Automated Guided Vehicles (AGVs) are revolutionizing industries by automating the transport of materials within controlled environments. These self-driving vehicles navigate without human operators, making them a game-changer in various sectors, including manufacturing, logistics, and warehousing. AGVs not only enhance operational efficiency but also contribute significantly to safety and productivity improvements. In this article, we’ll dive into AGV fundamentals, types, navigation systems, benefits, and their diverse applications.

What is an Automated Guided Vehicle (AGV)?

An Automated Guided Vehicle (AGV) is a mobile robot that autonomously transports materials or goods within a predefined environment. Unlike traditional vehicles, AGVs operate without a human driver. They are widely used in large facilities like factories and warehouses to transport heavy loads efficiently and reliably. AGVs are essential components of automated production lines, helping businesses achieve higher operational speeds while reducing labor costs.

Brief History of AGVs

The concept of AGVs dates back to the mid-20th century, where they were initially employed to speed up material handling in warehouses and production centers. Early AGVs relied on wire-based navigation systems, but as technology evolved, so did AGVs. Modern AGVs now use advanced navigation technologies like laser guidance, machine vision, and sensors to navigate complex environments autonomously.

The Importance of AGVs in Modern Production Lines

In today’s fast-paced industrial world, AGVs play a pivotal role in increasing production efficiency. By automating the transport of goods and materials, AGVs minimize human intervention, reduce errors, and optimize workflows. They also improve safety by removing the risks associated with human-operated machinery and by reducing workplace accidents. AGVs contribute to a streamlined supply chain by operating continuously, enabling round-the-clock productivity.

Types of Automated Guided Vehicles (AGVs)

AGVs come in various configurations to meet the needs of different industries. The most common types include:

- Automated Guided Carts (AGCs)

- These are simple AGVs that typically follow predefined paths, such as magnetic tracks or wire-guided routes. AGCs are suitable for moving smaller loads and are commonly used in manufacturing and warehousing.

- Forklift AGVs

- Designed to mimic traditional forklifts, these AGVs can lift and transport materials at various heights without the need for a human operator. Forklift AGVs are commonly used in large-scale warehouses and manufacturing facilities.

- Unit Load AGVs

- These vehicles are designed to carry unit loads, such as pallets or containers. With platforms or forks, unit load AGVs can transport substantial goods from one point to another in industries like logistics and warehousing.

- Towing AGVs (Tuggers)

- Towing AGVs are used to pull carts, trailers, or other wheeled devices autonomously. These AGVs are designed to tow materials across long distances, making them ideal for transporting bulk goods.

- Heavy Burden Carriers

- Built to handle heavy-duty loads, these AGVs are equipped with advanced steering options and often feature self-loading capabilities. Heavy burden carriers are commonly used in manufacturing and logistics environments that require robust material handling.

- Hybrid AGVs

- Hybrid AGVs offer both autonomous and manual operation. These versatile vehicles can switch between automatic navigation and manual control, providing flexibility for operations that need a human touch in certain scenarios.

- Autonomous Mobile Robots (AMRs)

- Though similar to AGVs, AMRs use advanced sensors, onboard AI, and maps to navigate dynamically. AMRs can alter their path in real-time to avoid obstacles or adjust to changes in the environment, making them a highly flexible option for diverse industries.

AGV Navigation and Control Systems

AGVs rely on sophisticated navigation and control systems to ensure precise and safe movement. Some of the common navigation technologies include:

- Laser Target Navigation

- This method uses retro-reflective laser guidance to determine the AGV’s position within its environment. Laser target navigation is accurate and commonly used in many modern AGVs.

- Inertial (Gyroscopic) Navigation

- Inertial navigation systems use transponders embedded in the floor to help AGVs track their movements. A gyroscope detects any deviation from the path and corrects the vehicle’s course, ensuring it stays on track.

- Natural Feature Navigation

- Utilizing cameras and sensors, natural feature navigation allows AGVs to identify and follow unique features within their environment. This technology is particularly useful in complex or changing environments.

How AGVs Work

AGVs operate using a combination of sensors, software, and mechanical components. Their movement is controlled through differential speed, steering wheel control, or a combination of both. AGVs are capable of moving in various directions, including forward, backward, left, right, and even diagonally, enabling them to navigate tight spaces. In addition, AGVs can rotate in place for precise handling of materials.

Benefits of AGV Systems

- Increased Efficiency and Productivity

- AGVs operate continuously and autonomously, allowing for round-the-clock material handling without human intervention. This leads to higher throughput and less downtime.

- Consistent Cost Management

- By reducing labor costs and minimizing the risk of accidents, AGVs provide predictable and consistent operational expenses.

- Improved Flexibility

- AGVs can be adapted for different tasks and industries, offering customizable solutions for businesses with unique material handling needs.

- Space Efficiency

- AGVs require less space compared to traditional automation systems, such as conveyor belts, and can operate in tight spaces like narrow aisles.

- Enhanced Safety

- AGVs reduce the need for human labor in dangerous environments, thus improving workplace safety. Their ability to detect and avoid obstacles helps minimize the risk of accidents.

Applications of Automated Guided Vehicles

- Handling Raw Materials

- AGVs are used to move raw materials to production lines or storage areas. This automation streamlines material handling and improves the overall efficiency of manufacturing processes.

- Work-in-Process Movement

- AGVs transport materials or components between production stages, optimizing the flow of materials through the manufacturing process.

- Finished Product Handling

- After production, AGVs can transport finished products to storage or shipping areas, reducing the risk of product damage from manual handling.

- Inbound and Outbound Handling

- AGVs automate stock replenishment, picking, and shipping, streamlining warehouse operations and reducing human labor.

- Automated Storage and Retrieval

- AGVs can be integrated with Automated Storage and Retrieval Systems (AS/RS) to transport items to and from storage areas efficiently.

Industries That Benefit from AGVs

- Warehousing and Logistics

- AGVs are extensively used in warehouses and distribution centers to automate material transport, improving efficiency and reducing labor costs.

- Manufacturing

- From raw material transport to finished product handling, AGVs are integral to streamlining manufacturing operations.

- Healthcare

- AGVs are increasingly being used in hospitals to transport medications, clean linen, and waste, reducing the need for human involvement in these tasks.

- Retail and E-commerce

- AGVs help with order picking, packing, and sorting, enabling e-commerce businesses to fulfill orders quickly and accurately.

Implementing an AGV System

- Planning and Design

- Designing a custom AGV system is essential to meet specific operational needs. Proper planning ensures that the system integrates seamlessly with existing infrastructure and improves overall productivity.

- Installation and Testing

- Installing an AGV system requires careful setup and testing to ensure proper function and integration with other systems.

Conclusion: The Future of AGVs

AGVs are increasingly becoming a cornerstone of modern industrial automation, offering businesses the flexibility to optimize material handling, improve efficiency, and reduce costs. As technology advances, AGVs will continue to evolve, offering even greater capabilities and further improving operations across industries. Investing in AGV systems can provide substantial long-term benefits, positioning businesses for greater success in an increasingly automated world.

Explore AGV solutions to enhance your warehouse or manufacturing processes today!

Automated Guided Vehicle (AGV) forklifts are transforming material handling operations in warehouses, manufacturing facilities, and logistics centers worldwide. These advanced machines, also known as automated guided forklifts (AGFs) or automated lift trucks, can carry, lift, retrieve, and place loads without human intervention.

Equipped with sophisticated navigation systems, AGV forklifts efficiently handle loads up to 10,000 lbs or more across various surfaces, making them an indispensable asset in modern industrial automation.

Types of AGV Forklifts

AGV forklifts come in multiple designs to meet the diverse needs of industries:

- Counterbalance Forklifts: Modeled after traditional manual forklifts, they are versatile for handling pallets and heavier loads.

- Outrigger Forklifts: Designed for stability during lifting tasks, often used in high-rack storage operations.

- Straddle Forklifts: Ideal for managing oversized loads and tight spaces, providing enhanced flexibility in material handling.

How Do AGV Forklifts Work?

AGV forklifts utilize computer software and sensors to navigate and perform tasks autonomously. Here’s how they function:

- Navigation Systems: Common systems include laser guidance, magnetic tape, natural navigation, and magnetic spots.

- Precision and Efficiency: Sensors and software allow these forklifts to execute tasks with accuracy, eliminating errors.

- Automated Operations: They reduce the need for manual intervention, streamlining repetitive and labor-intensive jobs.

Safety Features and Standards

Safety is a key advantage of AGV forklifts. These machines prioritize workplace safety by integrating:

- Advanced Sensors: Detect obstacles and prevent collisions.

- Cameras: Enhance visibility in complex environments.

- Navigation Systems: Ensure safe and accurate movement.

Benefits of Using AGV Forklifts

AGV forklifts offer numerous advantages, including:

- Increased Productivity: Automating repetitive tasks enables faster operations.

- Cost Savings: Reduces labor costs and minimizes operational errors.

- Scalability: Easily adaptable to growing business needs.

- Integration with Technology: Works seamlessly with warehouse management systems for real-time updates and efficient processes.

Implementing AGV Forklifts in Warehouse Operations

AGV forklifts play a pivotal role in optimizing warehouse operations:

- Material Handling: From pallet stacking to high-rack management, they handle a range of tasks.

- Workflow Automation: They function as conveyor systems, moving goods between workstations.

- System Integration: Integrates with warehouse management systems (WMS) for efficient monitoring and task execution.

Common Applications of AGV Forklifts

AGV forklifts find applications in various industries, including:

- Warehousing: Ideal for high rack management and pallet handling.

- Manufacturing: Transporting materials between assembly lines.

- Logistics: Loading and unloading trucks with precision.

AGV Forklift Maintenance and Support

Regular maintenance ensures the optimal performance and longevity of AGV forklifts. Key aspects include:

- Software Updates: Keeps navigation and automation systems up-to-date.

- Sensor Calibration: Maintains accuracy in operations.

- Customized Support: Tailored maintenance plans cater to industry-specific requirements.

Training and Certification

Proper training is essential for the safe operation and maintenance of AGV forklifts. Manufacturers offer:

- Operator Training: Covers safe usage and handling.

- Certification Programs: Validates the skills and knowledge of operators and maintenance personnel.

Scalability and Flexibility

AGV forklifts are designed to evolve with your business needs:

- Scalable Solutions: Expandable to accommodate growth.

- Custom Configurations: Tailored to specific environments and industries.

- Adaptability: Easily integrated with existing systems and infrastructure.

Security and Data Analytics

To ensure security and optimize performance, AGV forklifts feature:

- Access Control: Prevent unauthorized use with designated operational areas.

- Performance Monitoring: Real-time analytics identify improvement opportunities.

- Custom Data Solutions: Analytics tailored to specific industry needs.

Conclusion

AGV forklifts represent the future of material handling, offering unmatched efficiency, safety, and adaptability. From warehouses to manufacturing facilities, their applications are vast and impactful. By implementing AGV forklifts, businesses can reduce costs, enhance productivity, and streamline operations.

Ready to revolutionize your operations? Explore AGV forklift solutions tailored to your industry today!

Autonomous Mobile Robots (AMRs) represent a cutting-edge solution in robotics, designed to operate independently in dynamic environments. Unlike traditional robots, AMRs possess the remarkable ability to navigate autonomously and make real-time decisions, thanks to advanced sensors, artificial intelligence (AI), and sophisticated software. They are increasingly transforming industries by performing tasks that were once reserved for human labor, offering enhanced flexibility, efficiency, and safety.

Understanding AMRs

At the core of an AMR is its ability to work without direct human intervention. These robots utilize a variety of sensors—such as cameras, LIDAR, and infrared sensors—combined with machine learning algorithms and AI for path planning. This allows them to navigate, adapt to dynamic environments, and perform tasks without requiring physical infrastructure like tracks or predefined paths.

AMRs differ significantly from traditional industrial robots and Automated Guided Vehicles (AGVs). Unlike AGVs, which are typically constrained to fixed routes, AMRs are fully autonomous and can adapt their routes in real-time, making them suitable for a wide range of dynamic applications.

Types of Mobile Robots

AMRs come in various forms, each tailored to specific applications across industries. Here are some common types of AMRs:

- Industrial Robots: These robots are designed to automate manufacturing tasks such as assembly, welding, and material handling.

- Service Robots: These cater to sectors like healthcare, hospitality, and retail, assisting with tasks like patient care, delivery, and customer service.

- Delivery Robots: Autonomous delivery robots are revolutionizing logistics by autonomously transporting goods within warehouses or even across urban environments.

- Autonomous Inventory Robots: These robots are used in warehouses to manage inventory efficiently, scanning and moving products with speed and accuracy.

How Do Autonomous Mobile Robots Work?

AMRs leverage a combination of advanced technologies to operate effectively. The key factors driving their operation include:

- Advanced Sensors and AI: Sensors enable AMRs to detect their surroundings and avoid obstacles. They can make real-time decisions about the best path to take, adapting quickly to environmental changes.

- Machine Learning and Computing: These robots are equipped with AI and machine learning algorithms, which allow them to continuously learn from their surroundings, improving their performance over time.

- Autonomous Navigation: AMRs don’t rely on fixed tracks, making them more flexible in dynamic environments. They can autonomously navigate through open spaces, adjust routes, and even avoid obstacles without human intervention.

Advantages of Autonomous Mobile Robots

The deployment of AMRs offers several advantages to businesses and industries, including:

- Cost Savings: By automating labor-intensive tasks, AMRs help reduce operational costs, such as wages for manual workers.

- Improved Safety: AMRs can take over hazardous tasks, reducing workplace injuries and accidents associated with repetitive or dangerous activities.

- Flexibility: AMRs are highly adaptable. They don’t require the installation of guiding infrastructure, and they can be easily reprogrammed to accommodate changes in tasks or environments.

- Increased Productivity: AMRs can operate 24/7, boosting efficiency and throughput in manufacturing and logistics environments.

- Enhanced Inventory Management: Autonomous robots can help optimize warehouse operations by moving inventory quickly and accurately, reducing human error.

Challenges and Limitations of AMRs

Despite their significant potential, AMRs do come with challenges:

- Technical Limitations: Advanced AI, sensors, and computing power are essential for effective operation. However, these technologies can be costly and technically challenging to integrate.

- Environmental Interference: Dust, dirt, and poor lighting conditions can disrupt the performance of sensors, reducing the robot’s effectiveness.

- Traffic Management: Managing large fleets of AMRs in busy environments requires sophisticated software for coordination and optimization.

- Regulatory Hurdles: There are still regulatory challenges that need to be addressed before AMRs can be widely adopted across industries. Ensuring AMRs adhere to safety standards and operate in compliance with local regulations is crucial.

AMRs vs. AGVs

AMRs and Automated Guided Vehicles (AGVs) are often used interchangeably, but there are key differences:

- AMRs: These robots are autonomous, meaning they can make real-time decisions and navigate dynamically through environments. They are highly flexible and can operate without fixed tracks or infrastructure.

- AGVs: AGVs, in contrast, follow predetermined paths and are ideal for repetitive tasks in controlled settings. While they are useful in certain applications, they lack the adaptability of AMRs.

Industries That Use Autonomous Mobile Robots

AMRs are making a significant impact across various sectors:

- E-commerce: AMRs streamline order fulfillment by automating the movement of goods through warehouses.

- Manufacturing: In manufacturing, AMRs are used to transport materials, parts, and finished products, reducing downtime and improving operational efficiency.

- Healthcare: AMRs are used to deliver medications, clean floors, and even transport food and supplies to patient rooms.

- Logistics and Warehousing: AMRs are particularly beneficial in large distribution centers, where they can quickly and efficiently move goods from one place to another.

Autonomous Mobile Robot Applications

AMRs have a wide range of applications that can benefit businesses in numerous ways:

- Increasing Production: AMRs can work around the clock, handling repetitive tasks without fatigue, which significantly boosts production capacity.

- Improving Worker Safety: By handling dangerous tasks, AMRs reduce the risk of workplace injuries and free up employees to focus on more complex, value-added activities.

- Automation of Repetitive Tasks: AMRs are ideal for automating tasks that require constant repetition, such as material handling, inventory management, and deliveries.

- Enhanced Adaptability: AMRs can adapt to a wide range of environments, from busy warehouses to sensitive healthcare facilities, making them versatile across industries.

Conclusion

Autonomous Mobile Robots (AMRs) are revolutionizing industries by enhancing efficiency, safety, and productivity. Their ability to navigate and perform tasks autonomously makes them highly versatile in dynamic environments, ranging from manufacturing floors to healthcare facilities. With continuous advancements in AI, sensors, and battery technology, the role of AMRs in shaping the future of automation is undeniable.

As AMRs continue to evolve, businesses should consider integrating them into their operations to maximize efficiency and stay ahead in an increasingly competitive marketplace. Exploring AMR solutions for your business could be the key to unlocking new levels of operational excellence.

An Automated Guided Vehicle (AGV) is a type of material handling system that transports goods or materials within a controlled environment, without the need for human operators or drivers. AGVs are equipped with sensors, cameras, and software that allow them to navigate and carry out tasks autonomously. These vehicles are widely employed in manufacturing facilities, warehouses, and distribution centers, and are essential in improving efficiency and reducing the reliance on manual labor..

Brief History of AGVs

The concept of AGVs dates back to 1954, when the Guide-o-Matic was introduced as one of the first driverless vehicles. Over the years, AGVs have undergone significant advancements, incorporating technologies such as cameras, lasers, GPS, and electrically charged tapes for navigation. These improvements have made AGVs highly efficient, adaptable, and safe for a variety of applications in different industries.

Importance of AGVs in Modern Industry

AGVs have revolutionized manual operations in industries such as warehousing and manufacturing, leading to significant improvements in productivity, safety, and cost savings. By automating repetitive tasks like material transport, AGVs minimize human errors, enhance operational efficiency, and reduce workplace injuries. They play a vital role in sectors like manufacturing, warehousing, and logistics, where they streamline material handling and optimize workflows.

Overview of Different Types of AGVs

AGVs come in several types, each designed for specific tasks and environments. In this section, we will provide an overview of the various AGV types, their features, and typical use cases. Understanding these different models can help businesses select the most appropriate AGV for their specific needs.

1. Towing AGVs

Definition: Towing AGVs are designed to tow carts or trailers, moving materials from one location to another.

Applications: They are ideal for transporting goods in bulk across large facilities such as warehouses, manufacturing plants, and distribution centers.

Features: Towing AGVs typically have a low to moderate load capacity and are often used in simple, straight-line movements.

Benefits: These AGVs reduce labor costs and increase material transport efficiency, particularly in large-scale operations where the movement of bulk goods is necessary.

2. Forklift AGVs

Definition: Forklift AGVs mimic traditional forklifts and are designed to lift and move materials using a fork or pallet.

Applications: Common in warehouses, distribution centers, and manufacturing plants, they are ideal for lifting and transporting pallets and heavy materials.

Features: Forklift AGVs are equipped with lifting capabilities and can navigate narrow aisles. They can handle heavy loads and are essential in facilities with high-density storage systems.

Benefits: These AGVs automate lifting tasks, reducing the risk of workplace injuries and improving throughput by eliminating manual lifting operations.

3. Heavy Load AGVs

Definition: Heavy Load AGVs are capable of carrying exceptionally heavy loads, typically used for transporting large or bulky materials.

Applications: They are commonly used in industries like steel manufacturing, automotive, and logistics for handling oversized items.

Features: These AGVs feature high load capacities, strong motors, and durable wheels to handle heavy materials.

Benefits: Heavy Load AGVs enhance efficiency in industries that require the movement of large-scale production materials, reducing manual handling and improving safety.

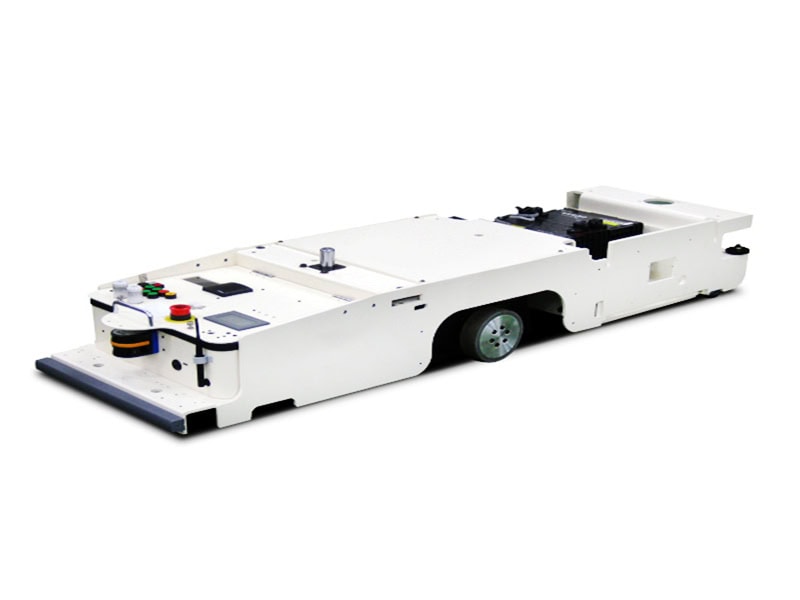

4. Concealed AGVs

Definition: Concealed AGVs are designed to operate discreetly, often hidden under conveyors or integrated within existing systems.

Applications: These AGVs are ideal in environments where material handling needs to be discreet, such as in closed-loop conveyor systems or between production stages.

Features: They are compact, discreet, and designed to operate in confined spaces, often operating in environments where aesthetics or space constraints are a concern.

Benefits: Concealed AGVs are ideal for sensitive environments where the appearance or size of the vehicle could impact the operations or workspace.

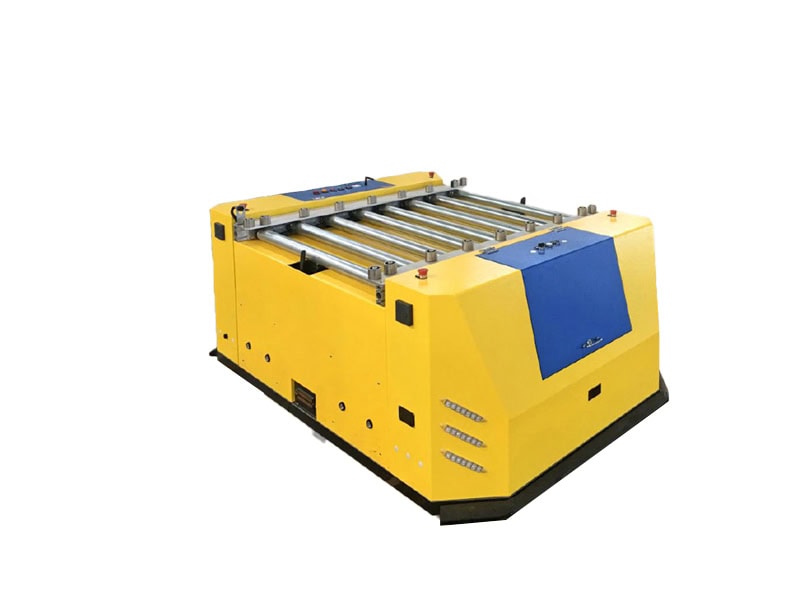

5. Transfer AGVs

Definition: Transfer AGVs are specifically designed to transport materials from one area to another within a facility, especially for continuous flow processes.

Applications: These AGVs are commonly used in warehouses and production facilities to move items between departments or stages in the production process.

Features: Transfer AGVs offer flexible movement and can adapt to various load sizes and transport routes within a facility.

Benefits: Transfer AGVs increase flexibility in material handling and reduce downtime by efficiently moving goods between stages of production or storage areas.

6. Drum Type AGVs

Definition: Drum Type AGVs are specialized vehicles designed for transporting cylindrical objects, such as drums, barrels, or tanks.

Applications: These AGVs are primarily used in industries that deal with chemicals, liquids, or bulk materials, where cylindrical containers need to be moved safely and efficiently.

Features: Drum Type AGVs have specialized features to securely handle cylindrical loads, ensuring that the materials are transported without damage.

Benefits: They provide an efficient and safe solution for transporting cylindrical items that would be difficult to move using traditional equipment like forklifts.

7. Bin Type AGVs

Definition: Bin Type AGVs are designed to carry smaller items or bins, typically used in assembly lines or warehouses.

Applications: These AGVs are ideal for moving small parts, components, or items in large quantities, such as in e-commerce fulfillment centers or component manufacturing.

Features: Bin Type AGVs are small in size and capable of navigating tight spaces, ensuring the safe transport of small items across the facility.

Benefits: By automating the handling of small items, Bin Type AGVs reduce the need for manual labor and help prevent errors in inventory management.

8. Lift Type AGVs

Definition: Lift Type AGVs are equipped with lifting mechanisms to elevate materials and transport them vertically.

Applications: They are used in applications where materials need to be raised to different levels, such as in multi-story warehouses or production areas.

Features: These AGVs have vertical lifting capabilities and can handle a variety of load sizes, making them suitable for operations in multi-level environments.

Benefits: Lift Type AGVs improve space efficiency in facilities with multi-story operations and are perfect for warehouses or manufacturing plants with stacked storage systems.

Conclusion

Automated Guided Vehicles (AGVs) have become an integral part of modern industries, offering a wide range of benefits such as improved efficiency, safety, and cost savings. From towing and forklift AGVs to heavy load and lift type models, businesses can choose from a variety of AGVs to meet their specific material handling needs.

When selecting an AGV for your business, it’s crucial to evaluate factors such as load capacity, operational environment, and specific applications to ensure the optimal solution for your needs. As industries continue to adopt automation, AGVs will play a crucial role in shaping the future of logistics and material handling.

Explore AGV solutions today and start optimizing your operations for enhanced productivity and safety.

What is an Automated Guided Vehicle (AGV)?

An Automated Guided Vehicle (AGV) is a mobile robot that automatically transports goods or materials in facilities like warehouses, factories, and distribution centers. AGVs do not require human operators and follow specific guidance systems that can be either embedded in the floor or powered by wireless technologies. These vehicles are crucial in modern industries for their ability to enhance efficiency, minimize human labor, and improve safety.

Types of AGVs

AGVs come in various forms, each designed to perform specific tasks suited to different industrial environments. Below are some common types of AGVs:

1. Forklift AGVs

Forklift AGVs are automated versions of traditional forklifts, designed to lift and move materials at varying heights. These AGVs are widely used in warehouses and manufacturing facilities to stack pallets, retrieve items from racks, and load or unload trucks. They offer the flexibility to carry large loads without requiring manual intervention.

2. Unit Load AGVs

Unit Load AGVs are designed to transport individual unit loads such as pallets, containers, and racks. They are equipped with platforms or forks to carry these loads, making them ideal for use in warehousing, distribution, and manufacturing settings. Unit Load AGVs streamline operations by automating the transportation of goods across different stages of the supply chain.

3. Towing AGVs (Tuggers)

Towing AGVs, or tuggers, are used to pull carts, trailers, or other wheeled devices autonomously, similar to a train system. They are equipped with a coupling mechanism to connect and transport loads, and are often employed in manufacturing environments where multiple smaller loads need to be moved simultaneously.

4. Heavy Burden Carriers

These AGVs are specially designed to handle heavy-duty loads, making them suitable for industries like construction and automotive. Heavy Burden Carriers can navigate through tight spaces, and some models offer self-loading capabilities, improving both flexibility and efficiency.

5. Hybrid AGVs

Hybrid AGVs combine both automated and manual operation. These vehicles can operate autonomously following predefined paths but can also be controlled manually when necessary. Hybrid AGVs are beneficial in dynamic environments where the flexibility to switch between automated and human-controlled operations is essential.

6. Autonomous Mobile Robots (AMRs)

AMRs, while similar to AGVs, offer a more advanced level of autonomy. They are equipped with sensors, cameras, and advanced AI software, allowing them to understand and interact with their surroundings in real-time. AMRs are more adaptable than AGVs, able to navigate dynamically and avoid obstacles in ways that traditional AGVs cannot.

How Automated Guided Vehicles Work

AGVs rely on various navigation technologies and control systems to operate autonomously within their environments. These technologies ensure that AGVs can move efficiently and safely while completing their tasks.

AGV Navigation Systems

1. Laser Target Navigation

Laser target navigation is one of the most widely used systems in AGVs. It involves a laser scanner that emits beams to detect reflective markers placed along the path. The AGV uses these markers to calculate its position and maintain its course accurately.

2. Inertial (Gyroscopic) Navigation

Inertial navigation systems use gyroscopes to detect changes in direction and make adjustments accordingly. These systems are often paired with transponders embedded in the floor, helping AGVs stay on track and navigate even in areas with limited visual markers.

3. Natural Feature (Natural Targeting) Navigation

This system allows AGVs to use cameras and range-finding sensors to map out and navigate using natural features in their environment, such as walls or landmarks. This method allows AGVs to make more flexible and dynamic route choices, adjusting in real-time to obstacles.

AGV Steering and Control

AGVs are equipped with various steering mechanisms, including differential speed control, steered wheel control, or a combination of both. These systems ensure that the AGV can maneuver precisely and navigate around obstacles while maintaining stability and control.

AGV Traffic Control

To avoid collisions and ensure smooth traffic flow, AGVs employ various traffic control mechanisms such as zone control and collision avoidance systems. These systems help AGVs operate autonomously in environments shared with other robots or human workers, improving safety and efficiency.

Applications and Industries Using AGVs

AGVs have a broad range of applications across various industries. Below are some key industries where AGVs play a crucial role:

1. Manufacturing Facilities

AGVs are frequently used in manufacturing facilities to move raw materials, work-in-process goods, and finished products. They help streamline the production process by transporting materials to different stages of production, reducing manual labor and improving overall efficiency.

2. Warehouses

In warehouses, AGVs are essential for managing inbound and outbound logistics. They transport goods from receiving docks to storage areas, retrieve items from shelves for order picking, and deliver goods to packaging or shipping zones.

3. Automotive Industry

In automotive manufacturing, AGVs are used to transport materials, assist in assembly line processes, and reduce production delays. By enhancing logistics and material handling, AGVs help automotive manufacturers increase efficiency and reduce congestion.

4. Agriculture

AGVs are also gaining traction in the agricultural industry, where they can automate tasks like planting, harvesting, and crop maintenance. These robots improve precision, reduce labor costs, and help farmers optimize their operations.

Benefits of Automated Guided Vehicles

AGVs offer numerous benefits that help businesses increase efficiency, reduce costs, and improve safety:

1. Increased Efficiency and Productivity

By automating repetitive tasks, AGVs can significantly enhance operational efficiency. They reduce the need for human labor in material handling, allowing workers to focus on more complex tasks and improving the overall throughput of operations.

2. Consistent Costs

AGVs help businesses manage costs by providing a predictable cost structure. Unlike labor costs, which fluctuate, AGVs require a fixed investment or rental period, offering more stable and manageable expenses over time.

3. Flexibility

AGVs are highly flexible and can easily adapt to changing environments. They can be reprogrammed to follow new routes or perform different tasks, making them suitable for dynamic production or warehouse environments.

4. Improved Safety

AGVs are equipped with sensors and cameras that enable them to detect obstacles and avoid collisions. By reducing human involvement in hazardous tasks, AGVs improve safety in workplaces, lowering the risk of workplace injuries.

5. Predictive Maintenance

AGVs are capable of self-monitoring their performance through sensors, which help predict potential issues before they occur. This feature allows for proactive maintenance, reducing downtime and preventing costly repairs.

Challenges and Limitations of AGVs

Despite their numerous advantages, implementing AGVs can present challenges:

1. Infrastructure Modifications

To integrate AGVs into existing facilities, businesses may need to make changes to the physical environment, such as installing tracks or markers. These modifications can be costly and time-consuming.

2. Choosing the Right AGV

Selecting the appropriate AGV for a specific application involves evaluating factors such as payload capacity, required speed, navigation methods, and compatibility with existing systems. Choosing the wrong AGV can lead to inefficiencies and additional costs.

3. Technology Limitations

AGVs still rely on predefined paths and can encounter difficulties in unpredictable environments. They may require human intervention in complex situations or when encountering obstacles outside of their programmed routes.

Alternatives to AGVs

While AGVs are an excellent solution for many industrial applications, there are alternatives worth considering:

1. Conveyor Systems

Unlike AGVs, conveyor systems are stationary and require a fixed path. While they are suitable for specific applications, they lack the flexibility and mobility that AGVs offer.

2. Automated Storage and Retrieval Systems (AS/RS)

AS/RS systems provide automated transportation and storage solutions, offering an alternative to AGVs in environments where storage and retrieval tasks are a priority.

3. Autonomous Mobile Robots (AMRs)

AMRs are similar to AGVs but more advanced in their navigation capabilities. AMRs can navigate dynamically, making real-time decisions and adjusting their routes as needed.

Conclusion

Automated Guided Vehicles (AGVs) are transforming industries by providing cost-effective, efficient, and safe solutions for material handling and transportation. From manufacturing to warehousing, AGVs are optimizing processes and increasing productivity. As AGV technology continues to evolve, businesses should consider integrating AGVs into their operations to remain competitive and achieve operational excellence. By evaluating the right AGV solutions and integrating them with existing systems, companies can streamline their logistics and reduce operational costs, setting themselves up for success in a rapidly evolving market.

Definition and Explanation of AGVs

Automated Guided Vehicles (AGVs) are self-operating vehicles designed to transport goods within controlled environments such as warehouses, factories, and distribution centers. These vehicles operate autonomously, taking over tasks traditionally done by forklifts, conveyor systems, or manual labor. AGVs are also known as self-guided vehicles or autonomous guided vehicles, and they are integral to modern automation strategies.

Importance of AGVs in Modern Warehousing

In the fast-paced world of modern warehousing, AGVs play a critical role in ensuring the efficient and automated transportation of goods. These systems help to reduce labor costs, improve productivity, and increase the accuracy of operations. By automating material handling tasks, AGVs enhance the overall effectiveness of supply chains and contribute to a safer and more streamlined work environment.

Types of Automated Guided Vehicles

- Automated Guided Carts (AGCs)

AGCs are the simplest form of AGVs. These vehicles typically follow predefined paths, such as magnetic tracks or guide wires. They are ideal for transporting smaller loads or materials within a facility, offering a cost-effective solution for businesses with less complex automation needs.

- Forklift AGVs

Forklift AGVs are designed to mimic the functions of conventional forklift trucks but operate autonomously. They are equipped with forks to lift and place loads at various heights, making them suitable for handling pallets and other unitized loads. These vehicles can carry heavier loads and perform a variety of tasks without the need for a human operator.

- Unit Load AGVs

Unit Load AGVs are designed to transport individual unit loads like pallets, containers, or racks. These AGVs often come with platforms or forks to support and move the loads efficiently. Unit Load AGVs are widely used in facilities that require the transport of large quantities of goods or raw materials.

- Towing AGVs (Tuggers)

Towing AGVs, or tuggers, are used to pull or tow carts, trailers, or other wheeled devices autonomously. They are equipped with a hitch or coupling mechanism to connect and transport multiple loads at once. Tuggers are particularly useful in large warehouses and manufacturing environments where goods need to be transported across long distances.

- Autonomous Mobile Robots (AMRs)

Autonomous Mobile Robots (AMRs) are an advanced form of AGVs, equipped with sensors and cameras that allow them to understand and interact with their surroundings in real time. AMRs are highly versatile and can navigate complex, dynamic environments without the need for predefined paths.

How AGVs Work

Navigation Systems

AGVs use several navigation systems to operate efficiently within their environment. These systems include laser target navigation, magnetic tape, and natural feature navigation. These technologies enable AGVs to follow predefined paths while avoiding obstacles and ensuring they stay on course.

Steering and Control

AGVs use various steering mechanisms to control their movement. Differential speed control and steered wheel control are common methods, allowing AGVs to change direction or adjust speed. Many AGVs also use zone control sensors to prevent collisions, ensuring smooth and safe operation.

Traffic Control and Management

In environments with multiple AGVs, traffic control systems are used to manage their movements. These systems ensure that AGVs coordinate their operations and avoid collisions with other vehicles, obstacles, or workers. Advanced management systems can adjust the AGVs’ routes in real time to optimize workflow and prevent bottlenecks.

Applications of AGVs in Warehousing

- Transportation of Raw Materials

AGVs are often used to transport raw materials from receiving areas to storage or directly to production lines. This ensures that materials are delivered on time and without human error, reducing delays in production processes.

- Work-in-Process (WIP) Applications

In manufacturing environments, AGVs move parts or materials between workstations, streamlining the flow of goods and reducing the need for manual labor. This improves the overall efficiency of production lines and minimizes downtime.

- Handling Finished Goods

Once production is complete, AGVs are used to transport finished goods to storage or shipping areas. By automating this process, businesses can speed up order fulfillment and reduce the risk of damage to products.

- Inbound and Outbound Handling

AGVs are also critical in inbound and outbound logistics operations. They can assist in stock replenishment, picking processes, and transportation of goods to the appropriate shipping or receiving areas.

Benefits of AGVs in Warehousing

- Increase Efficiency and Productivity

By automating material handling tasks, AGVs eliminate the need for manual labor in repetitive jobs, allowing workers to focus on higher-value tasks. This improves overall warehouse efficiency and increases throughput.

- Consistent Costs and Reduced Labor Expenses

AGVs can be acquired on a per-unit or per-rental basis, allowing businesses to better control costs. Since they reduce the need for manual labor, companies can significantly cut down on labor-related expenses.

- Flexibility and Adaptability in Warehouse Operations

AGVs are highly flexible and can easily adapt to changing warehouse layouts. Some models even offer the ability to re-route in response to obstacles or operational demands, making them an excellent solution for dynamic environments.

Industries Using AGVs

- Manufacturing Facilities

In manufacturing, AGVs are used to transport raw materials, work-in-process goods, and finished products. They streamline material handling processes, improve efficiency, and reduce downtime in production lines.

- Warehouse and Distribution Centers

AGVs play a pivotal role in warehouse and distribution centers by automating the picking, sorting, and shipping of goods. This increases throughput and helps ensure that products are delivered on time.

- E-Commerce and Retail Fulfillment Centers

E-commerce businesses rely on AGVs to enhance order fulfillment and improve shipping efficiency. By automating the handling and transportation of products, AGVs help speed up the order-to-shipment process.

Implementing AGVs in Warehouse Operations

- Assessing Warehouse Operations and Needs

Before implementing AGVs, it is crucial to assess the specific needs and layout of the warehouse. This includes evaluating factors such as inventory management, workflow, and potential obstacles to AGV operation.

- Selecting the Right AGV Type and Navigation System

Choosing the right type of AGV and navigation system is essential for successful implementation. This decision should be based on factors like load capacity, speed, and the complexity of the warehouse environment.

- Training and Support for AGV Operators and Maintenance Personnel

Proper training for AGV operators and maintenance personnel is crucial to ensure that these vehicles are used effectively and safely. Ongoing support and troubleshooting services will also be necessary to keep the systems running smoothly.

Conclusion

Automated Guided Vehicles (AGVs) are an essential part of modern warehouse automation, helping businesses improve efficiency, reduce costs, and enhance safety. With their ability to transport goods autonomously and adapt to changing environments, AGVs are transforming supply chains and warehouse operations.

As industries continue to seek more automated solutions, integrating AGVs into operations is becoming increasingly vital for staying competitive.

Autonomous Mobile Robots (AMRs) are intelligent machines designed to operate independently in dynamic environments. Unlike traditional industrial robots, AMRs stand out due to their ability to autonomously navigate and make real-time decisions, using advanced sensors and sophisticated software. These robots are highly versatile and can adapt to changes in their surroundings, making them ideal for applications in a variety of dynamic settings.

AMRs utilize a combination of sensors, artificial intelligence (AI), machine learning, and computing to plan paths and move efficiently around their environment. Unlike fixed transport industrial robots, AMRs can modify their routes as needed, providing greater flexibility and functionality for industries requiring agile automation solutions.

How Do AMRs Work?

At the core of an AMR is its ability to operate autonomously, meaning it can navigate and complete tasks without the need for human intervention. The integration of advanced sensors and intelligent software is what makes this possible.

AMRs rely on a complex array of sensors to determine their position, navigate obstacles, and adjust their movements. They use these sensors to understand their environment and identify obstacles in real time. The software that controls the AMR continuously analyzes this data to plan paths, modify routes, and ensure the robot reaches its destination efficiently.

AMRs can follow predefined routes or dynamically adapt their path as conditions change. For example, if an obstacle is detected, the AMR can autonomously find a new path to avoid it. In industrial settings, AMRs are often part of a larger fleet of robots, all controlled by a central software system. This software can schedule tasks, distribute duties, manage robot traffic, and even interface with more advanced systems for optimized operations.

Benefits of AMRs in Industrial Automation

AMRs provide several advantages over traditional automation solutions, making them an attractive option for various industries. Key benefits include:

- Flexibility: AMRs can adapt to changes in their environment, allowing them to perform tasks that may require constant adjustments or dynamic re-routing.

- Collaboration with Humans: AMRs can work alongside human workers, enhancing productivity and reducing the workload for employees.

- Increased Efficiency: By performing repetitive tasks autonomously, AMRs free up human workers for more complex and creative tasks.

- Improved Accuracy and Consistency: AMRs offer greater precision and reliability in performing routine tasks, such as material handling or order fulfillment.

- Cost-Effectiveness: While the initial investment in AMRs can be high, their long-term cost-effectiveness is clear, thanks to their ability to operate 24/7 without breaks or fatigue.

Applications of AMRs

AMRs have found widespread use across various sectors due to their ability to adapt, work autonomously, and improve operational efficiency. Here are some of the most common applications:

- Warehousing and Logistics: AMRs are commonly used for order fulfillment, material handling, and inventory management in warehouses. They can autonomously transport goods and materials, increasing efficiency and reducing human labor costs.

- Healthcare: In hospitals and healthcare facilities, AMRs are used to transport medications, medical supplies, and patient records. They can access restricted or hazardous areas, enhancing safety and streamlining operations.

- Manufacturing: AMRs can deliver materials to production lines, assist with assembly tasks, or perform routine maintenance, thereby improving productivity and reducing downtime.

- Dangerous or Restricted Areas: AMRs are particularly useful in environments where human presence is risky, such as in nuclear plants, fire-fighting operations, or military settings. They can navigate hazardous environments autonomously, ensuring safety without human risk.

Comparison with Other Industrial Robots

While AMRs and Automated Guided Vehicles (AGVs) are often confused, there are significant differences between them.

- AMRs vs. AGVs: The key distinction between AMRs and AGVs is that AMRs are capable of autonomous navigation in dynamic environments, while AGVs typically follow predefined paths and are better suited for static, repetitive tasks. AMRs offer more flexibility, can navigate freely around obstacles, and adapt to changing conditions, whereas AGVs are more limited in their versatility and are typically used in controlled, predictable environments.

- Advantages of AMRs over AGVs: AMRs are more sophisticated, flexible, and cost-effective than AGVs, offering better adaptability and reduced infrastructure dependency. While AGVs work well for specific tasks in fixed environments, AMRs excel in environments where adaptability, mobility, and real-time decision-making are crucial.

Integrating AMRs with Other Systems

AMRs can be integrated with other systems to improve operational efficiency. A prime example of this is the integration of AMRs with the AutoStore automated storage and retrieval system (AS/RS). AMRs can transport target totes, racks, and bins from the AutoStore system, making it more flexible and adaptable compared to traditional AGVs. This integration allows warehouses to streamline their operations and improve space utilization, while increasing throughput.

AMRs can also be combined with other technologies, such as robotic arms or conveyors, to perform more complex tasks and further enhance automation.

Challenges and Limitations of AMRs

While AMRs offer many benefits, they also come with their own set of challenges:

- Technical Challenges: Integrating AMRs with existing systems and infrastructure can be complex. Ensuring that AMRs work seamlessly with other automation systems requires careful planning and coordination.

- Operational Challenges: Developing and maintaining the software and algorithms that control AMRs is an ongoing challenge. The AI and machine learning algorithms used to navigate and plan paths must be continuously updated and optimized.

- Financial Challenges: The initial investment in AMRs and the infrastructure required for their deployment can be substantial. However, this is often offset by the long-term savings in labor and operational costs.

- Accuracy: While AMRs are highly efficient, they may face challenges in terms of precise location and positioning compared to AGVs, especially in complex environments.

Conclusion: The Future of AMRs

AMRs represent a significant leap forward in industrial automation. Their ability to navigate autonomously, adapt to changing environments, and work seamlessly alongside human workers makes them an invaluable tool across a range of industries. By understanding the technology behind AMRs and addressing the challenges involved, businesses can fully leverage these robots to improve efficiency, reduce costs, and drive innovation.

As AMRs continue to evolve, their role in industrial automation will only grow, bringing new opportunities for businesses to enhance their operations and stay ahead in an increasingly competitive market.

In today’s fast-paced industrial landscape, Automated Guided Vehicles (AGVs) are revolutionizing the way businesses handle logistics and manufacturing processes. Originating in the mid-20th century, AGV robots have evolved into sophisticated, autonomous systems that significantly accelerate the movement of goods within warehouses and production centers. These intelligent machines are integral to modern material handling, offering unparalleled efficiency and reliability. But how exactly do AGV robots work, and what makes them indispensable for contemporary businesses? This article delves into the mechanics, types, applications, and benefits of AGV robots, providing a comprehensive understanding for those interested in integrating this technology into their operations.

If you’re considering adopting AGV robots to streamline your logistics or manufacturing processes, this guide will equip you with the knowledge needed to make informed decisions. Contact us today to explore tailored AGV solutions that meet your specific business needs.

What Are AGV Robots?

Automated Guided Vehicles (AGVs), also known as automated or automatic guided vehicles, are robotic systems employed in logistics and manufacturing environments to transport materials, products, or equipment between different areas of a facility. Unlike traditional material handling equipment, AGV robots operate autonomously without the need for human intervention. They navigate predefined routes using advanced technologies such as laser navigation and machine vision, efficiently moving loads of varying sizes and weights across warehouses and production centers.

AGV robots are a cornerstone of modern logistics systems, enhancing operational efficiency by automating repetitive and labor-intensive tasks. However, implementing AGV systems requires significant initial investments and careful planning to ensure seamless integration with existing workflows. Despite their limitations in fixed routing and lack of human-like decision-making, AGVs remain a vital solution for environments with high volumes of goods and stable transportation routes.

Recent advancements have introduced AGV robots with artificial intelligence (AI), known as Autonomous Intelligent Vehicles (AIVs), which offer greater flexibility and adaptability in dynamic warehouse settings. These intelligent systems are particularly beneficial for facilities requiring high throughput and the ability to handle varying transportation demands without relying on fixed paths.

Definition of AGV

An Automated Guided Vehicle (AGV) is a type of robotic vehicle designed to transport materials, products, or equipment within controlled environments such as manufacturing facilities, warehouses, or distribution centers. Equipped with sophisticated navigation systems, sensors, and control mechanisms, AGVs move autonomously and perform tasks with precision and accuracy. They play a crucial role in modern material handling processes, enhancing efficiency and reducing the need for manual labor in logistics operations.

Types of AGVs

AGVs come in various types, each tailored to specific tasks and operational environments. Understanding the different types can help businesses select the most suitable AGV for their needs:

- Forklift AGVs: These AGVs emulate the functions of traditional forklift trucks but operate without a human driver. Ideal for lifting and transporting pallets and other heavy loads within a facility, Forklift AGVs enhance safety and efficiency in material handling.

- Unit Load AGVs: Designed to transport individual unit loads such as pallets, containers, or racks, Unit Load AGVs are perfect for moving goods between different areas of a warehouse or production line, ensuring smooth and continuous operations.

- Towing AGVs: Built to pull or tow carts, trailers, or other wheeled devices autonomously, Towing AGVs are suitable for applications requiring the movement of multiple loads simultaneously, optimizing material flow within the facility.

- Heavy Burden Carriers: These robust AGVs are engineered to handle heavy loads and operate in extreme environments, such as steel mills or foundries, where durability and reliability are paramount.

- Autonomous Mobile Robots (AMRs): Unlike traditional AGVs, AMRs use advanced sensors and algorithms to navigate and interact with their surroundings in real-time, allowing them to operate in dynamic environments without the need for fixed routes.

AGV Categories

AGVs can be categorized based on their navigation systems, steering and control mechanisms, and application areas. Common categories include:

- Laser Guided Vehicles (LGVs): Utilizing laser beams for navigation, LGVs offer high precision and flexibility in route planning, making them suitable for complex and dynamic environments.

- Magnetic Guidance Systems: These AGVs follow magnetic strips or tapes placed on the floor to navigate through the facility. This method is cost-effective and easy to implement, widely used in manufacturing and warehouse settings.

- Infrared (IR) Guided Vehicles: Employing infrared beams for navigation, IR-guided AGVs are often used in environments where other navigation methods may be less effective.

- Radio Frequency Identification (RFID) Guided Vehicles: These AGVs use RFID tags and readers to guide their movement, allowing for accurate tracking and navigation within the facility.

- Vision Guided Vehicles: Equipped with cameras and computer vision algorithms, Vision Guided AGVs navigate by recognizing and interpreting visual cues from their environment, enhancing their adaptability and precision.

Applications of AGV Robots in Material Handling

AGV robots play a pivotal role in performing logistics operations, such as distributing stock between different storage areas, loading and unloading goods in receiving and dispatch zones, and other essential tasks. In distribution centers, AGV robots efficiently transport goods between various sections, optimizing operations and enhancing overall operational efficiency. Their ability to handle heavy loads makes them indispensable in production centers for moving parts of different sizes to assembly lines. Common applications of AGV robots include:

- Truck Loading and Unloading: AGV robots can autonomously load and unload goods onto trucks, performing the functions of forklifts or other conventional handling equipment with increased precision and efficiency.

- Product Storage and Retrieval: AGV robots place items in their designated storage locations and move goods to order fulfillment areas. This automated movement facilitates agile, safe, and efficient replenishment of racks and pick stations, enhancing both product and operator productivity.

- Connection with Production Centers: AGV robots transport large, heavy, and bulky goods from warehouses to production lines, especially in industries like automotive and aerospace. By linking production lines with automated storage and retrieval systems (AS/RS), AGVs ensure timely and efficient material flow.

- Distribution for Kitting: AGV robots streamline the replenishment of goods to various kit assembly stations by following predetermined routes. This ensures that stock is delivered in the exact quantities required, enhancing the efficiency of kitting processes.

AGV robots are utilized across diverse sectors, including manufacturing (especially in just-in-time environments), food and beverage, pharmaceuticals, and automotive industries, where they supply production lines with goods precisely when needed.

How AGV Robots Work with Sophisticated Control Systems

AGV robots operate through a combination of advanced control systems and integrated components that ensure precise task execution and seamless interaction with other systems. The core elements of an AGV robot include:

- Navigation System: Responsible for receiving and processing information to follow preset routes or directions, the navigation system utilizes technologies such as laser, wire, and magnetic guidance to drive the vehicle accurately.

- Safety System: AGV robots are equipped with safety features tailored to their functions, ensuring safe operation. For instance, laser scanners can detect obstacles and halt the vehicle’s movement to prevent collisions.

- Power System: AGV robots are powered by batteries that provide the necessary energy for movement. The type of battery and charging method varies based on the specific requirements of the warehouse or production center.

- Motion System: Comprising motors, wheels, and other components, the motion system enables AGV robots to move and perform tasks efficiently. This includes mechanisms for lifting and transporting loads as needed.

- Vehicle Controller: Guided by a programmable logic controller (PLC), the vehicle controller interprets information from the software and manages the autonomous movement of the AGV robot.

The movement and workflows of AGV robots are coordinated by higher-level programs such as Warehouse Management Systems (WMS). These software solutions oversee all activities within the logistics facility, ensuring that AGV tasks are synchronized with other automated systems to optimize overall efficiency.

Navigation Systems in AGVs

AGVs utilize various navigation systems to move efficiently and perform tasks with precision. Common navigation systems include:

- Magnetic Tape: A magnetic tape is laid on the floor, and the AGV follows this tape to navigate through the facility. This method is cost-effective and straightforward to implement, making it popular in many manufacturing and warehouse environments.

- Laser Guidance: A laser beam emitted from the AGV guides the vehicle’s movement. This system offers high precision and flexibility, suitable for complex and dynamic environments where adaptability is crucial.

- Inertial Navigation: Using gyroscopes and accelerometers, the AGV determines its position and orientation, allowing it to navigate without relying on external references. This system is ideal for environments where other navigation methods may be impractical.

- Natural Feature Navigation: AGVs equipped with sensors and algorithms detect and navigate around natural features such as walls and obstacles. This method provides greater flexibility and adaptability in dynamic environments.

Steering and Control Mechanisms in AGVs

AGVs employ various steering and control mechanisms to ensure precise movement and task execution. Common mechanisms include:

- Differential Speed Control: By controlling the speed of each wheel independently, AGVs can steer and maneuver accurately, allowing for smooth navigation around obstacles and tight corners.

- Steered Wheel Control: Similar to how a car operates, AGVs with steered wheels use this mechanism to control their direction, providing smooth and precise movement across the facility.

- Combination Control: Some AGVs utilize a combination of differential speed control and steered wheel control to achieve optimal maneuverability and control, especially in complex environments where enhanced agility is required.

Understanding these steering and control mechanisms allows businesses to appreciate the versatility and precision that AGV robots bring to their logistics and manufacturing processes.

AGV Robots: Success Stories

Real-world applications of AGV robots demonstrate their effectiveness in enhancing operational efficiency and reducing manual labor. Here are some notable success stories:

- Normagrup, Spain: A leading company in the emergency lighting sector, Normagrup employs four Autonomous Intelligent Vehicles (AIVs) to link its production lines with its Automated Storage and Retrieval System (AS/RS) for boxes. The Easy WMS from Mecalux manages the AGV robots, notifying them when items leave the AS/RS. The AGVs then transport these items to the required production lines seamlessly integrating the miniload system with other automated processes.

- Novartis, Poland: In the biotech sector, Novartis utilizes AGV robots to connect its automated rack-supported warehouse with production lines. The Mecalux Group’s software organizes goods within the warehouse, ensuring timely delivery to production lines. According to Tomasz Marchewa, Supply Chain Manager at Novartis, automating in-warehouse transport was a strategic priority to enhance operational efficiency.

- Clairefontaine, France: At the Clairefontaine facility in Alsace, AGV forklifts handle internal goods transport by moving products between storage zones and various operational areas, including receiving, picking, and dispatching zones. The facility leverages the Easy WMS to control and coordinate all logistics operations, demonstrating the critical role of AGV robots in maintaining efficient workflows.

AGV Robots for Autonomous Goods Movement in Distribution Centers

AGV robots serve as an automated solution for accelerating the flow of stock within warehouses and connecting logistics facilities with production centers. While traditional AGV robots follow predetermined routes, the integration of AI-powered AGVs, known as Autonomous Intelligent Vehicles (AIVs), offers enhanced flexibility by eliminating the need for fixed paths.

To address the limitations of traditional AGVs, companies can complement them with higher-throughput automated solutions such as stacker cranes and conveyors, or integrate Autonomous Mobile Robots (AMRs) that navigate dynamically without fixed routes. This hybrid approach ensures that businesses can handle high volumes of goods efficiently while maintaining adaptability to changing operational demands.

Conclusion

Automated Guided Vehicles (AGVs) are transforming the landscape of logistics and manufacturing by enhancing efficiency, reducing costs, and improving safety. As businesses strive to optimize their operations, AGV robots offer a versatile and scalable solution that meets the demands of modern material handling. With applications spanning across various industries—from manufacturing and healthcare to e-commerce and automotive—AGV robots are indispensable in driving automation forward.

If you’re interested in exploring how AGV robots can benefit your business, contact us today. Our expert consultants will guide you in selecting and implementing the right AGV solutions tailored to your specific needs, ensuring a seamless and efficient integration into your operations.

Contact Us

Ready to elevate your logistics and manufacturing processes with AGV robots? Reach out to our team of experts today to discuss customized AGV solutions that align with your business objectives. Enhance your operational efficiency and stay ahead in the competitive market with our cutting-edge AGV technology.

IntroductionIn the rapidly evolving world of automation, Autonomous Mobile Robots (AMRs) are making a significant impact on various industries. These intelligent machines are designed to operate autonomously in dynamic environments, offering numerous advantages over traditional robots and Automated Guided Vehicles (AGVs). AMRs are revolutionizing the way businesses approach logistics, manufacturing, healthcare, e-commerce, and more. But what exactly are AMRs, and how do they work? This article will explore the essential aspects of AMRs, their applications, advantages, and limitations, while also providing insight into the future of these autonomous robots.

If you’re considering integrating AMRs into your operations, this comprehensive guide will help you understand how these technologies can improve efficiency, safety, and productivity. Contact us to learn more about AMR solutions tailored to your business needs.

What Are Autonomous Mobile Robots (AMRs)?

Autonomous Mobile Robots (AMRs) are intelligent, self-driving machines designed to perform tasks independently without human intervention. What distinguishes AMRs from traditional robots is their ability to navigate and make decisions autonomously, using advanced sensors, artificial intelligence (AI), machine learning, and other sophisticated technologies.

Unlike fixed transport systems like Automated Guided Vehicles (AGVs), AMRs can adapt to dynamic environments, rerouting and changing tasks as needed. This flexibility allows AMRs to function in ever-changing spaces, such as warehouses, factories, hospitals, and retail environments.

AMRs are equipped with cameras, lidar (light detection and ranging), ultrasonic sensors, and other devices to detect obstacles in real-time, allowing them to avoid collisions and navigate complex environments safely.

Types of Mobile Robots

AMRs are classified into various categories based on their applications and functionalities. These types include:

- Industrial Robots: These robots are designed to automate repetitive tasks in manufacturing, such as assembly, packaging, material handling, and quality control. They significantly reduce labor costs and increase production efficiency.

- Service Robots: Service AMRs are used in sectors such as healthcare, hospitality, and retail. They assist in customer service, cleaning, and delivery tasks, improving efficiency and customer satisfaction.

- Delivery Robots: These robots are designed for transporting goods autonomously. They are increasingly used in e-commerce warehouses to move products from shelves to packing stations. Some delivery robots are also deployed in urban environments to transport goods to customers.

- Autonomous Inventory Robots: These robots are used for inventory management in warehouses. They can transport materials, scan barcodes, and update stock levels in real-time, making inventory tracking more efficient and accurate.

How Do AMRs Work?

AMRs are powered by sophisticated systems that allow them to operate autonomously in a variety of settings. The core technology behind AMRs includes:

- Sensors: AMRs are equipped with a variety of sensors, including lidar, cameras, infrared sensors, and ultrasonic sensors. These sensors help the robots perceive their environment and avoid obstacles.

- Artificial Intelligence (AI) and Machine Learning: AMRs utilize AI algorithms to analyze sensor data and make real-time decisions. Machine learning algorithms allow AMRs to improve their navigation and task performance as they gain experience in different environments.

- Path Planning and Navigation: The robots use advanced path planning techniques to determine the most efficient route from point A to point B while avoiding obstacles. Unlike AGVs, AMRs do not require predefined paths, making them more adaptable in dynamic settings.

- Autonomous Charging: Many AMRs are equipped with autonomous charging capabilities, allowing them to recharge themselves when their battery levels are low, ensuring continuous operation.

Advantages of Autonomous Mobile Robots (AMRs)

AMRs offer numerous benefits for businesses looking to enhance their operations. These advantages include:

- Cost Savings: AMRs can automate tasks that would otherwise require human labor, leading to significant cost savings. By reducing the need for manual labor, businesses can reallocate resources to more strategic tasks.

- Improved Safety: AMRs are designed to handle dangerous, repetitive, and physically demanding tasks, reducing the risk of workplace injuries. By automating tasks such as material handling or transportation of hazardous materials, AMRs help improve workplace safety.

- Increased Flexibility: Unlike AGVs, which follow predefined paths, AMRs can navigate freely and adapt to changing environments. This makes them ideal for environments where the layout or operational needs may change frequently, such as warehouses or factories.

- Higher Productivity: AMRs can work 24/7 without fatigue, significantly increasing productivity. They can perform a wide range of tasks, from moving goods to performing inventory checks, all while optimizing workflow efficiency.

- Enhanced Accuracy: With their advanced sensors and AI-driven systems, AMRs can perform tasks with a high degree of accuracy. Whether it’s inventory management or quality control, AMRs help reduce errors and improve operational precision.

Challenges and Limitations of AMRs

While AMRs offer significant advantages, they are not without challenges. Some of the key limitations include:

- Technical Constraints: Although AMRs are highly advanced, they still face limitations in terms of sensor technology and software capabilities. In environments with heavy interference (e.g., dust, poor lighting), the effectiveness of AMRs may be compromised.

- Traffic Management: As the number of AMRs in a facility increases, managing their movements becomes more complex. Software systems must be sophisticated enough to avoid collisions and optimize robot traffic flow.

- Regulatory Hurdles: AMRs must comply with safety regulations, such as ISO 3691-4:2023 and R15.08-1-2020 in the US. Additionally, navigating regulatory frameworks in various regions can be challenging as governments develop standards for autonomous technologies.

- Cost of Implementation: The initial investment for AMR systems can be high, especially for businesses that need a fleet of robots. However, over time, the cost savings from automation typically outweigh the initial investment.

AMRs vs. AGVs: Understanding the Differences

While AMRs and Automated Guided Vehicles (AGVs) may seem similar, they differ significantly in their capabilities.

- Navigation: AMRs are autonomous and use AI, sensors, and machine learning to navigate freely and avoid obstacles. AGVs, on the other hand, rely on predefined tracks or magnetic strips to follow specific routes.

- Flexibility: AMRs can adapt to dynamic environments and change their routes on the fly, while AGVs are limited to following fixed paths and are less adaptable in changing conditions.

- Applications: AMRs are ideal for environments where flexibility and adaptability are crucial, such as warehouses, hospitals, and urban logistics. AGVs, due to their predictable nature, are best suited for repetitive tasks in controlled environments.

Industries That Use Autonomous Mobile Robots

AMRs have broad applications across various industries. Some of the sectors utilizing AMRs include:

- E-commerce: AMRs help streamline operations in e-commerce warehouses by automating inventory management, order fulfillment, and transportation of goods.

- Healthcare: In hospitals, AMRs can deliver medication, transport medical supplies, and even sanitize high-touch surfaces, reducing the workload of hospital staff.

- Manufacturing: AMRs automate material handling, transport goods between production lines, and monitor factory operations in real time, improving manufacturing efficiency.

- Logistics: AMRs are used in logistics hubs for transporting goods, sorting packages, and managing inventory.

- Retail: In retail environments, AMRs can assist with stock management and provide customer service, enhancing the shopping experience.

Future of Autonomous Mobile Robots (AMRs)

The future of AMRs is promising, with continuous advancements in AI, sensor technology, and battery performance. The integration of AMRs with other technologies, such as AutoStore and automated storage systems, is already revolutionizing warehouses and supply chains.

As AI and machine learning evolve, AMRs will become even more efficient, adaptable, and capable of performing complex tasks across various industries. Additionally, advancements in battery technology will enable AMRs to operate for longer periods without recharging, further improving their utility in 24/7 environments.

Conclusion

Autonomous Mobile Robots (AMRs) are transforming industries by improving efficiency, reducing costs, and enhancing safety. As businesses look for innovative ways to streamline operations, AMRs offer a versatile and scalable solution. With applications across manufacturing, healthcare, e-commerce, and logistics, AMRs are a key enabler of automation.

If you’re interested in exploring how AMRs can benefit your business, contact us today. Our experts can help you identify the right AMR solutions tailored to your needs, ensuring a smooth and efficient integration into your operations.

This guide explores AGVs in detail, providing insights into their types, applications, and benefits to help you make informed decisions for your business.

What is an Automated Guided Vehicle (AGV)?

1、Definition and Key Features

An Automated Guided Vehicle (AGV) is a self-driving system designed to transport materials within a facility with minimal or no human intervention. Operating on predefined routes or leveraging sophisticated navigation systems, AGVs handle tasks like moving raw materials, work-in-process, and finished goods with precision and efficiency.

2、How AGVs Enhance Material Handling