic extruder ensures maximum efficiency and meets specific needs. Consider factors like intended use, processing capacity, and storage capacity of output bales. Machine throughput and capacity determine its efficiency, with options ranging from small-scale operations processing 20-50 kg per hour to large-scale operations handling up to 2,200 kg/h.

Key considerations include:

- Energy costs, representing around 10-20% of overall production expenses.

- Raw material costs, comprising 50-70% of total expenses.

- Ensuring the machine can process specific types of plastics with particular resin codes, such as PET, to align with your intended application. Raw materials play a crucial role in determining overall production efficiency.

For small-scale recycling machines, prioritize ease of use, security measures, and low noise levels. Evaluating these factors carefully helps businesses select the most appropriate and efficient extrusion machine for their recycling needs.

Maintenance Tips for Recycled Plastic Extruders

Regular maintenance ensures the longevity and efficiency of recycled plastic extruders. Key maintenance practices include:

- Inspecting and lubricating moving parts regularly to minimize wear and tear.

- Scheduling routine maintenance checks to identify potential issues before they escalate.

- Keeping detailed maintenance logs to track the extruder’s performance and servicing history.

To maintain optimal operating conditions and ensure consistent high-quality production, it is important to:

- Monitor temperature and pressure settings regularly.

- Inspect the screw and barrel for wear or damage.

- Assess output quality to detect deviations in product specifications.

To maintain the extruder properly:

- Clean the extruder thoroughly after each production run to prevent material contamination.

- Use compatible cleaning agents to help maintain the machine’s integrity.

- Identify abnormal noises or vibrations early, as they can indicate mechanical issues needing attention.

Following the manufacturer’s guidance for troubleshooting specific extruder problems ensures effective maintenance.

Cost Considerations for Recycled Plastic Extruders

Financial considerations are crucial when investing in recycled plastic extruders:

- Initial costs for small models can range from $10,000 to $30,000.

- Larger models can cost between $90,000 and $200,000.

- Choosing energy-efficient machinery can substantially reduce operational expenses and lessen environmental impacts, making them a wise long-term investment.

Electricity usage during shredding or crushing significantly affects operating costs. Maintenance costs typically amount to about 5-10% of the equipment’s cost each year, and labor costs should be considered if the extruder is not self-built.

Budget considerations are crucial when selecting recycling machines, as they represent a significant investment. Understanding and planning for these costs allows businesses to make informed decisions, balancing initial investment with long-term operational savings.

Case Studies: Successful Use of Recycled Plastic Extruders

Real-world examples of recycled plastic extruders in use can provide valuable insights and inspiration. For instance, Prad and Lala from Chennai, India, use their extrusion machine to make furniture, demonstrating practical and creative possibilities. Joop from Haute Plastique in Rotterdam creates sleek, aesthetically pleasing products from recycled materials, showcasing the machines’ potential.

Businesses worldwide are successfully using recycled plastic extruders to turn waste into valuable products. These case studies illustrate the transformative impact of these machines, highlighting their versatility and effectiveness in various business applications.

Summary

Recycled plastic extruders play a pivotal role in addressing plastic pollution by transforming waste into valuable products. Their benefits extend beyond environmental sustainability, offering energy efficiency and cost savings for businesses. The diverse applications of these machines across industries, from automotive to medical to consumer packaging, showcase their versatility and importance.

Proper maintenance and understanding cost considerations are essential for maximizing the efficiency and longevity of recycled plastic extruders. The success stories from around the world highlight the potential of these machines to revolutionize plastic recycling and contribute to a sustainable future.

As we continue to innovate and adopt sustainable practices, recycled plastic extruders will remain at the forefront of the fight against plastic pollution. Let’s embrace these technologies and work towards a greener, cleaner planet.

]]>Key Takeaways

- Leading manufacturers such as Coperion, Leistritz, and KraussMaffei Berstorff emphasize quality and innovation in plastic extrusion, catering to various industrial needs.

- Understanding the types of plastic extruders, including single and twin screw extruders, is essential for selecting the appropriate machinery for specialized applications.

- Recent advancements in plastic extrusion technologies focus on sustainability and energy efficiency, driving the industry towards improved production practices and environmental responsibility.

Leading Plastic Extruder Manufacturers

Choosing the right plastic extruder manufacturer is crucial for maintaining quality and reliability in your production line. Among the leaders in this field, Coperion stands out for its precision-engineered twin screw extruders, renowned for their high throughput and exceptional mixing capabilities. Coperion’s commitment to innovation makes them a go-to choice for many industries.

Equally prominent, Leistritz offers versatile twin screw extruders that cater to a wide range of applications, including pharmaceuticals and food. Their machines are designed for flexibility and efficiency, making them suitable for various complex extrusion processes.

Another key player, KraussMaffei Berstorff, specializes in extrusion technology for industries such as pipe and profile extrusion, demonstrating their extensive expertise in the field.

These manufacturers stand out due to their dedication to quality and innovation. Companies like Davis-Standard and Amut S.p.A. offer comprehensive extrusion solutions across multiple sectors, underscoring the importance of choosing a partner with a proven track record.

From the innovative Kneading Disc Technology of BUSS AG to the century-long experience of the Reifenhäuser Group, these manufacturers epitomize excellence in the plastics industry.

Types of Plastic Extruders

Knowing the various types of plastic extruders helps in selecting the right machinery for your needs. Single screw extruders are the workhorses of simpler extrusion processes, primarily melting and conveying materials to form basic shapes. These individual extruders are ideal for producing straightforward profiles where complex mixing is not required, especially when using a single extrusion head.

Twin screw extruders, on the other hand, are ideal for high-speed production and superior mixing capabilities. Their modular screw design allows for easy customization, making them suitable for a variety of applications, from consumer goods to industrial components. One screw counter-rotating twin screw extruder and rotating screw are particularly efficient for shaping operations involving shear-sensitive materials, providing a tailored solution for specific needs.

Co-extruders enhance versatility by processing different materials simultaneously, creating multi-layered products with varied properties. This capability is particularly useful in applications requiring distinct material characteristics, such as barrier properties in packaging films or multi-functional profiles in construction. The ability to process multiple materials concurrently highlights the adaptability and efficiency of modern extrusion lines, especially when utilizing two or more extruders, including individual extruders delivering co extrusion.

Custom Plastic Extrusion Solutions

Custom plastic extrusion provides unmatched flexibility, enabling businesses to create unique designs with specific cross-sections and wall thicknesses. This is particularly beneficial for industries that require specific shapes and sizes that stock plastic extrusions cannot provide. Whether you need complex profiles or simple custom shapes, custom plastic extrusion can meet your exact specifications, including extruded plastic profiles.

A key advantage of custom plastic extrusion is its cost-effectiveness, particularly for medium to high-volume manufacturing processes. By leveraging custom solutions, businesses can achieve quick turnaround times and enhanced functionality, often integrating features like snap-fits to reduce assembly steps. This streamlines manufacturing processes and enhances product performance.

Additionally, the variety of thermoplastic materials available in custom extrusion solutions meets specific needs like flame resistance and chemical compatibility. Companies that excel in customization offer tailored solutions to meet unique project specifications, providing secondary processes like notching, drilling, and heat welding to enhance the final product. Custom plastic profiles can be designed to fit unique applications, ensuring that every detail aligns with your requirements. Custom fabrication can also play a crucial role in achieving these tailored solutions.

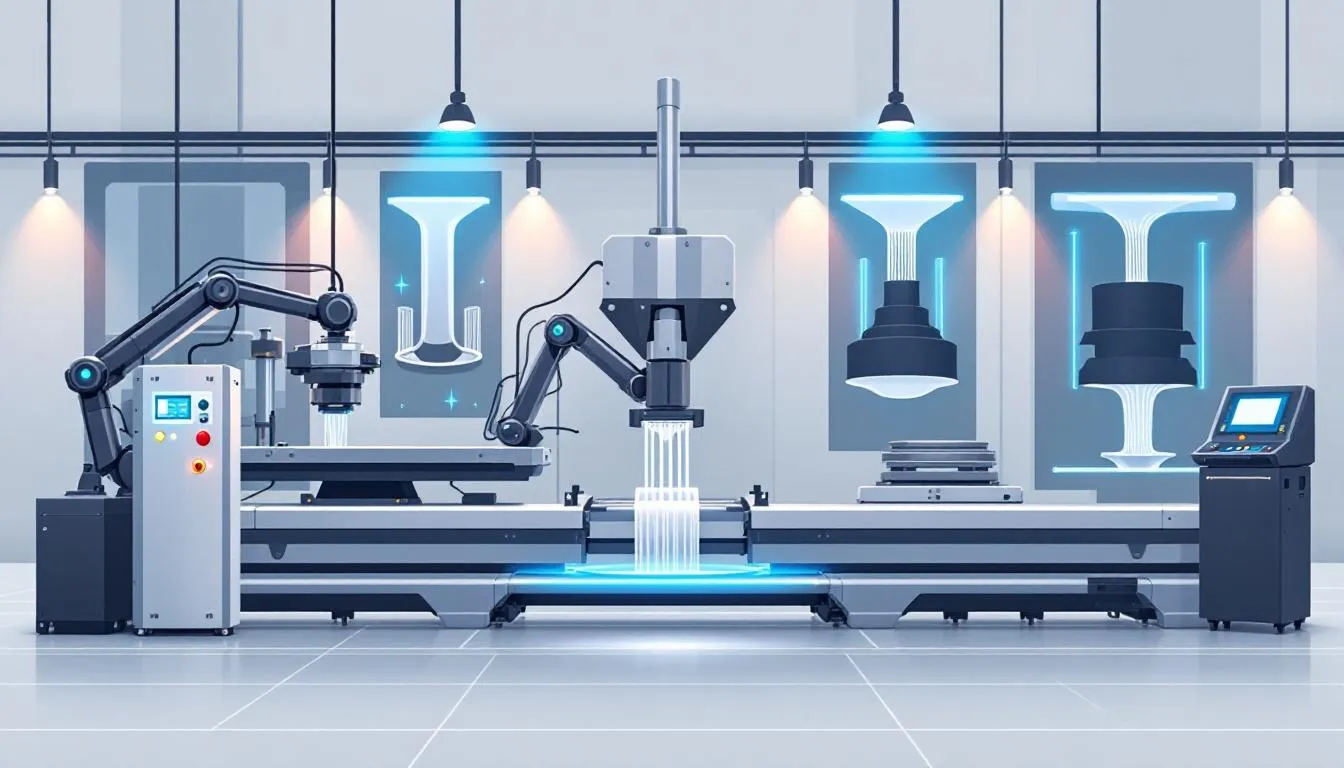

Advanced Plastic Extrusion Technologies

Advanced plastic extrusion technologies have revolutionized the industry, enhancing efficiency and sustainability in production processes. Modern extrusion lines feature energy-efficient drive systems that significantly reduce energy consumption, aligning with the industry’s push towards sustainability. These technologies not only lower operational costs but also minimize the environmental impact of manufacturing, particularly in the context of an extrusion line.

Automation and digital technologies lead this transformation, facilitating real-time monitoring and adjustments to maintain product quality and consistency. Automated monitoring systems are integral in modern plastic sheet extrusion lines, enhancing efficiency and ensuring that the final products meet stringent quality standards. Closed-loop systems further optimize material flow, facilitating precise control over the extrusion process.

Precision engineering improvements allow manufacturers to achieve tighter tolerances and better surface finishes on extruded products. Advanced simulation tools are now being used to optimize design and production processes, reducing development time and improving product quality. The integration of these technologies ensures that modern extrusion lines are capable of delivering high-quality products efficiently.

Materials Used in Plastic Extrusion

Material selection in plastic extrusion is crucial for attaining the desired properties in the final product. Common thermoplastic materials and plastic materials include:

- Polyvinyl chloride (PVC): widely used for pipes, films, and electrical wire insulation due to its excellent formability and durability.

- Polyethylene terephthalate (PET): offers unique benefits (not specified in the text).

- Acrylonitrile butadiene styrene (ABS): offers unique benefits (not specified in the text).

ABS, known for its strength and flexibility, finds applications in automotive and consumer goods where these properties are essential. Polyethylene (PE) and polypropylene are also popular choices, particularly in packaging and consumer goods, due to their versatility and ease of processing. Material selection is often based on the specific requirements of the application, such as chemical resistance, impact strength, and thermal stability.

Materials like polycarbonate and nylon (polyamide) are selected for their unique properties. Polycarbonate is valued for its impact resistance and optical clarity, making it suitable for products like eyewear lenses and safety equipment. Nylon’s strength and heat resistance make it ideal for various industrial applications.

The diverse range of available materials ensures that plastic extrusion can meet the demands of virtually any industry.

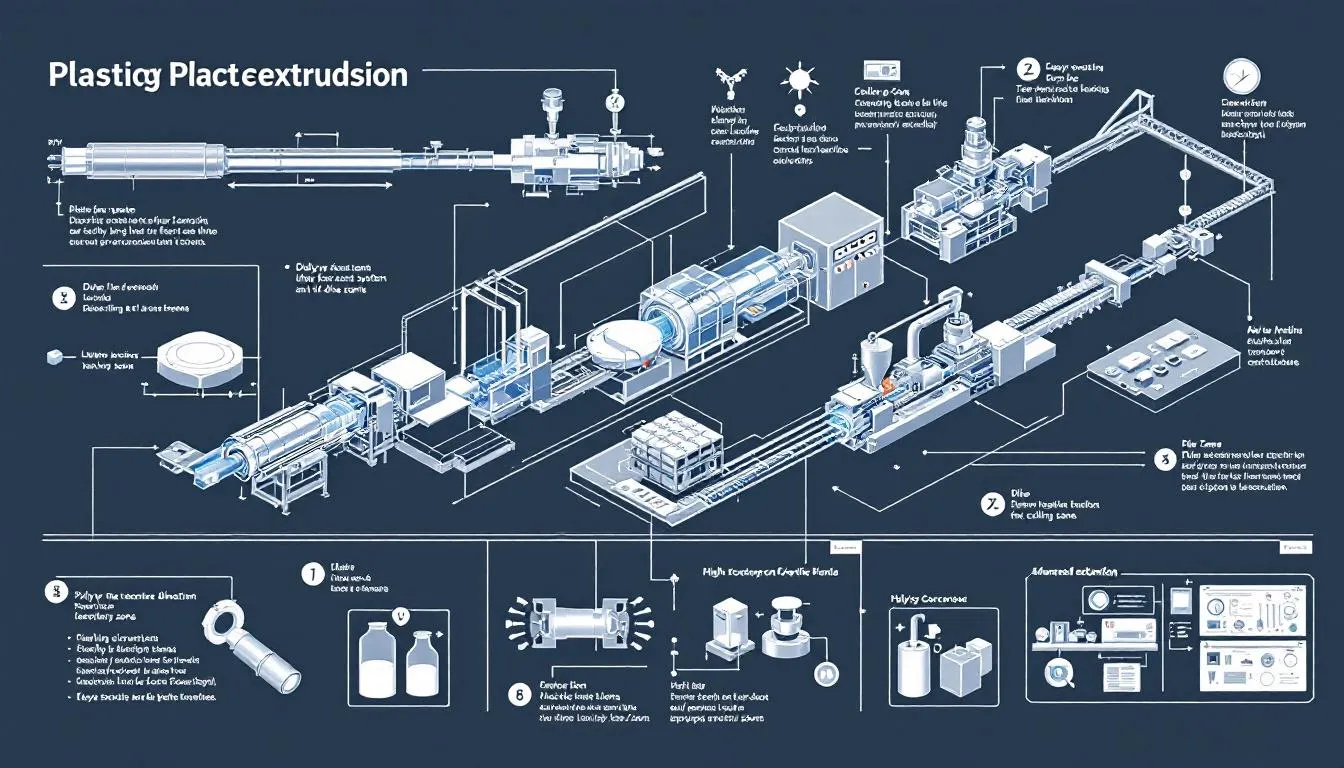

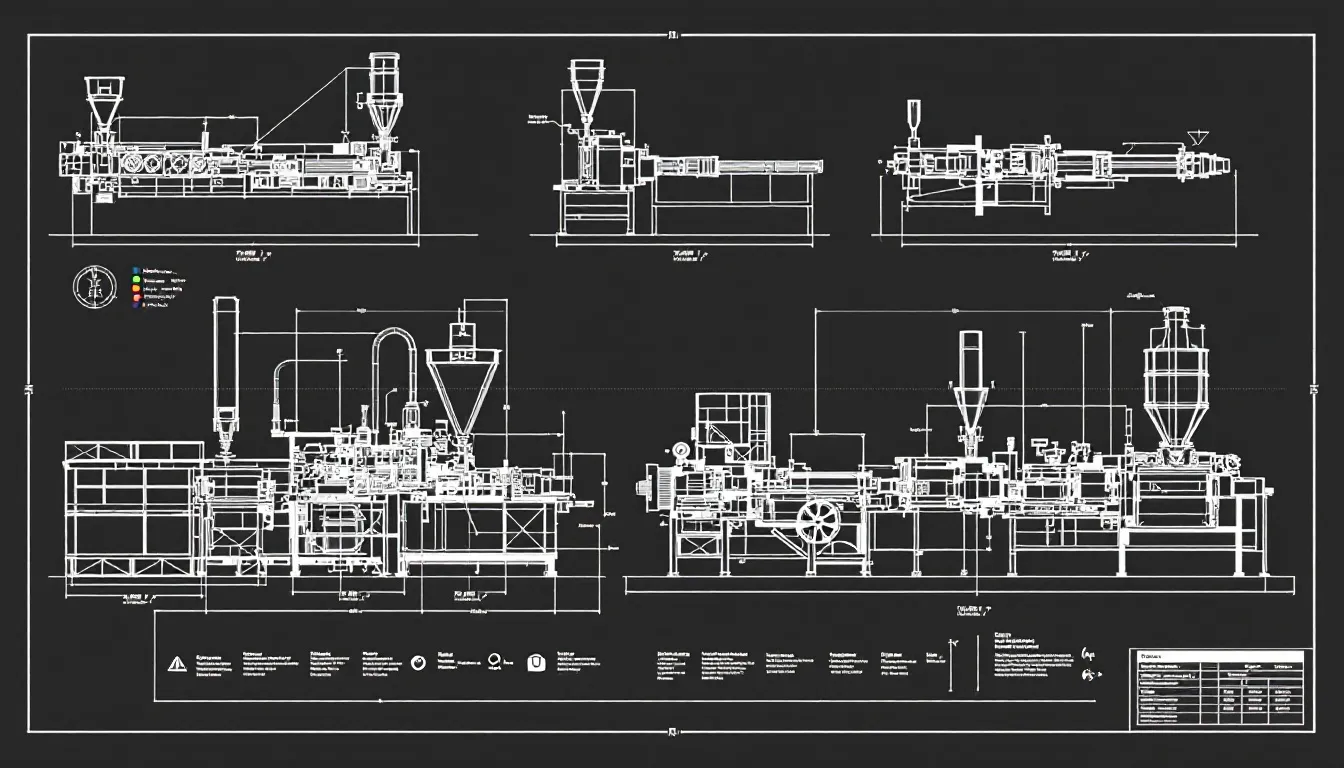

The Plastic Extrusion Process

Plastic extrusion is a continuous, high-volume manufacturing process that shapes raw thermoplastic materials into specific forms through various plastic forming processes. The process includes the following steps:

- Introduction of thermoplastic raw material into the extruder via a hopper.

- Heating the material to a specific melt temperature within the heated barrel.

- Melting facilitated by friction and pressure inside the barrel. Plastics extrusion is an essential technique in this context, including plastic co extrusion.

The plastic extrusion process involves the following steps:

- Once the plastic material is in a molten state, it is filtered through a screen pack to remove any contaminants before being shaped into its final shape.

- The design of the die through which the molten plastic passes determines the shape of the extruded product.

- Cooling methods, such as water baths or cooling rolls, are employed to solidify the extruded profiles, ensuring that they maintain their form and dimensional stability.

Real-time monitoring and in-line inspection are essential for ensuring consistent material flow and high-quality production runs. Specialized machinery plays a vital role in maintaining the efficiency, production speed, and quality of the plastic extrusion process.

The versatility of extrusion allows for the creation of products that can be used as-is or further fabricated into complex assemblies, such as pipes, tubing, and plastic films.

Applications of Plastic Extrusions

Plastic extrusions are essential in numerous industries due to their versatility and durability. In the packaging industry, materials such as High-Impact Polystyrene (HIPS) and Polyethylene Terephthalate (PET) are used to create plastic film and sheets that enhance product protection and extend shelf life. These extruded materials are essential for consumer goods and food packaging, providing both strength and recyclability.

In the medical field, plastic extrusion is crucial for producing compliant tubing and complex components like catheters, which are essential for various medical devices. The automotive industry also benefits significantly from plastic extrusions, using them to manufacture parts such as weather seals, gaskets, and fluid transfer tubing due to their chemical resistance and durability.

Construction applications include the use of extruded plastics for windows and doors, contributing to energy efficiency and quick installation. The solar industry leverages plastic extrusion to produce components like frames for solar panels, enhancing durability and longevity. These diverse applications underscore the integral role of plastic extrusions in modern industry.

Benefits of Working with Top Manufacturers

Partnering with leading plastic extruder manufacturers offers numerous advantages, ensuring efficient and reliable production processes:

- Top manufacturers operate their machinery continuously, minimizing the risk of inventory shortages.

- Continuous operation ensures steady production.

- This continuous operation is crucial for maintaining supply chain stability and meeting high-volume demands.

Access to innovative solutions in production techniques is another key benefit, providing unique advantages. Experienced manufacturers can create complex shapes and customized features, offering tailored solutions for specific needs. Additionally, reputable manufacturers offer engineering support to optimize the design and efficiency of the extrusion process, ensuring that every product meets high-quality standards.

Quality standards are crucial when selecting a manufacturing partner. Leading manufacturers adhere to:

- Strict quality controls, including relevant ISO certifications, ensuring product reliability and performance without compromising quality

- Strong after-sales support

- Transparent communication, ensuring that any issues are promptly addressed and resolved

How to Choose the Right Manufacturer

Choosing the right plastic extruder manufacturer requires careful consideration of several factors. Here are some steps to help you in the process:

- Utilize directories of leading extruded plastics manufacturers to compare their capabilities and offerings.

- Use this comparison to identify manufacturers that can meet your specific needs.

- Determine whether you require standard profiles or customized solutions to guide your selection.

Request samples helps evaluate the quality of a manufacturer’s products. Samples provide a tangible representation of the manufacturer’s capabilities and allow you to assess whether their products meet your desired form and material selection criteria. This due diligence ensures that you choose a manufacturing partner who can deliver high-quality, reliable extrusions for your applications.

Future Trends in Plastic Extrusion

The future of plastic extrusion is driven by advancements in sustainability, energy efficiency, and precision. The use of recyclable materials is becoming increasingly prevalent, promoting eco-friendly manufacturing practices. This shift towards sustainability is driven by the growing demand for environmentally responsible production methods.

Technological advancements, including automated monitoring and closed-loop systems, are revolutionizing the plastic extrusion industry. These technologies enable real-time adjustments and enhance production efficiency, ensuring steady volumetric throughput and consistent quality.

Energy efficiency and precision engineering will continue to drive innovation in the plastics industry, setting new production standards.

Summary

Plastic extrusion is a dynamic and essential process in modern manufacturing, offering unparalleled flexibility and efficiency. Understanding the capabilities of top manufacturers, the types of extruders available, and the advanced technologies driving the industry is crucial for making informed decisions. From the materials used to the applications of extruded products, every aspect of plastic extrusion plays a vital role in achieving high-quality outcomes.

As the industry continues to evolve, embracing sustainability and technological advancements will be key to staying ahead. By partnering with reputable manufacturers and leveraging innovative solutions, businesses can ensure that they remain competitive in an ever-changing market. The future of plastic extrusion holds exciting possibilities, paving the way for more efficient, sustainable, and high-quality production.

]]>Key Takeaways

- Extruded plastic profiles are vital in various industries such as automotive, medical, and construction, providing functionality and design versatility.

- Customization in plastic extrusion allows for tailored profiles that meet specific industry requirements, enhancing functionality and precision.

- The plastic extrusion process involves careful quality control and monitoring to ensure optimal performance, durability, and compliance with industry standards.

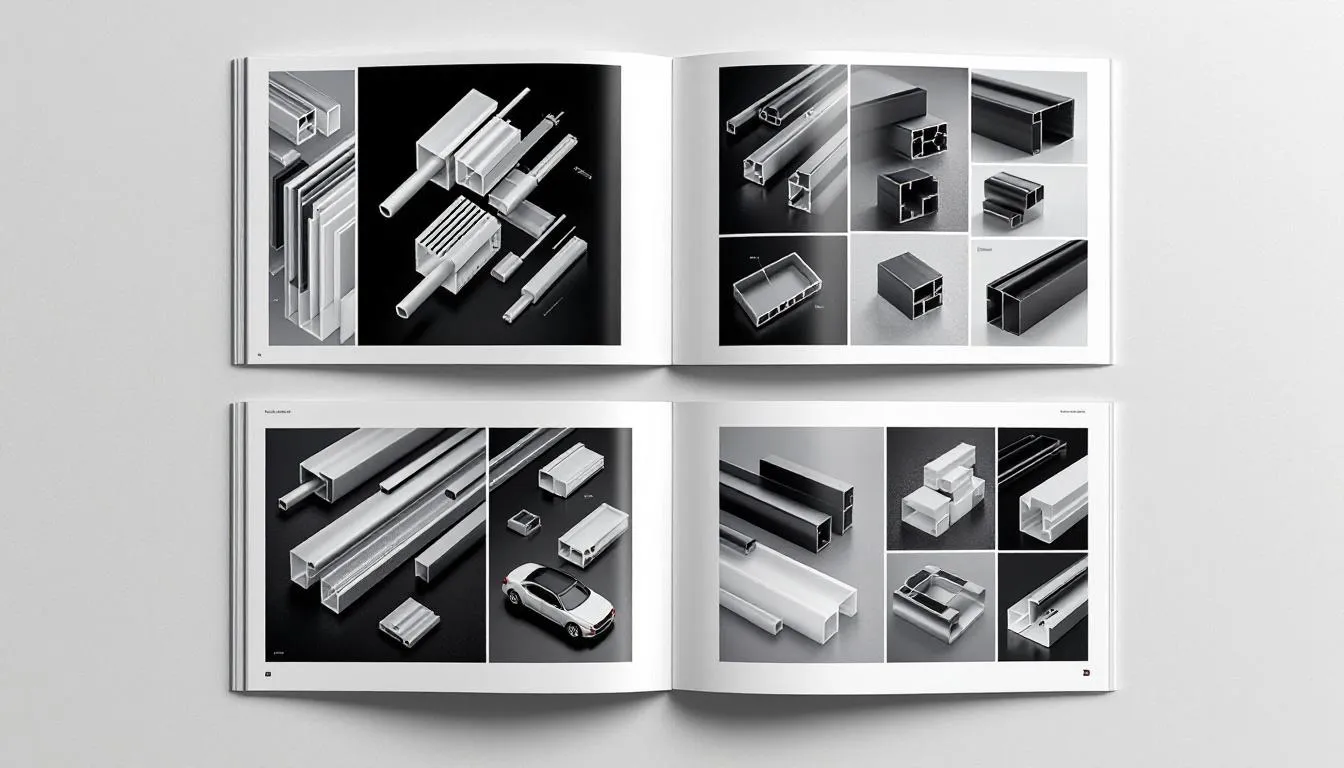

Overview of Extruded Plastic Profiles

Plastic extrusion is a high-volume manufacturing process that transforms raw plastic materials into continuous profiles, known as extruded plastic profiles and stock plastic extrusions. These profiles are indispensable in various industries, contributing significantly to manufacturing efficiency and versatility. From automotive parts to consumer goods, extruded plastic profiles are everywhere, enhancing both functionality and design.

The versatility of extruded plastic profiles is evident in their usage across diverse sectors:

- In the automotive industry, they are used for weather seals and interior trims.

- In the medical field, they form the backbone of tubing and catheters.

- Agricultural applications, consumer goods, and even solar panels benefit from the adaptability and durability of extruded plastic profiles.

The process allows for the manufacture of tailored shapes and manufactured components, ensuring that each profile meets specific industry requirements.

Common shapes of plastic profiles include:

- Thin films

- Rods

- Wire sheets

- Trims

- Channels

- Tubing

- Gaskets

These shapes are designed to meet the unique demands of their respective applications, providing durability, flexibility, and efficiency. Materials like polyacetal, acrylic, and nylon further expand the range of applications, making polymer plastic extrusion a versatile and invaluable process in modern manufacturing.

Types of Plastic Materials Used in Extrusion

The choice of plastic materials is crucial in plastic extrusion, as it determines the properties and applications of the final product. A variety of thermoplastic materials are utilized, including ABS, PVC, and polypropylene, each offering unique plastic material properties that cater to specific needs, including different viscous plastics. For instance, material selection is important, as PVC is known for its durability and resistance to environmental factors, making it ideal for construction and automotive applications.

Polyethylene, polypropylene, polyacetal, acrylic, nylon, polystyrene, ABS, polycarbonate, and acrylonitrile butadiene styrene are among the most commonly used materials in plastic extrusion. Each material brings its own set of advantages:

- Low density polyethylene: valued for its flexibility and resistance to chemicals.

- Polypropylene: offers high tensile strength and is used in a variety of industrial applications.

- Polycarbonate: known for its impact resistance and is often used in safety and electronic applications.

Bausano extruders, for instance, can process a wide range of materials, including PVC and HDPE, enhancing the possibilities for custom plastic extrusions. This capability allows manufacturers to select the best material for their specific application, ensuring optimal performance and durability.

Custom Plastic Extrusions

Customization in plastic extrusion is a game-changer, allowing manufacturers to design unique profiles that meet specific industry requirements. This capability is especially crucial for projects that demand tailored solutions. Whether it’s a complex automotive component or a specialized medical device, custom plastic extrusions can be meticulously designed to enhance functionality and fit precise application needs.

The ability to produce small, tailored batches efficiently has significantly improved with advancements in customization capabilities. This means that even niche applications can benefit from the precision and versatility of custom plastic extrusions. Options for additive customization, such as UV resistance, color matching, and flame retardance, further enhance the performance of these profiles in various environments.

Precision manufacturing is key in custom plastic extrusions. Tolerances for wall thicknesses can range from 0.030 inches to 0.375 inches, ensuring that each profile meets the exact specifications required for its application. This high degree of customization in shapes and sizes makes extruded plastic profiles indispensable for a wide range of industries.

The Plastic Extrusion Process

Plastic extrusion is a high-volume manufacturing process that transforms raw plastic materials into continuous profiles. The processed materials involve:

- Starting with raw plastic materials, typically in the form of granules, plastic pellets, pellet form, or powder.

- Feeding these materials into a heated chamber.

- Using a rotating screw to move the materials through the chamber.

- Gradually melting the materials through friction and applied heat in the plastics extrusion process.

The extrusion process involves the following steps:

- The temperature applied is carefully tailored to the specific type of plastic being used.

- As the plastic moves through the screw conveyor, it is sheared and heated, eventually becoming molten plastic.

- This molten plastic is then forced through a die, which shapes it into the desired profile extrusion by extruding it.

- The design of the die is crucial, as it ensures a smooth and consistent flow of melted plastic into the final product shape.

Cooling is an essential part of the extrusion process. Once the plastic exits the die, it must be cooled quickly to retain its shape. This can be done using air or water as the extruded plastic moves onto a conveyor belt. Cooling rolls may also be used to cool and size the extruded plastic immediately, ensuring precise internal and external dimensions.

Quality control is integral to the plastic extrusion process. It involves:

- Assessment of raw plastic materials to ensure their purity and integrity.

- Regular inspection of the extrusion die and screw to maintain proper material flow and pressure.

- Monitoring temperature, pressure, and speed during the extrusion process to guarantee consistent product quality.

Applications of Extruded Plastic Profiles

Extruded plastic profiles are used in a wide range of applications, thanks to their versatility and functionality. In the construction industry, extruded profiles contribute to the creation of weather-resistant and thermally efficient profiles used in windows and doors. These profiles help improve energy efficiency and durability in buildings, making them an essential component in modern construction.

The automotive industry relies heavily on extruded plastic profiles for various parts, especially those such as weather seals and interior trims. These other components are designed to withstand chemical and temperature variations, ensuring long-lasting performance.

In the medical field, plastic extrusion is key for producing rigid tubing and catheters, utilizing medical-grade plastics that comply with regulatory standards.

Extruded plastics also play a significant role in the packaging industry, where they are used to create plastic film and sheets of various thicknesses. These materials offer protective qualities that enhance product shelf life. Additionally, materials like polycarbonate and polystyrene are used in specialized applications, such as electronic housings and solar panel frames, further showcasing the versatility of extruded plastic profiles.

Advantages of Using Extruded Plastic Profiles

The advantages of using extruded plastic profiles are numerous. Their lightweight nature simplifies handling, transportation, and installation, leading to significant cost savings. Additionally, extrusion tooling is generally more economical and efficient compared to other plastic manufacturing methods.

Plastic extrusions are also known for their resistance to corrosion, chemicals, and moisture, making them suitable for harsh environments. The fabrication process is straightforward, allowing for efficient cutting, drilling, and assembly. Twin screw extruders, in particular, offer enhanced efficiency and energy-saving benefits, especially when handling materials with poor thermal stability.

Twin Screw Extruders vs. Single Screw Extruders

Twin screw extruders and single screw extruders each have their unique advantages and applications. The most common type of twin screw extruders are divided into two main types. These are co-rotating and counter-rotating extruders. They excel in blending and reactive extrusion due to their advanced mixing capabilities. Moreover, twin screw extruders have superior venting and self-cleaning functions compared to their single screw counterparts.

Single screw extruders, on the other hand, are simpler and less costly, making them suitable for basic applications. The E-GO Series one screw extruders, for example, are customizable in every detail with Digital Extruder Control 4.0, providing precision and efficiency for various plastic extrusion needs, including individual extruders delivering and a single extrusion head.

Co-extrusion Techniques

Co-extrusion is a technique that allows for the combination of multiple materials or colors in a single extrusion, providing both structural and aesthetic benefits. This method enables the fusion and layering of multiple layers to create a composite structure with enhanced properties. For instance, using different materials in co-extrusion can yield products with improved stiffness and resistance to heat.

However, co-extrusion also comes with its challenges. Not all plastics can be co-extruded due to compatibility issues, particularly with polymers that have differing melting points. Despite these challenges, plastic co extrusion remains a valuable technique for producing multilayer films or packaging that enhance product durability and strength.

Quality Assurance in Plastic Extrusion

Quality assurance is paramount in plastic extrusion to ensure that the final products meet desired technical and functional standards. Adhering to industry standards, such as ISO certifications, enhances the reliability and durability of extruded plastic profiles. Bausano, for instance, ensures maximum quality at the technical-functional level during the plastic extrusion process.

These quality control measures contribute to the overall excellence and durability of extruded plastic profiles. Monitoring parameters like temperature, pressure, and speed during the extrusion process ensures consistent product quality and performance.

Choosing the Right Plastic Extruder Manufacturer

Selecting the right plastic extruder manufacturer is crucial for ensuring high-quality production. A strong track record in the plastic extrusion industry is a key indicator of a manufacturer’s reliability. Evaluating the technology and equipment used by a manufacturer can significantly impact production precision and efficiency.

Good communication and after-sales support are essential for building a trustworthy supplier relationship. Customer feedback and references provide valuable insights into a supplier’s reliability and service quality. Additionally, on-time delivery performance is crucial for maintaining production schedules and avoiding disruptions.

Innovations in Plastic Extrusion Technology

The plastic extrusion industry is witnessing significant advancements, particularly with the integration of digital technologies. These innovations allow for real-time monitoring and predictive maintenance, enhancing efficiency and reducing downtime. Energy-efficient designs and advanced heating systems are being developed to reduce energy consumption in plastic extrusion processes, including those involving plastic extruders. The plastics industry is evolving rapidly, adapting to these new technologies.

Incorporating renewable energy sources is another innovative solutions practice being adopted to decrease reliance on fossil fuels. These developments are essential for lowering carbon emissions and promoting sustainability in plastic extrusion manufacturing.

Environmental Impact and Sustainability

The environmental impact of plastic extrusion processes is a significant consideration, given the materials used and energy consumed. Key points include:

- Utilizing recycled materials in extrusion processes can significantly reduce environmental impact.

- Co-extrusion techniques can incorporate recycled materials mixed with virgin plastics.

- These methods help reduce material costs and waste.

The plastic extrusion industry is increasingly moving towards a circular economy model by incorporating recycling technologies to minimize the need for new materials. Recent technological advancements, such as induction heating systems and recycling extruders, have enhanced sustainability in plastic extrusion.

Manufacturers are committed to reducing energy consumption and recovering plastic scrap material to lessen their environmental impact.

Summary

In summary, extruded plastic profiles are a cornerstone of modern manufacturing, offering versatility, efficiency, and customization. The high-volume manufacturing process, coupled with the wide range of materials available, makes plastic extrusion an invaluable technology across numerous industries. From construction to automotive, and medical to packaging, the applications are diverse and impactful.

As we move forward, innovations in plastic extrusion technology and a focus on sustainability will continue to shape the industry. By understanding the intricacies of the extrusion process and the benefits of custom plastic extrusions, manufacturers can leverage this technology to enhance their products and reduce their environmental footprint. The future of plastic extrusion is bright, promising continued advancements and sustainable practices.

]]>Key Takeaways

- Custom extruded plastic profiles are tailored solutions for various industries, including construction, automotive, and healthcare, offering versatility in design and application.

- The extrusion process involves careful material selection, precision shaping, and rigorous quality control to ensure that final products meet specific performance requirements.

- Recent advancements in co-extrusion and secondary operations enhance the functionality and customization of plastic profiles, making them indispensable in modern manufacturing.

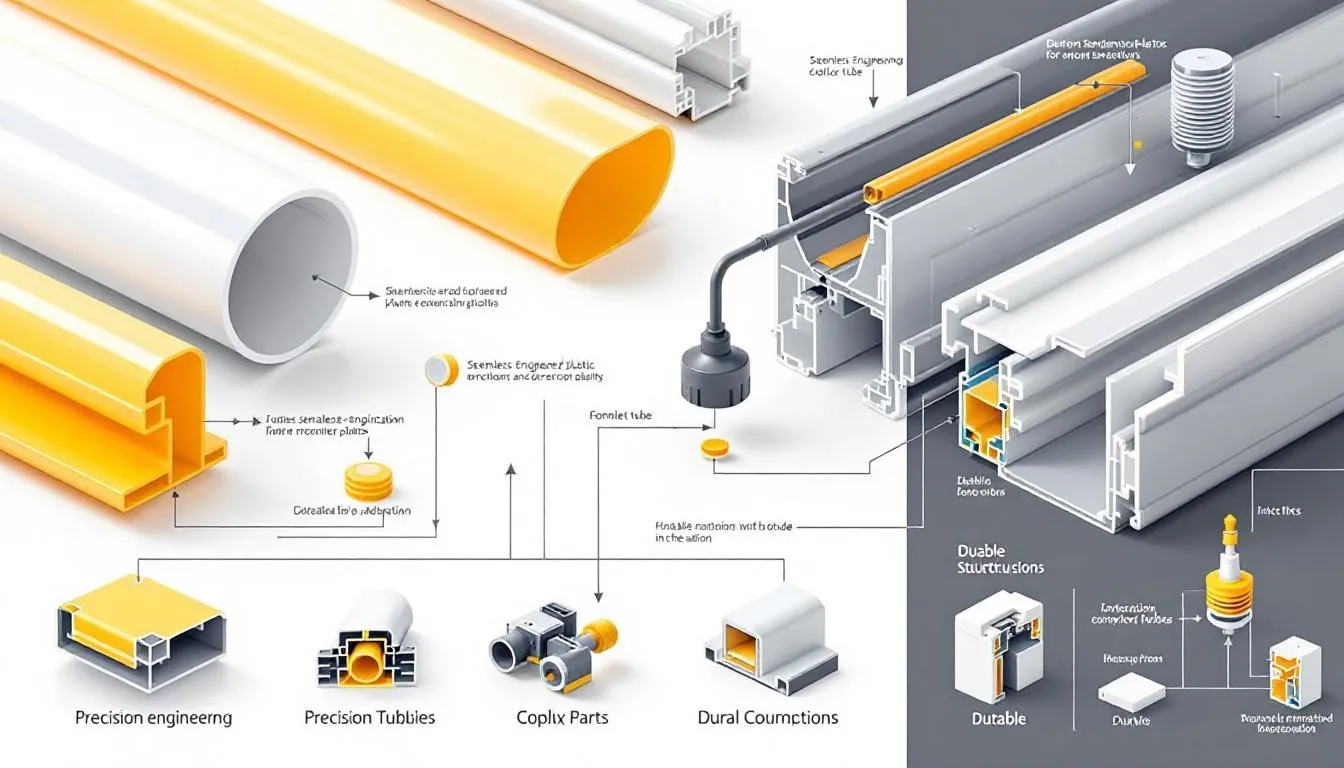

Understanding Custom Extruded Plastic Profiles

Custom plastic extrusions are engineered solutions designed to meet specific needs, whether it be unique geometries, complex interactions, or distinctive branding requirements. Unlike stock plastic extrusions, these custom profiles can be tailored to fit exact specifications, making them invaluable in a broad spectrum of applications.

These extruded plastic profiles find their purpose in various sectors:

- In the construction industry, they are used for components like window frames, siding, roofing, and drainage systems.

- In the automotive sector, they serve as trims, seals, and body side moldings.

- In healthcare, they are essential for medical tubing and surgical instruments.

The versatility and adaptability of custom plastic extrusions make them a flexible staple in modern manufacturing.

The Custom Plastic Profile Extrusion Process

The custom plastic profile extrusion process is a marvel of modern engineering, designed for the high-volume production of continuous shapes. This process involves melting plastic and shaping it into profiles that can be either solid or hollow. The precision of custom plastic extrusion allows for intricate designs and tight tolerances, opening up endless design possibilities.

During the extrusion process, in-line operations such as printing and adding tape can be incorporated, enhancing the functionality of the final product. Specialized services like rolling, where plastic film is shaped into tubes, showcase the versatility of this manufacturing processes technique.

Let’s dive deeper into the critical steps of this process, starting with the essential aspect of material selection.

Material Selection for Custom Profiles

Material selection is a pivotal step in the custom plastic extrusion process. The choice of material directly impacts the characteristics of the final product, such as:

- Strength

- Flexibility

- Chemical resistance Selecting thermoplastic materials that align with specific application requirements is essential, including:

- Fire resistance

- Chemical durability

This careful selection process ensures that the custom profiles meet exact specifications and perform well in their intended environments. Selecting the right material enhances the performance and durability of extruded plastic profiles, broadening their suitability for various applications.

Melting and Extruding Plastic Pellets

The journey of custom plastic extrusion continues with the melting and extrusion of plastic pellets. The process involves:

- Feeding plastic pellets into an extruder.

- Plasticizing or melting the pellets due to shear and heat generated by friction.

- Moving the molten plastic through the conveyor.

- Reaching the die, which shapes the molten plastic into the desired profile.

The precision of this process is crucial, as it ensures that the extruded plastic profiles meet the exact specifications required for their intended use. The ability to control the shape, size, and consistency of the profiles during the extrusion process is what makes custom plastic extrusion so versatile and effective.

Shaping and Cutting Extruded Profiles

Once the plastic has been extruded, the process includes:

- Cooling the plastic under water to solidify it before cutting to the desired length.

- Employing advanced techniques to ensure that the profiles are cooled and cut accurately, meeting precise specifications.

- Using operations like thermoforming and ultrasonic welding to further enhance the quality and functionality of the extruded profiles.

The final shaping and cutting processes are integral to producing high-quality custom plastic profiles that fit their intended applications perfectly. Whether it’s a simple tube or a complex, multi-faceted profile, these advanced methods ensure that each piece meets the highest standards of precision and quality.

Benefits of Custom Plastic Extrusions

Custom plastic extrusions offer a multitude of benefits that make them a preferred choice across various industries. One of the most significant advantages is cost-effectiveness:

- High-volume production with custom plastic extrusion is economical due to the continuous operation after die setup.

- It minimizes material waste.

- It reduces overall costs.

This makes it an ideal solution for both custom and large scale production high-volume needs.

Moreover, the material properties of custom plastic extrusions can be tailored to enhance product performance. For instance, adding UV protection or flame retardants can significantly improve the durability and functionality of the final product. Techniques like foamed extrusion create lightweight materials with improved insulation properties, further expanding the applications of custom plastic extrusions.

These benefits, combined with the ability to produce intricate shapes and designs, make custom plastic extrusions a versatile and valuable manufacturing solution.

Innovations in Plastic Co-Extrusion

Plastic co-extrusion is an innovative process that allows for the simultaneous extrusion of multiple materials, resulting in products with enhanced features such as improved barrier properties. Recent advancements in co-extrusion technology and plastic extrusion technologies have enabled manufacturers to produce components with precise control over material layers, enhancing the functionality and performance of custom profiles.

One of the most exciting developments in this field is the integration of 3D printing with co-extrusion, which is revolutionizing prototype development and production capabilities. This combination allows for rapid prototyping and the creation of complex designs that were previously unattainable.

Common applications of plastic co-extrusion include edge trims, seals, and dual-durometer products, which benefit from the enhanced properties provided by co-extrusion technology. Plastic co-extrusion is particularly useful in sectors such as automotive interiors, retail displays, and specialty packaging. By increasing the functionality of custom profiles, co-extrusion offers innovative solutions that meet the evolving needs of various industries.

Custom Plastic Tubing Solutions

Customization in plastic tubing allows manufacturers to tailor products to specific design and functional requirements, enhancing their usability. Factors that can be adjusted include:

- Material choice

- Flexibility

- Wall thicknesses

- Specific coatings

This customization ensures that the tubing performs optimally in its intended application.

The performance of plastic tubing can also be adjusted based on its diameter and wall thickness, allowing for tailored applications in various industries. Manufacturers can produce tubing in various shapes, including round and square, to meet specific needs. This flexibility in design and functionality makes custom plastic tubing a versatile solution for many applications.

Industries Utilizing Custom Extruded Plastic Profiles

Custom extruded plastic profiles are essential across a wide range of industries, including:

- Construction sector: used for window frames, siding, and roofing components

- Automotive industry: used for parts like trims, seals, and body side moldings

- Healthcare applications: include medical tubing and surgical instruments, where precision and reliability are paramount

Other industries that utilize custom plastic extrusions include:

- The electrical sector for cable management systems

- Agriculture for irrigation components

- The packaging industry for containers and films

- The marine industry for corrosion-resistant components like boat fenders

- Furniture production for edge banding and shelving systems, along with other components.

The versatility of custom plastic extrusions makes them indispensable in modern manufacturing, especially when considering the benefits of PVC.

Quality Control in Plastic Profile Extrusion

Quality control is a critical aspect of the plastic profile extrusion process. Rigorous testing of raw materials and final products ensures that the extrusions meet the highest standards of integrity and performance. Initial assessments of raw plastic materials focus on verifying their purity and integrity, which is crucial for consistent extrusion results.

Throughout the extrusion process, parameters such as temperature, pressure, and speed are continuously monitored to maintain uniform quality. Vacuum calibration is employed to cool and size extruded profiles accurately right after they exit the die.

Final inspections assess properties like color consistency, dimensional stability, and tensile strength, ensuring that the extruded plastic profiles provide adequate structural support and meet the required specifications.

Custom Fabrication and Secondary Operations

Beyond the initial extrusion process, custom plastic profiles often undergo secondary operations to enhance their functionality and usability. These processes can include heat treating, printing, labeling, welding, anodizing, and electroplating. Secondary operations such as notching, drilling, gluing, taping, punching, forming, and heat welding are also available, allowing for further customization.

Selecting a manufacturer that offers these in-house tooling secondary operations can be highly beneficial, as it ensures that the extruded products can be used as-is or fabricated into more complex assemblies that are manufactured. This capability is particularly valuable for projects that require precise customization and assembly, as it streamlines the production process and reduces the need for additional suppliers.

Choosing the Right Custom Plastic Extrusion Manufacturer

Choosing the right custom plastic extrusion manufacturer is crucial to the success of your project. The right manufacturer will:

- Have decades of design, engineering, and manufacturing experience to ensure quality and reliability.

- Possess the capabilities to meet specific application requirements.

- Provide the necessary support throughout the project.

Choosing the wrong manufacturer can lead to product failures, increased costs, and wasted time on rework. Companies like SeaGate Plastics offer cost-effective custom plastic extrusions with quick turnaround times, making them a reliable choice for your extrusion needs.

Ready to Start Your Custom Extrusion Project?

Starting a custom extrusion project is easier than ever. Businesses can upload CAD files to receive instant quotes, ensuring a smooth and efficient start to their projects. Sample parts are provided for approval before full production commences, guaranteeing client satisfaction and alignment with project requirements.

Expert consultation is available to ensure that specifications align with project needs, and services such as custom color matching and packaging design enhance the presentation and marketability of extruded products. Custom plastic extrusion services are offered at competitive prices, especially for high-volume needs.

Summary

Custom extruded plastic profiles offer a versatile and cost-effective solution for a wide range of applications. From the initial material selection to the final product, the extrusion process allows for precise customization and high-volume production. Innovations in co-extrusion and secondary operations further enhance the functionality and usability of these products.

By choosing the right manufacturer and leveraging the benefits of custom plastic extrusions, businesses can achieve their design and functional goals with efficiency and reliability. Whether you’re in construction, automotive, healthcare, or any other industry, custom extruded plastic profiles provide tailored solutions that meet your specific needs.

]]>Key Takeaways

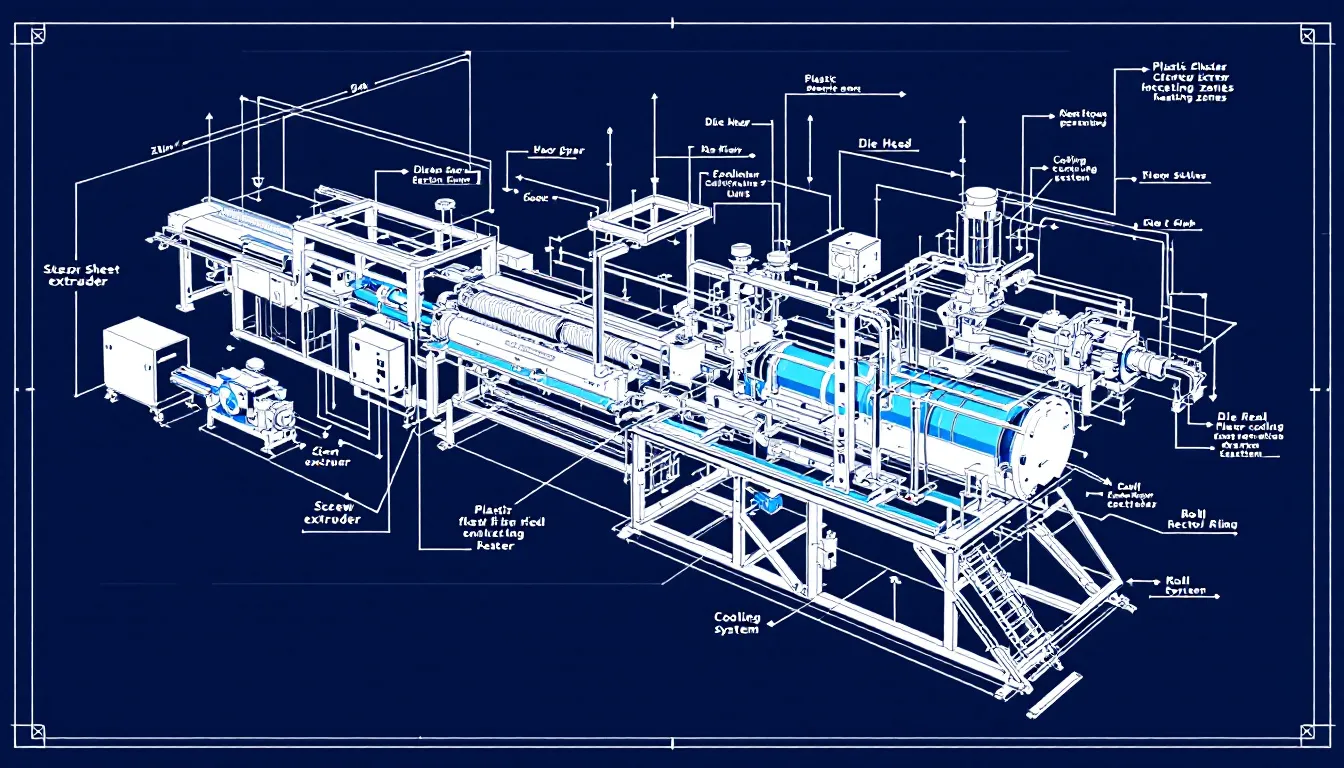

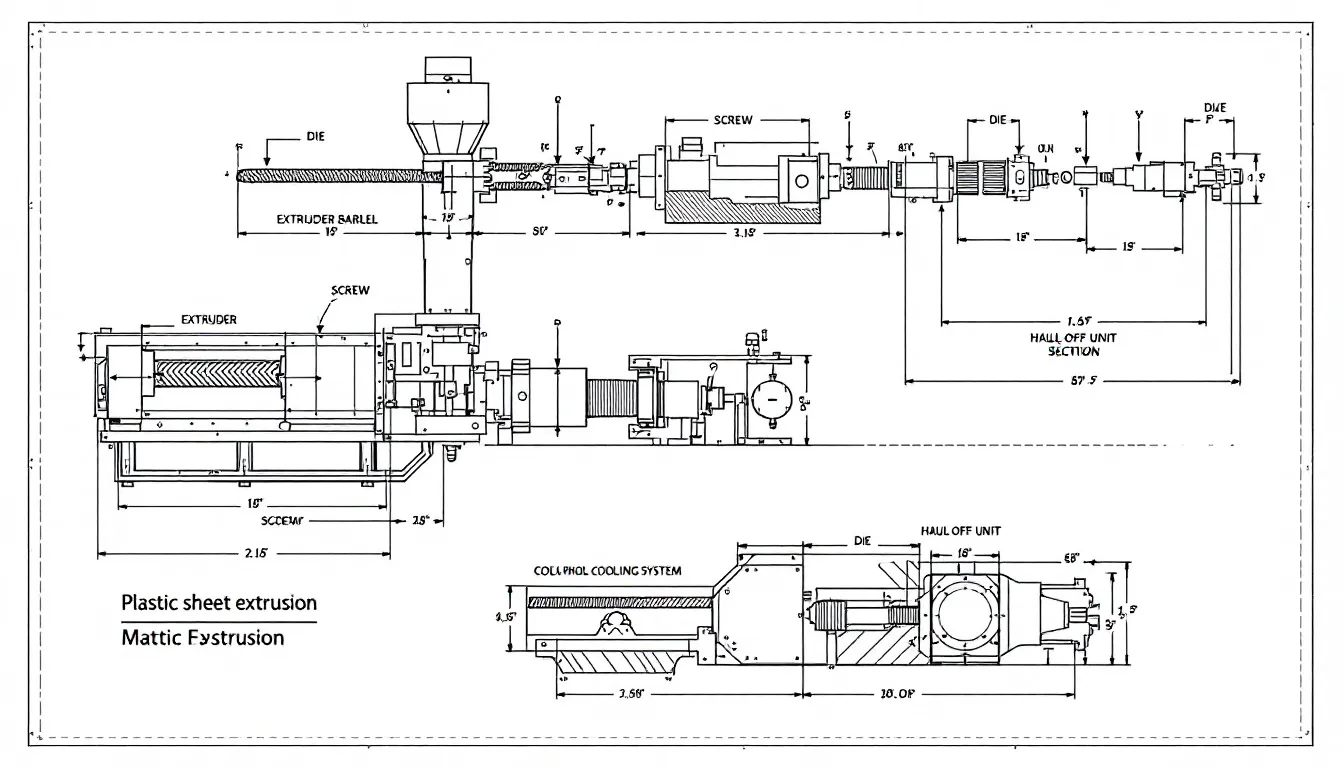

- Key components of a plastic sheet extruder machine include the extruder, die head, cooling rolls, and control system, each essential for high-quality production.

- Types of extruders—single screw and twin screw—offer different advantages, with single screws favored for simplicity and reliability, while twin screws excel in material mixing.

- Choosing the right materials, such as PET, PP, and PC, is vital for the quality and performance of extruded plastic sheets, impacting their applications across industries.

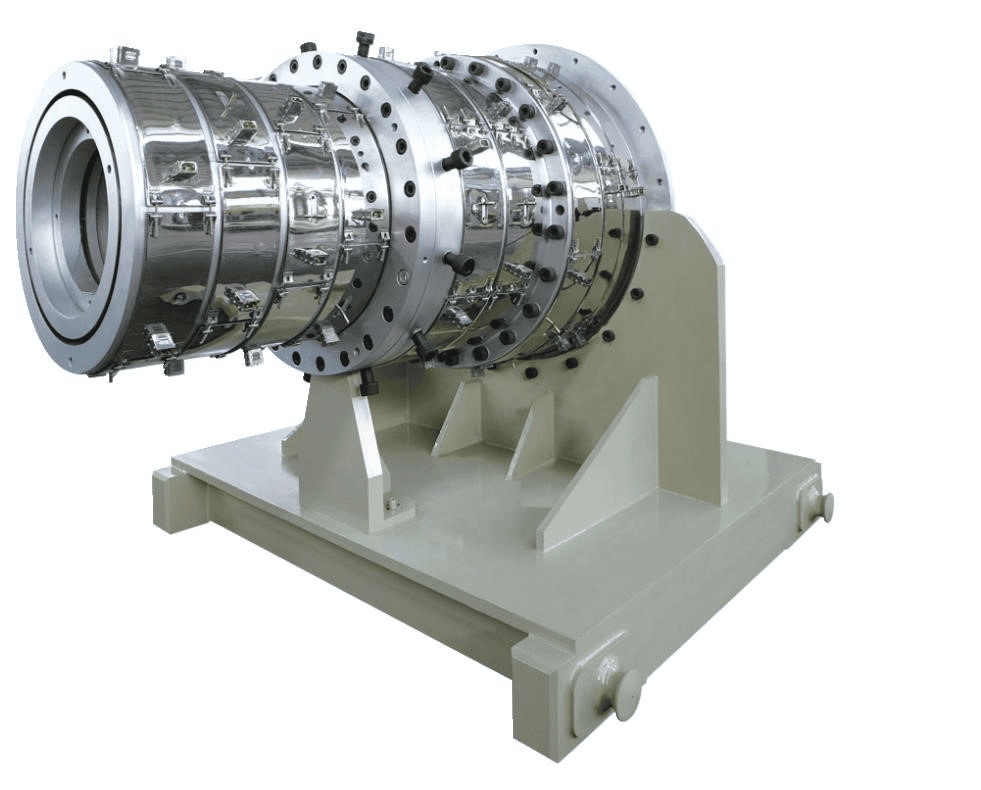

Key Components of a Plastic Sheet Extruder Machine

Grasping the key components of a plastic sheet extruder machine is essential for those in the manufacturing process. The main parts include:

- The extruder

- Die head

- Cooling rolls

- The control system Each integral to producing high-quality plastic sheets.

These individual components work in harmony to melt, shape, and solidify plastic materials, ensuring consistency and precision in the final product.

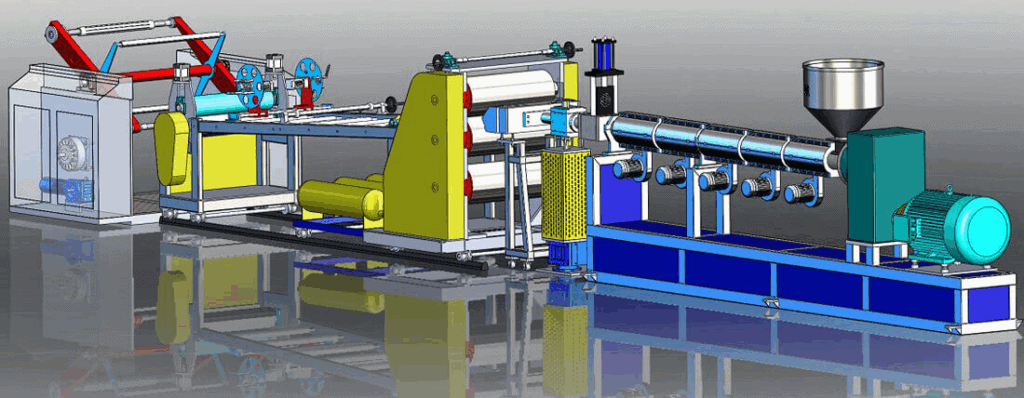

The Extruder

The extruder is the core of the plastic sheet extrusion process, tasked with:

- Melting and homogenizing plastic materials.

- Utilizing rotating screws to blend the plastic uniformly, ensuring a consistent flow of molten plastic.

- Mixing and transporting the material.

- Generating the needed heat for melting.

Whether using single or twin screws, the efficiency and reliability of several extruders are critical for producing high-quality plastic sheets.

Die Head

The die head is where the magic happens, shaping the molten plastic into sheets with precise thickness. In sheet extrusion, T-shaped, coat-hanger dies, and flat dies are commonly used to achieve the necessary sheet profiles. However, improper die design can lead to clogging issues, impacting the final product’s quality.

Therefore, meticulous attention to die head design is crucial for optimal performance.

Cooling Rolls

Cooling rolls are critical in the plastic sheet extrusion process, playing a vital role in solidifying the extruded material. They maintain a uniform temperature, ensuring that the plastic sheets cool evenly and retain their intended shape and properties.

Effective temperature control via cooling rolls is vital for producing high-quality plastic sheets.

Control System

The control system is the brain of the plastic sheet extruder machine, managing critical parameters such as temperature and speed. Precise management of these parameters ensures the consistent quality of the extruded sheets.

Maintaining optimal conditions throughout the extrusion process, the control system is pivotal in achieving high production efficiency and product quality.

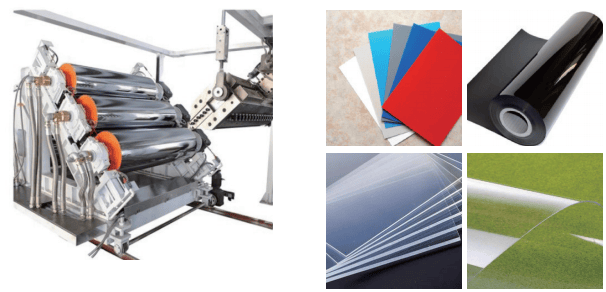

Types of Plastic Sheet Extruder Machines

Plastic sheet extruder machines come in various types, with single screw and twin screw extruders being the most common. Each type has its unique advantages and is suited for different applications. Recognizing these differences helps in selecting the right machine for your specific needs, be it simplicity and ease of operation or advanced mixing capabilities.

Single Screw Extrusion Machines

Single screw extrusion machines are renowned for their simplicity and reliability. They are widely used in plastic sheet production due to their straightforward one screw operating and maintenance.

Industries ranging from food packaging to automotive benefit from the versatility of these machines, making them a staple in many manufacturing processes. Their design allows for efficient processing of various plastic materials, ensuring consistent product quality.

Twin Screw Extrusion Machines

Twin screw extrusion machines offer superior mixing capabilities, making them ideal for processing complex materials. They come in two sub-types: co-rotating and counter-rotating, each with specific advantages.

While co-rotating extruders provide excellent ingredient uniformity, counter-rotating extruders can handle higher pressure build-up, enhancing operational efficiency. These machines are essential for applications requiring precise material blending and high-quality outputs through coextrusion.

Materials Used in Plastic Sheet Extrusion

Choosing the right materials for plastic sheet extrusion is critical for achieving the desired properties in the final product. Common materials include polyethylene (PE), polypropylene (PP), and polycarbonate (PC), each offering unique benefits.

The choice of material impacts not only the extrusion process but also the performance and durability of the plastic sheets.

Polyethylene Terephthalate (PET)

Polyethylene Terephthalate (PET) is a thermoplastic polymer widely used in plastic sheet production due to its excellent strength, thermal stability, and chemical resistance. Its versatility makes it a preferred choice for various applications, including packaging, automotive components, and medical devices.

PET’s performance in extrusion processes highlights its essential role in manufacturing high-quality plastic sheets.

Polypropylene (PP)

Polypropylene (PP) is a highly versatile material used in numerous industrial applications. Its strength increases with higher ethylene content in its copolymer forms, making it ideal for automotive and industrial sectors.

PP’s robustness and resistance to chemicals and moisture make it a valuable material in plastic sheet extrusion.

Polycarbonate (PC)

Polycarbonate (PC) is renowned for its impact resistance, making it suitable for protective barriers and high-stress applications. Industries benefit from PC’s ability to produce high-quality sheets that can withstand significant physical stress, ensuring durability and reliability in various industrial applications.

The Plastic Sheet Extrusion Process

The plastic sheet extrusion process is a meticulous sequence of steps that transform raw materials into high-quality processed plastic sheets, with further processing involved. It begins with feeding raw materials into the extruder, followed by melting and mixing, and culminates in shaping and cooling the molten plastic using plastic sheet extrusion lines.

Each step is critical for ensuring the consistency and quality of the final product.

Feeding Raw Materials

The journey of plastic sheet extrusion begins with the introduction of raw materials. These materials:

- They are usually in pellet or plastic granule form

- Are fed into the extruder

- They are introduced through a hopper

- They are transported to the feed zone, where they begin to melt and mix.

Proper feeding is essential for maintaining a consistent flow and quality of the final product.

Melting and Mixing

Once in the extruder, the raw materials are gradually melted and homogenized using a rotating screw in a heated cylinder. The mechanical energy generated by the screws helps achieve the desired consistency and flow characteristics of the molten plastic.

Maintaining optimal thermal properties and temperature control is critical for ensuring a smooth and efficient extrusion process.

Shaping and Cooling

The molten plastic is then forced through a die, shaping it into continuous sheets. Cooling rolls rapidly cooled the shaped material, solidifying it into the desired form through injection molding.

Effective temperature control during this phase is essential for preventing warping and ensuring uniform thickness and texture in the final product.

Optimizing Plastic Sheet Extrusion

Optimizing the plastic sheet extrusion process is key to enhancing production efficiency and product quality. Manufacturers can employ various strategies, including:

- Equipment adjustments

- Process parameter tuning

- Material selection improvements. These optimizations ensure consistent product quality and reduce operational costs.

Equipment Adjustments

Regular maintenance and adjustments of plastic sheet extruder machines are key to optimal performance. Scheduled checks help identify potential issues before they escalate, ensuring longevity and consistent operation.

Adjusting machine settings, such as screw configurations and temperature controls, can significantly improve throughput and product quality.

Process Parameter Tuning

Fine-tuning process parameters like temperature and screw speed is crucial for optimizing the efficiency and quality of plastic sheet extrusion. Advanced technologies and detailed analyses can identify inefficiencies and opportunities for enhancement, leading to better product consistency and overall process efficiency.

Material Selection Improvements

Selecting the right plastic materials is fundamental to improving the extrusion process and the final product’s performance. Proper plastic material selection minimizes issues related to inconsistent raw materials, ensuring high-quality outputs.

Commonly used materials like PET, PP, and PC offer specific properties that enhance the extrusion process and meet various application needs.

Common Challenges in Plastic Sheet Extrusion

Plastic sheet extrusion is not without its challenges. Issues such as temperature control, screw speed, air pressure adjustments, and pressure adjustments can affect the quality and consistency of the final product.

Addressing these challenges through effective management and optimization strategies is key to producing high-quality plastic sheets.

Material Inconsistencies

Inconsistent raw materials can lead to significant product defects, including surface imperfections and improper thickness. Implementing strict quality control measures and sourcing materials from reputable suppliers can help manage these inconsistencies.

Advanced blending techniques also help ensure consistent product quality.

Die Clogging

Die clogging is a common issue that can disrupt the flow during the extrusion process, leading to uneven thickness or defects in the final product. Using appropriate filters and maintaining the die head can help mitigate this problem, ensuring a smooth and consistent extrusion process.

Cooling Issues

Effective cooling is crucial for preventing defects like warping and maintaining the quality of extruded plastic sheets. Proper temperature control and cooling management ensure uniform thickness and texture, resulting in high-quality final products.

Manufacturers must prioritize cooling systems to achieve consistent and reliable outputs.

Applications of Plastic Sheets

Plastic sheets are integral to a wide range of industries, from automotive to food packaging and medical devices. Their versatility and adaptability make them essential in manufacturing processes, providing solutions that meet specific industry requirements.

The following subsections explore some of the key applications of plastic sheets.

Automotive Industry

In the automotive industry, plastic sheets are widely used to manufacture various automotive parts and components. Extruded sheets are specifically utilized for dashboards, protective panels, and other interior elements.

Polypropylene, in particular, is highly valued for its strength and durability, making it an ideal choice for vehicle interiors and other high-stress applications.

Food Packaging

Plastic sheets, especially those made from PET, play a crucial role in food packaging, providing durable and safe solutions for storing and transporting food products. These plastic sheets can be produced from both virgin and recycled materials, enhancing their sustainability and reducing environmental impact.

Their clarity and strength make them ideal for forming trays, lids, and flexible packaging.

Medical Devices

The use of plastic sheets in medical devices is essential for ensuring product sterility and safety. These sheets are designed to withstand chemical exposure and are easy to clean, making them suitable for a variety of medical applications.

Their role in the production of medical devices highlights their importance in maintaining high standards of hygiene and effectiveness.

Factors to Consider When Choosing a Plastic Sheet Extruder Machine

Selecting the right plastic sheet extruder machine is crucial for optimizing production efficiency and product quality. Key factors to consider include the manufacturer’s reputation, customization options, and energy consumption.

These considerations ensure that the chosen machine meets specific production requirements and supports sustainable manufacturing practices.

Manufacturer Reputation

Choosing a reputable manufacturer is critical for ensuring the reliability and performance of plastic extrusion machines. Evaluating customer feedback and case studies can provide insights into a manufacturer’s service quality and reliability.

Well-regarded brands like Davis-Standard are known for their high-quality equipment and exceptional support, making them a preferred choice in the industry.

Customization Options

Customization options are essential for meeting specific production requirements in plastic sheet extrusion. Features such as adjustable sheet thickness, texture, and color allow manufacturers to produce sheets tailored to their needs.

Companies like Bixby International and Reifenhäuser Group offer customized sheet production lines, ensuring versatility and adaptability in various applications.

Energy Consumption

Energy efficiency is a critical factor in plastic sheet extrusion, influencing operational costs and environmental sustainability. Energy-efficient machines reduce the carbon footprint and promote greener production practices.