Do you want to know how these reliable and flawless plastic products are formed? If yes, then you are on the right blog. Sheet extruder machines could be the answer you were searching for. These machines convert the specific materials to smooth and uniform sheets in a timely and cost-efficient manner.

Moreover, in today’s fast-moving plastic processing era, modern extrusion technology produces very efficient, cost-effective and durable products. In this blog, you will explore what a sheet extruder machine is, its working principle, types and industrial use, and some more points. So, stay connected!

1) What Is a Sheet Extruder Machine?

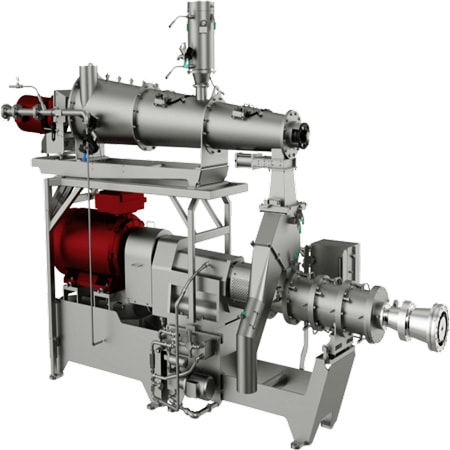

“A sheet extruder machine is an industrial machine designed to manufacture flat plastic sheets by melting raw plastic materials such as pellets or granules, then forcing the melted plastic through a flat die.”

Well, solid plastic pellets are used in machines, and then heat and pressure are applied through a flat die to form a desired product. However, this mechanism generates plastic sheets which are smooth and uniform in thickness, and they can be further processed by cutting and shaping.

Common Plastic Materials Used

In these machines, materials are used, such as PVC, PET, and polyethene. You know each of these has different characteristics: some are strong, some are flexible, some are clear, and others are opaque.

Why It Matters

If you are a manufacturer of automotive parts, curtain walls or food products, or you are a product designer, you have to know that sheet extruder machines tend to produce reliable, quality and cost-saving products. Thus, these plastic extruder machines save you time and resources when you are in need of strong and flexible materials.

2) Key Components of a Sheet Extruder Machine

Honestly speaking, if you know the key components of a sheet extruder machine, then you will easily understand how this machine functions properly. Let’s discuss key components of this machine, so get in touch!

i) Hopper

Well, the process begins in the hopper, which stores the raw plastic and gradually releases it while preventing backups.

ii) Screw and Barrel

Most importantly, the component of the extruder machine which does the heavy work is the screw and barrel. However, they heat, mix and ‘push’ the plastic forward, which is also where the plastic solids begin the melting process. Moreover, there are variety of screw diameters that are used to control the melting rate and flow of material.

iii) Compression Section

Another significant component is the compression section. While the plastic is trying to move forward, the compression section gradually increases its pressure. This is done to maintain an even melting state and to prepare the plastic for the next phase. Furthermore, this section is important to handle the complex shapes.

iv) Outlet/Die

Significantly, the die component is referred to as the forming tool. However, the products of specific shapes are formed like the plastic into a broad, thin sheet. Thus, this part finalises the end width, thickness and customization options for your product.

v) Cooling System

The system of cooling rollers cools the sheet, bringing it to a solid state while providing a strong form. Such a step is important in keeping the desired shape after cooling. Thus, this system is important for film extrusion.

vi) Drive System

Lastly, the virtually mechanical part of the system allows the screw to rotate while also controlling its speed. Such a factor impacts the system’s speed as well as the quality of the final product.

To put this discussion together, all the components contribute to the reliability, efficiency, and importance of sheet extruder machines in the production of plastic sheets.

3) Working Principle of Sheet Extruder Machines

Alright! The working principle is the heart of this blog. Let’s talk about how sheet extruder machines convert raw material into fine plastic. It seems difficult, but it is too easy a working principle:

Step 1) Feeding and Melting

The first and foremost step is that the plastic pellets are fed into the hopper. The hopper then introduces them to a rotating screw that’s located in a heated barrel. Through the rotation, the screw pushes the plastic forward, and simultaneously heat melts it.

Then, the screw creates friction, which in turn speeds up the melting process. At this stage, you can also add colour and other custom materials to the plastic.

Step 2) Shaping the Sheet

After the plastic is melted, it converts into a flat die. Well, the die is the heart of the extrusion machine since it gives the plastic its shape, width, and thickness. Then, a pure plastic is produced from the die in a single, continuous and uniform strip.

Step 3) Cooling and Solidifying

Subsequently, the hot plastic sheets cool down. However, they are either cooled via rollers or exposed to air or water, which helps them harden in a uniform manner.

Step 4) Cutting and Finishing

Lastly, the sheet is cut into the required sizes. After the cut, it can either be used in the current step or further processed in subsequent steps. Then, it is okay to use for automotive parts, architectural profiles or food processing sectors.

4) Types of Sheet Extruder Machines

You know different tasks are done with different types of sheet extruder machines. Let’s discuss the three major types and describe each individually.

i) Single-Screw Extruders

Well, single-screw extruders are the oldest and most basic types of extruding machines. However, single screw extrusion machines utilise one screw to convey and melt the plastic. The good thing is that this type is well-suited for basic operations, such as manufacturing simple plastic sheets.

Moreover, this model is inexpensive, reliable, and trouble-free to service and is suited for operations that do not have specialised requirements.

ii) Twin-Screw Extruders

Twin screw extrusion machines are best for greater control of the process and better mixing. They utilise two screws, and both rotate in the same direction.

Moreover, this configuration provides better mixing, which makes it ideal for operations involving fillers, additives, or colour changes. Thus, It is suitable for advanced customised sheet production.

iii) Series Extrusion Machines

Lastly, the series extrusion machines are used more often when the raw material is partially processed. For example, they can convert extruded foam melts into finished sheets like PE foam. This is a convenient method, as it reduces environmental impact and material recycling is possible.

To put it simply, each type of sheet extrusion machine is designed for a particular function. Thus, the right selection is made for the machine based on the material and the intended use.

5) Applications of Sheet Extruder Machines

Alright! Sheet extruder machines have a wide variety of applications in the industry. The broad use of such machines is due to their ability to manufacture strong and smooth sheets for various purposes. Let’s talk about some applications:

- Plastic Industry

Most importantly, these machines are made for the production of plastic sheets for packaging as well as construction materials and thermoformed products. Moreover, they are applicable in food containers and trays, as well as wall panels. Furthermore, they are useful for fast and reliable production of uniform, excellent products.

- Foam Production

Significantly, in the manufacturing of foam, especially PE foam sheets, plastic extrusion machines are very important. You know, in series extrusion machine processes, the foam melts into sheets that are light and flexible and used for padding and insulation, among other things.

- Medical and Technical Uses

Another application of this machine is in medical and technical uses. Well, certain industries require uniform and exact dimensions for the sheets.

You know accuracy is very important for the manufacturing of medical and laboratory equipment. Thus, plastics which are required for medical and technical use should be clean, high-grade plastics. Thus, these machines provide the precision needed for such applications.

In simple words, sheet extruder machines simplify production processes from everyday packaging to more complex technical tools, making them easier, faster, and more efficient.

6) Advantages of Using Sheet Extruder Machines

Well, there are several advantages when using sheet extruder machines in your production processes. Now, let’s explore the key reasons that enhance efficiency.

+ Fast and Cost-Effective: Well, the first and foremost advantage of using a sheet extruder machine is that they are fast and cost-effective. It is because it allows the production of large quantities of plastic sheets in a shorter amount of time. Moreover, this reduces the amount of time and money spent, especially for bulk orders.

+ Consistent Quality: Most importantly, uniform consistency is achieved when every sheet is produced with the same thickness and smooth finish. Thus, this results in fewer errors, making the production more efficient while improving waste management.

+ Flexible and Versatile: Sheet extruder machines are able to work with a broad variety of materials, including PET, PVC, and PE. Therefore, this makes it easier to produce packaging, foam, or even parts for industrial machinery.

+ Easy to Automate: Finally, fewer delays and a less manual workload make it easier to use these machines with automated systems. Thus, this helps with running longer workloads without constant monitoring.

7) Challenges and Solutions

To be honest, even though these machines are very productive, they may present some challenges. The good news is that the solutions to these challenges are often very simple and straightforward. Let’s start the discussion:

! Screw Wear: The screw of an extruder machine may wear out with time. Then, this may affect mixing and flow. Therefore, regular washing and preventative maintenance are very important; they help smooth operations.

! Material Degradation: Keep in mind, excessive temperature may cause burning or degradation of quality. Therefore, precise temperature control helps maintain these materials.

! Feeding Blockages: You have to know that material may sometimes assemble in the feeding section. This is most likely to occur with an insufficiently warm temperature or insufficiently consistent feed. Thus, appropriate feeding temperature and regulation of consistent flow may help eliminate these risks.

! Uneven Sheet Thickness: Lastly, if the final sheet is not as smooth as desired, the sheet calibration requires further adjustments. Such systems enhance quality in real time and thus provide automated monitoring and adjustment while actively enhancing the process.

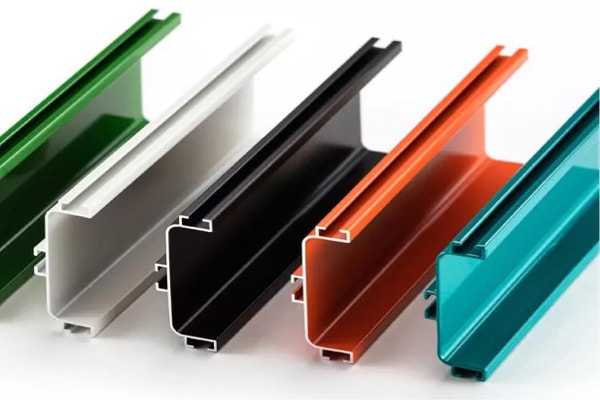

8) Faygo Union’s Custom Plastic Extrusion Services

Alright! Faygo Union provides reliable and custom extrusion services to help maintain extrusion specifications with quality and accuracy in focus. Let’s dive into the discussion:

- Expert Material Handling

First, plastic extrusion and aluminium profiles are our specialisation. You provide the design, and we help shape it into a custom part.

- Fast Prototyping & Short Runs

Significantly, fast production of prototypes and small quantities is done with modern machinery. Such rapid manufacturing enables testing and refining designs within days.

- Precision & Quality

In addition to the initial inspection, a thorough examination is performed on every component. The checks performed guarantee that the shape, size, and strength of the parts function perfectly for your requirements.

- Complete Support

In addition, we walk you through the steps of material selection and process configuration. This helps in obtaining the exact part needed for the project.

To be honest, Faygo Union has over two decade of experience and has completed over thirty thousand custom projects. Our blend of speed and quality, along with exceptional customer support, makes us a preferred provider of plastic extrusion equipment.

9) Conclusion

Alright! The importance of sheet extruder machines in manufacturing high-quality plastic sheets for different industries cannot be overlooked. The capability of achieving consistent output and the ability to shift to different materials make them indispensable in modern manufacturing.

However, if your priority is efficiency, safety and sustainability, then your production becomes future-ready. For those wanting to change their sheet extrusion process, Faygo Union provides excellent custom extrusion services with fast response times and good precision. Thus, Faygo Union will be a valuable partner for reliable and efficient sheet extrusion.

You can contact us right now by clicking here.