Extruder machine plastic technology transforms raw plastic into finished products like tubing, profiles, and films. This article covers how these machines work, the different types available, and key components, helping you make informed manufacturing decisions.

Key Takeaways

- Plastic extrusion is a key manufacturing process that transforms thermoplastic materials into continuous products through heating and pressure.

- There are different types of plastic extruders, including single-screw and twin-screw, each suited for specific applications and offering unique advantages.

- Quality assurance in plastic extrusion is essential for maintaining product consistency, involving monitoring melt flow and regular maintenance of extrusion machines.

Understanding Plastic Extrusion Machines

At its core, plastic extrusion is a popular manufacturing method used to produce large quantities of continuous products with uniform cross-sections. This process involves melting thermoplastic materials and pushing the molten plastic through a die under pressure. The result is a versatile manufacturing technique capable of creating a wide range of products, from plastic tubing to complex profiles.

Plastic extrusion machines, or extruders, are the workhorses of this process. These machines are designed to handle various thermoplastic materials, transforming them from raw pellets into finished products through a series of precisely controlled steps. Understanding the key components and types of plastic extruder machines helps optimize your manufacturing process and achieve high-quality results with plastic extrusion equipment.

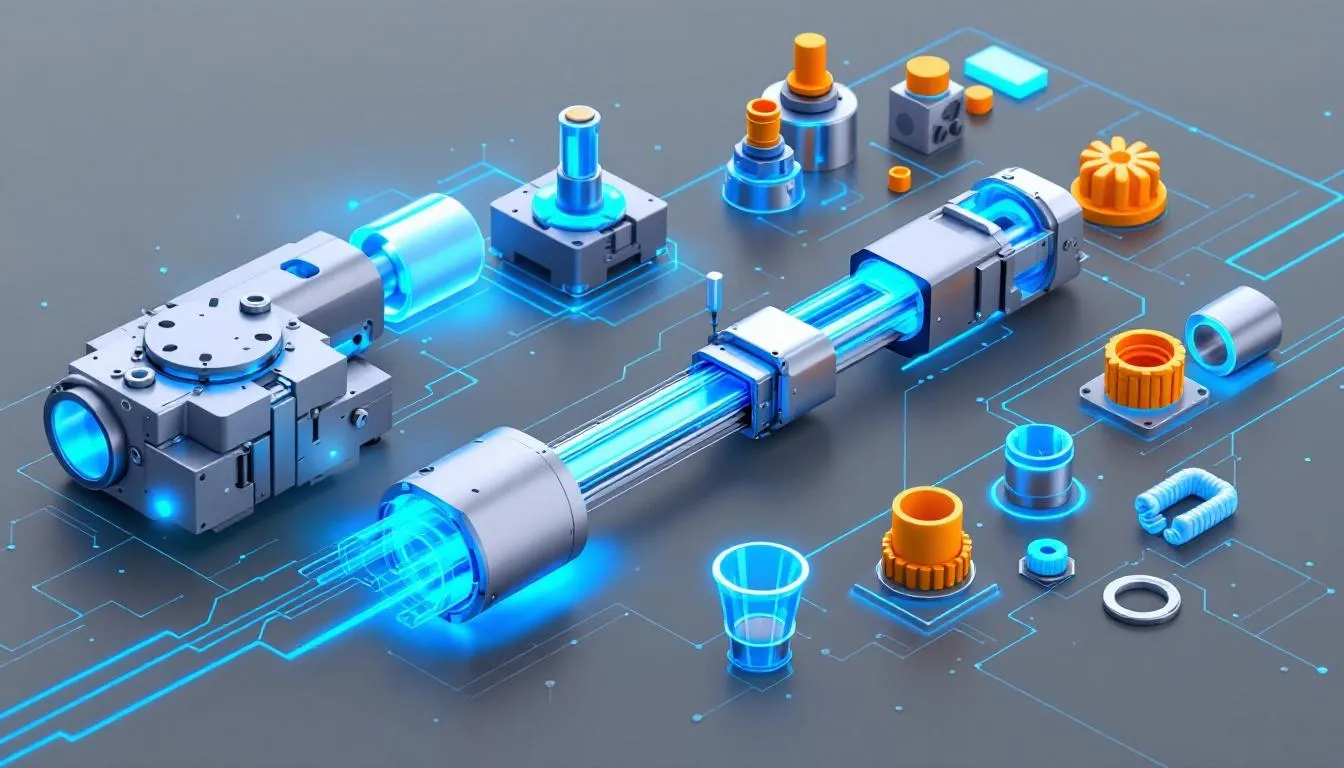

Key Components of an Extruder Machine

The hopper is where the journey of plastic granules begins. This component serves as the storage and feeding mechanism, delivering the raw plastic into the machine for processing. Once inside the extruder, the plastic granules are heated and melted down to form a consistent molten state, ready to be shaped into the final product.

The breaker plate is another essential component, acting as a filter to maintain pressure within the barrel while ensuring that the material is free from contaminants. The die, often considered the heart of the extrusion machine, determines the specific shape of the extruded product as the molten plastic passes through it and barrels of material are processed.

Finally, cooling systems are crucial for rapidly cooling and solidifying the extruded profiles, ensuring they maintain their desired shape and structural integrity.

Types of Plastic Extruders

Plastic extruders come in various forms, each tailored to specific manufacturing needs. There are three primary categories of plastic extruders. These include single-screw, twin-screw, and ram extruders. Each type offers unique advantages and is suited for different applications, so choosing the right extruder for your specific production requirements is vital.

Single-screw extruders are straightforward and reliable, making them a popular and affordable choice for many applications. They are also easier to operate compared to their twin-screw counterparts.

Twin-screw extruders are known for their enhanced mixing capabilities, making them ideal for more complex formulations. Knowing the differences between these types helps in selecting the best equipment for your needs.

Single Screw Extrusion Machines

Single screw extrusion machines operate with a single screw that combines materials and pushes them through a die. This technology is the backbone of many plastic extrusion lines, known for its reliability and efficiency. Single screw extruders can process up to 100% recycled plastic, including PET-flakes and rHDPE, which is a significant advantage for environmentally conscious manufacturers.

The design of the screws in single screw extruders ensures a high quality of the melt during the extrusion process, guaranteeing fast and gentle melting of the material. This makes single screw extrusion machines suitable for producing a wide range of plastic products, from simple profiles to complex shapes, including one screw designs.

Twin Screw Extrusion Machines

Twin screw extrusion machines are renowned for their superior mixing capabilities, which allow for the blending of different materials and additives. This enhanced mixing quality makes them particularly suitable for handling complex formulations and producing products with unique properties.

The twin screw design ensures thorough mixing and even distribution of materials throughout the extrusion process. This capability is invaluable for applications needing precise control over material properties, such as producing high-performance plastics and specialized compounds.

Twin screw extruders are a versatile and powerful option for manufacturers looking to achieve consistent, high-quality results.

The Extrusion Process

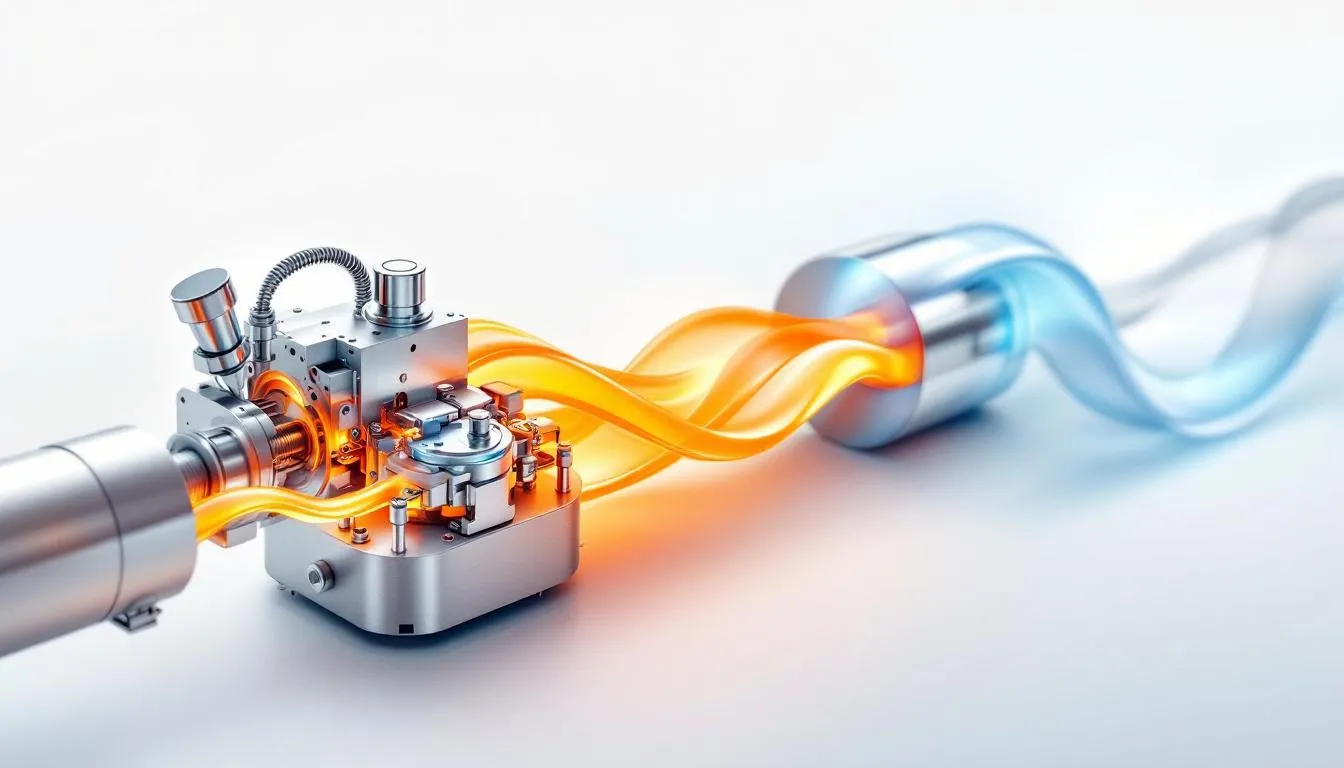

The extrusion process involves transforming raw plastic pellets into solid shapes using heat and pressure. Plastic extrusion machines are used to produce continuous lengths of products like tubing and sheets. The process begins with feeding raw thermoplastic materials into the machine, where they are heated to form a molten state.

Once molten, the plastic is forced through a die that shapes the material into the desired profile, often resembling a cylinder. The die serves as a mold, ensuring an even flow of molten plastic and producing a consistent final product, essential for manufacturing various plastic products with precise dimensions and high-quality finishes.

Thermoplastic Materials Used in Extrusion

Common thermoplastic materials commonly used in extrusion include:

- Polyethylene

- Polypropylene

- PVC

- ABS

- Acrylic

These materials typically come in small, solid resin plastic material beads before being processed. Thermoplastics are favored in the extrusion process due to their ability to be melted and reformed multiple times without significant degradation.

The process starts by melting thermoplastic materials, which can be in the form of powders or pellets, and forcing them through a die. This versatility allows manufacturers to produce a wide range of products, from simple plastic tubing to complex, custom-designed profiles.

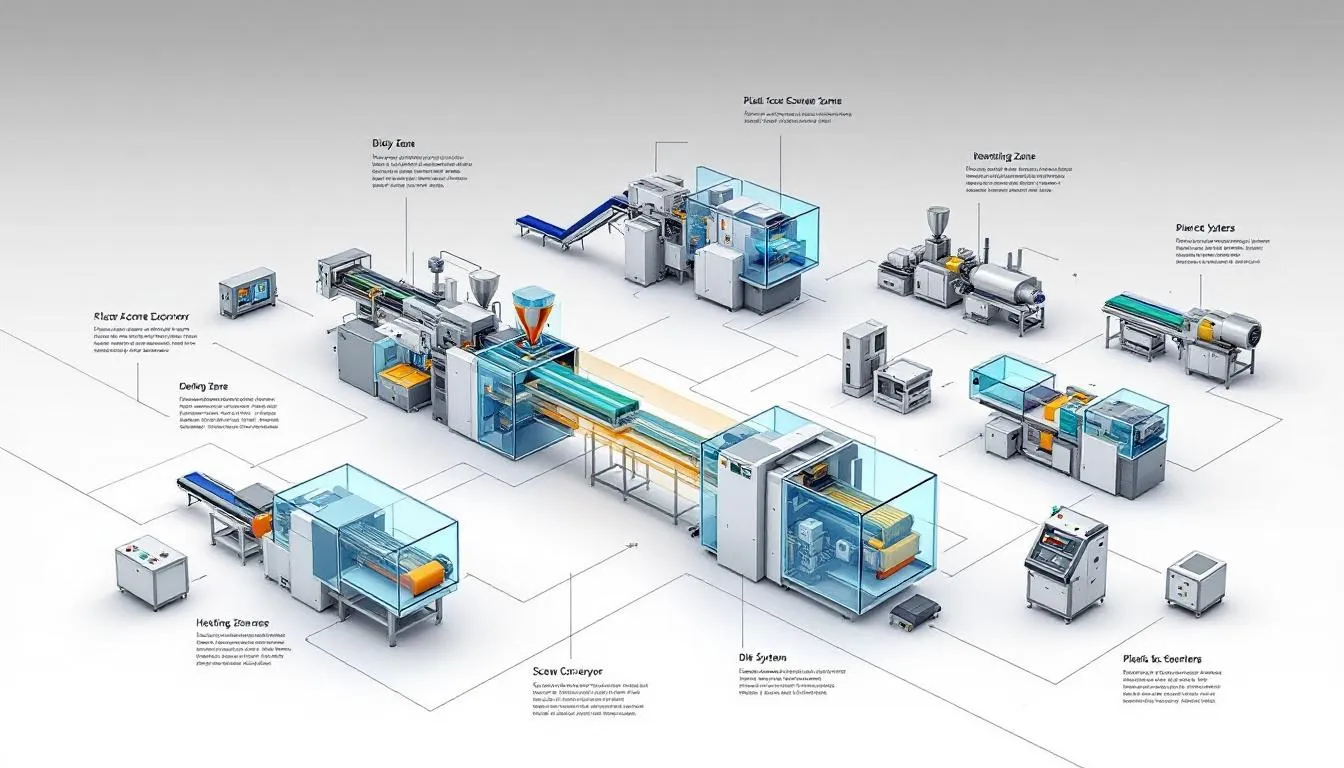

Downstream Equipment in Extrusion

Downstream equipment is crucial in the extrusion process for shaping, cooling, and finishing extruded products. Common downstream equipment includes cutters, pullers, and winders. Cutters ensure precise sizing of extruded products to meet specific length requirements.

Pullers maintain a consistent speed during the extrusion process, ensuring the product does not distort. Winders collect and wind the finished extruded product into manageable rolls, facilitating storage and transport. This equipment ensures the final products meet desired specifications and quality standards.

Customization and Flexibility in Extrusion

Customization in plastic extrusion allows manufacturers to tailor designs specifically to meet unique product requirements. These customization options enhance extruder capabilities, enabling production of a wide range of designs and specifications. This flexibility maximizes efficiency and performance in diverse manufacturing applications.

The impact of customization in plastic extrusion is significant, contributing to meeting diverse manufacturing needs and creating unique products tailored to specific requirements. This section will explore co-extrusion techniques and flexible design features that enhance the production process.

Co-Extrusion Techniques

Co-extrusion enables the combination of different plastics to achieve specific functionalities in a single product. This technique produces multilayered products, where each layer enhances unique properties like strength and flexibility.

In co-extrusion, multiple extruders supply distinct materials simultaneously, resulting in products with superior characteristics compared to those made from a single material. This process benefits the creation of complex profiles and products with enhanced performance.

Flexible Design Features

Flexible design features in extrusion systems enhance the production process by accommodating diverse film types and product specifications. Integrating multiple extruders in a single line allows manufacturers to produce a range of films and products tailored to specific market needs.

These flexible design features optimize production for different product types in business, enhancing efficiency and output. The ability to produce customized products with unique properties is a significant advantage in competitive markets.

Quality Assurance in Plastic Extrusion

Quality assurance in plastic extrusion is critical for maintaining product consistency and performance. Quality control measures are essential for preventing defects and ensuring that products meet specified standards. This involves both raw material and final product testing to ensure product integrity.

Final product inspections assess factors like color consistency, dimensional stability, and structural integrity to ensure complete quality. High-quality standards in plastic extrusion are vital for producing reliable and durable products.

Ensuring Consistent Melt Flow

Consistent melt flow is vital for maintaining uniformity in polymer production. The Melt Flow Index (MFI) measures the flow rate of a polymer under specific conditions, directly impacting processing speed and product quality. Monitoring MFI ensures uniformity, as different manufacturing processes, such as extrusion, require specific MFI values for optimal material flow and quality.

The relationship between MFI and molecular weight is crucial; lower MFI values typically correspond to higher molecular weight, enhancing mechanical properties. While higher MFI materials flow more easily, facilitating faster production, they may sacrifice some mechanical strength. Balancing these factors is key to achieving high-quality extruded products.

Monitoring and Maintenance

Regular maintenance schedules are vital to enhance the lifespan and efficiency of extrusion machinery. Advanced monitoring technologies can help identify equipment issues before they affect production, ensuring smooth and uninterrupted operation. Regular inspections identify wear and tear on critical components, helping to prevent unexpected failures.

Maintaining comprehensive maintenance records aids in troubleshooting and scheduling preventive maintenance tasks. These practices extend the life of the equipment and contribute to consistent, high-quality production.

Industry Applications of Plastic Extrusion

Plastic extrusion is widely utilized across industries such as automotive, medical, packaging, and construction. This versatile manufacturing process plays a crucial role in producing essential components, highlighting its importance and widespread application in plastic processing.

The following sections will explore specific industry applications, demonstrating how plastic extrusion meets diverse manufacturing needs and contributes to the development of high-quality products.

Automotive Industry

Plastic extrusion is instrumental in the automotive industry, creating components like weather seals, gaskets, and tubing for fluid systems. Extruded tubing is essential for the effective transfer of fluids, contributing to the overall performance and reliability of automotive systems.

Plastic extrusion in automotive parts provides lightweight solutions that improve fuel efficiency and reduce production costs. This makes it a vital manufacturing process in the automotive sector, enhancing vehicle functionality and performance.

Medical Devices

Plastic extrusion is vital for producing medical tubes and catheters, ensuring compliance with regulatory standards through the use of medical-grade plastics.

Extrusion technology is essential in the medical field for crafting items such as catheters and complex medical tubing compliant with regulatory standards. Medical-grade plastics ensure these products meet the stringent requirements necessary for medical applications.

Packaging Solutions

Plastic extrusion plays a crucial role in manufacturing various packaging materials, including films, wraps, and containers. Polyethylene terephthalate glycol (PETG) is frequently utilized in plastic extrusion due to its excellent clarity and durability. Polycarbonate is favored for its strength and impact resistance, making it suitable for applications like safety equipment and automotive components.

Acrylonitrile Butadiene Styrene (ABS) is known for its ease of processing and balance of strength and flexibility. Combining these materials in extrusion enhances the quality and effectiveness of packaging solutions, meeting diverse industry needs.

Cost Considerations for Extruder Machines

The cost of plastic extruders varies significantly based on their size, complexity, and additional functionalities. Higher capacity extruders usually entail increased production costs due to more advanced engineering and power requirements. The material handling capability of an extruder can also affect its price, especially when dealing with specialized or high-performance plastics.

Implementing energy-efficient practices in the extrusion process can lower operational costs and reduce greenhouse gas emissions associated with plastic production. Modern plastic extruders achieve significant energy savings by utilizing features like variable-speed drives and high-efficiency motors. Investing in advanced extrusion technology can lead to substantial long-term savings by minimizing waste and optimizing production processes.

Initial Investment vs. Long-term Savings

Higher capacity extruders demand more sophisticated engineering and thus cost more than their lower-capacity counterparts. However, the initial investment can be offset by long-term savings through energy-efficient practices and reduced operational costs. Implementing insulation jackets on extruders reduces energy consumption by preventing temperature fluctuations.

Energy efficiency in plastic extrusion processes can be improved by optimizing the speed of the extruder to meet design specifications. These practices reduce operational costs and contribute to a more sustainable manufacturing process.

Financing and Leasing Options

Businesses often explore financing and leasing options to mitigate the upfront costs associated with purchasing extrusion machinery. Leasing extrusion machinery alleviates upfront costs, allowing businesses to invest in equipment without large initial capital outlay. Flexible financing arrangements allow companies to manage cash flow effectively while acquiring new extrusion equipment.

Many suppliers offer financing plans to help businesses manage the upfront costs of acquiring extrusion equipment. These options provide the flexibility needed to invest in advanced extrusion technology without compromising financial stability.

Environmental Impact and Sustainability

Investing in efficient plastic extruders can lead to substantial long-term savings by minimizing waste and optimizing production processes. Efficient production in plastic extrusion leads to notable long-term savings through reduced waste and better material utilization. Advanced extrusion technology contributes to sustainability by significantly reducing production waste over time.

Plastic extrusion reduces environmental waste by transforming discarded materials into reusable products through recycling technologies. This enhances resource efficiency and contributes to a more sustainable manufacturing process.

Recycling Extruders

Recycling extruders are specifically designed to process scrap materials, thereby minimizing waste and enhancing resource efficiency. These machines convert discarded plastic into reusable pellets, which can be reintroduced into the production cycle.

By using recycling extruders, manufacturers reduce their environmental footprint while lowering material costs. This practice supports a circular economy, where materials are continuously reused and recycled, contributing to sustainable manufacturing.

Energy-efficient Practices

Modern plastic extrusion processes focus on energy conservation by optimizing production methods and minimizing energy waste. Integrating renewable energy sources into plastic extrusion operations is becoming crucial for reducing reliance on fossil fuels.

Energy-efficient practices, such as using high-efficiency motors and variable-speed drives, significantly reduce operational costs. These cost-effective practices enhance sustainability and improve the overall efficiency of the extrusion process.

Contacting Suppliers and Manufacturers

When choosing a supplier for plastic extrusion machines, consider their experience, customer support, and customization capabilities. Evaluating a supplier’s capabilities ensures they can meet specific production needs.

Request detailed quotes and proposals from potential suppliers to facilitate comparisons and enable informed purchase decisions. Transparency in pricing and contract terms prevents unexpected costs during the supplier partnership.

Evaluating Supplier Reliability

Evaluating a supplier’s reliability involves assessing their experience, support, and customization capabilities. A reliable supplier demonstrates transparency in pricing and contract terms, helping to prevent unexpected costs during the partnership.

A successful partnership requires ensuring that a supplier can meet specific production needs. This includes evaluating their ability to provide customized solutions and maintain consistent quality delivery standards.

Requesting Quotes and Proposals

Understanding cost considerations when evaluating extruder machines is crucial for informed purchasing decisions. Comparing the initial investment against long-term savings helps businesses understand the total cost of ownership when selecting extruder solutions.

Reaching out to reputable suppliers and manufacturers is essential for obtaining accurate quotes and proposals that meet specific needs. Evaluating a supplier’s reliability based on their experience, support, and access to customization capabilities ensures satisfactory quotes and proposals. If you need further assistance, please feel free to contact us.

Summary

Choosing the right plastic extrusion machine is crucial for optimizing your manufacturing process and achieving high-quality results. Understanding the various types of extruders, their components, and the extrusion process can help you make informed decisions that enhance efficiency and performance.

From single-screw to twin-screw extruders, each type offers unique advantages suited for different applications. Quality assurance, customization, and sustainability practices further contribute to the success of plastic extrusion in various industries. By investing in advanced extrusion technology and exploring financing options, manufacturers can achieve long-term savings and sustainable production.