Extruded plastic shapes are vital in industries like construction and automotive. They are made by melting plastic and forming it through a die. This guide will explain the extrusion process, key materials, and their applications.

- Plastic extrusion is an efficient manufacturing process that transforms thermoplastic materials into custom shapes, crucial for diverse industries.

- Material selection is vital in extrusion, with common materials including polyethylene, PVC, and ABS, each offering unique properties for various applications.

- Custom extruded plastic shapes enhance production efficiency, reduce costs, and support sustainability through minimal waste and the utilization of recycled materials.

Understanding Extruded Plastic Shapes

Plastic extrusion is a marvel of modern manufacturing. It involves melting thermoplastic material and forcing it through a die under pressure to produce continuous profiles like pipes, tubes, and sheets. This process transforms raw plastic pellets into functional and versatile products, including molten plastic, catering to diverse industrial demands.

The historical significance of plastic extrusion cannot be overstated. For over a century, this process has evolved, showcasing its role in high-volume manufacturing. From the early days of rudimentary machines to today’s sophisticated plastic extruders, the journey has been marked by continuous innovation. Modern plastic extruders handle diverse materials and applications, making them indispensable in the plastics industry.

Plastic extrusion stands out for its efficiency and accuracy, enabling the creation of complex shapes with consistent quality, a challenge for other manufacturing methods. Whether it’s for producing standard products like pipes and profiles or custom plastic shapes, the extrusion process offers cost-effectiveness and customization possibilities, particularly when utilizing an extrusion line.

Key Materials for Extruded Plastic Shapes

Material selection in plastic extrusion is crucial to the final product’s performance and application. Common extruded plastic materials include:

- Polyethylene

- Polypropylene

- Polyvinyl chloride (PVC)

- Polystyrene

- Acrylonitrile butadiene styrene (ABS) Each of these materials has unique properties that make them suitable for different uses.

Polyethylene is a versatile thermoplastic used in products from bags to pipes. Its flexibility and durability make it a popular choice in industries requiring robust yet lightweight materials. On the other hand, polypropylene is frequently employed in packaging and automotive components due to its excellent chemical resistance and mechanical properties.

PVC is another widely used plastic material, known for its rigidity and resistance to environmental degradation. It’s commonly used to make window frames and electrical insulation. Polystyrene, meanwhile, is used for signage and packaging materials, offering a balance of strength and affordability.

These materials can be customized for specific applications, ensuring that the final product of extruded manufactured products meets precise performance criteria.

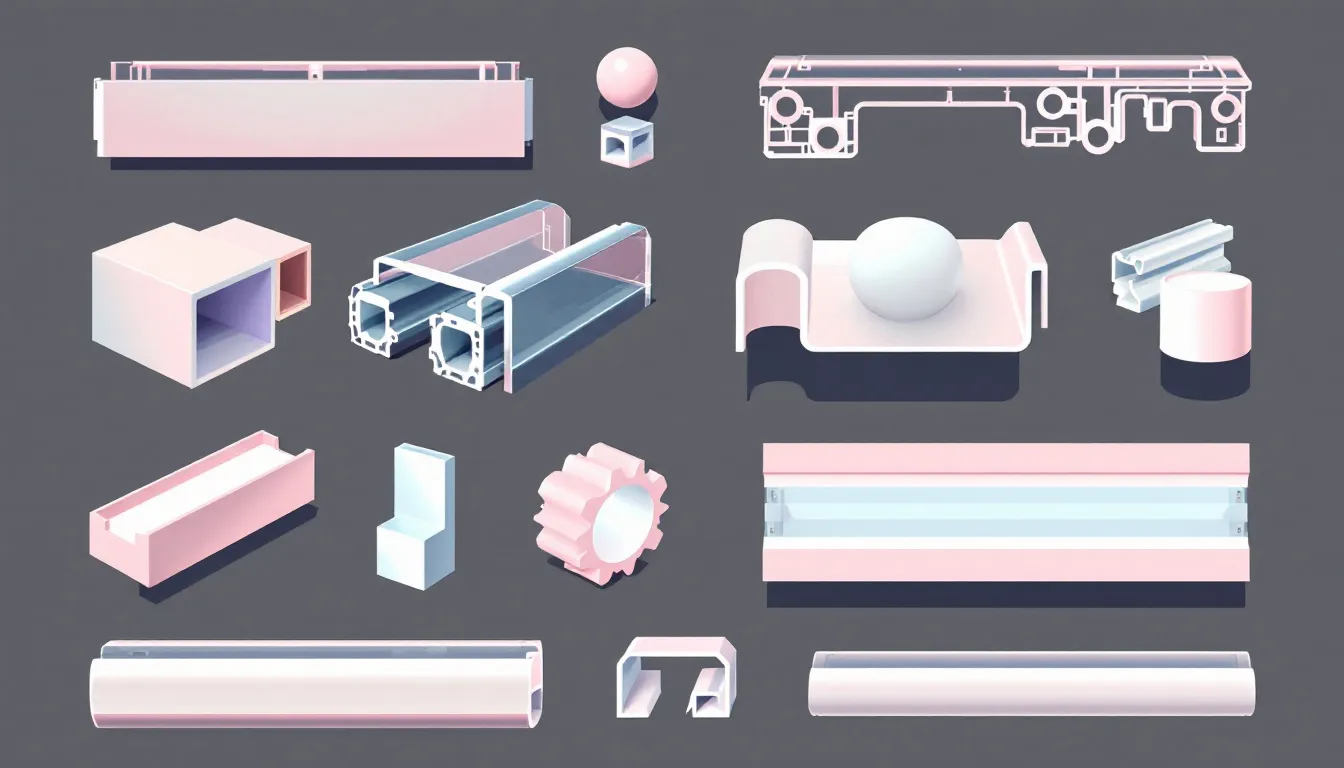

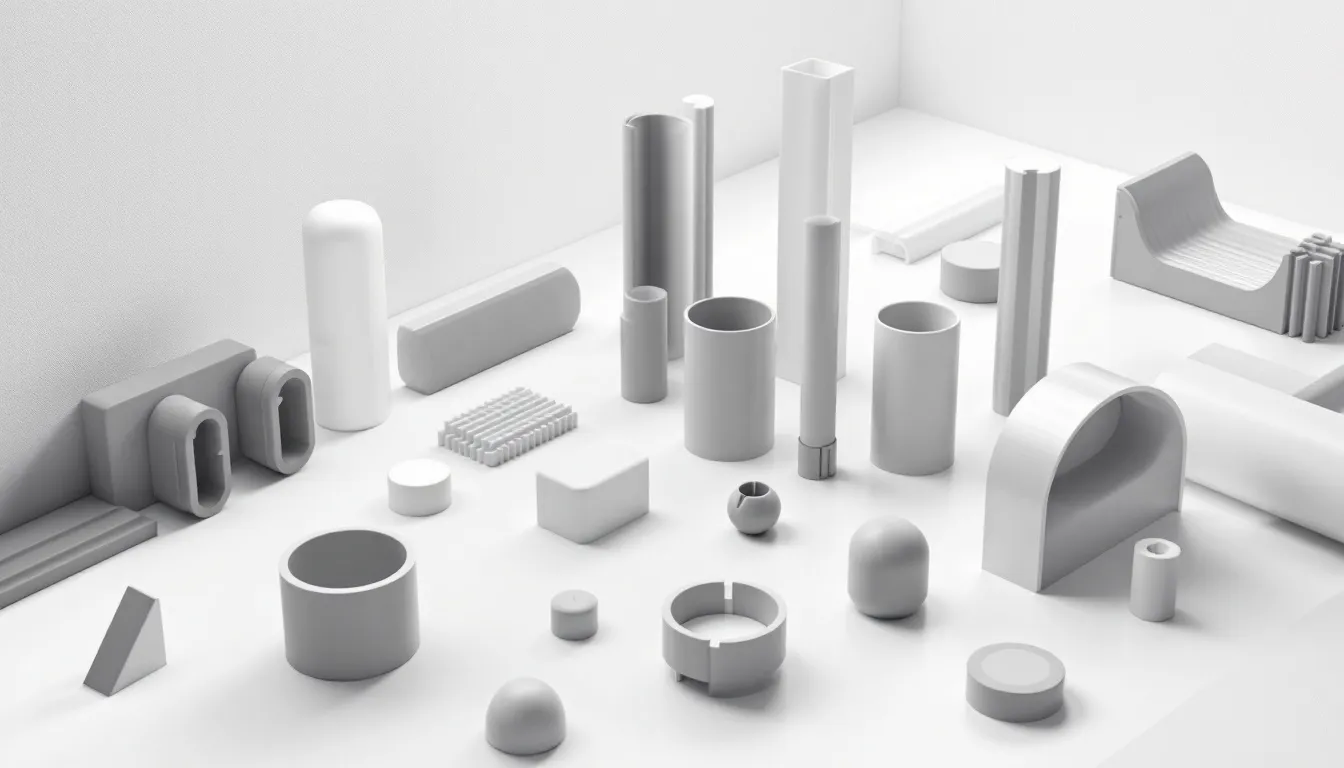

Types of Extruded Plastic Shapes

The versatility of plastic extrusion is evident in the variety of shapes it can produce. From simple pipes and tubes to complex custom profiles, the possibilities are vast. Tubing extrusion, for example, allows for the production of hollow items by utilizing a mandrel within the die. This method is particularly useful for creating products like medical tubing and electrical conduits.

Tailored extruded plastic profiles are used in applications such as:

- Window frames

- Gaskets

- Structural components These are crucial in industries demanding precision and durability. Additionally, plastic sheets and films are produced through extrusion processes, offering a range of sheet thickness and properties for different uses.

Vacuum calibration is often employed to cool and size the extruded plastic thickness immediately after it exits the die, ensuring accurate dimensions and high quality with the use of cooling rolls.

Creating custom shapes through extrusion allows manufacturers to address specific challenges and requirements, making this process essential in many sectors. Whether it’s for standard products or bespoke designs, plastic extrusion provides a reliable solution.

Custom Plastic Extrusion Process

The custom plastic extrusion process is a method of high volume manufacturing process. It involves melting raw plastic and shaping it into continuous profiles. The process includes the following steps:

- Selecting materials that are then fed into a plastic extruder.

- The extruder melts the plastic pellets, creating a polymer melt.

- The polymer melt is forced into a die to shape.

- The shaped plastic hardens as it cools.

Different methods are employed to create custom plastic shapes, including:

- Blow-film extrusion: produces plastic film for packaging.

- Plastic sheet film extrusion: creates large sheets for industrial applications.

- Over-jacketing extrusion.

- Tubing.

Each method offers unique advantages depending on the co desired form and application.

Adjusting parameters like temperature and pressure in plastic extrusion optimizes product properties. This level of control ensures that the final products meet specific performance criteria, making custom plastic extrusion a versatile and efficient manufacturing process.

Twin Screw Extruders vs. Single Screw Extruders

When it comes to plastic extruders, two or more extruders dominate the field: twin screw extruders and single screw extruders. Each type has its own set of advantages and is suited to different applications. The choice between them often depends on production speed, mixing capability, and operational flexibility.

Single screw extruders are generally simpler and less expensive, making them suitable for straightforward extrusion tasks. However, they have slower speeds and limited mixing capabilities, which can be a drawback for more complex applications involving a single extrusion head.

In contrast, twin screw extruders excel in mixing, venting, and processing materials with poor thermal stability. They feature two parallel screws that enhance stability, improve mixing, and allow for increased speed. Twin screw extruders are often preferred for more demanding tasks, such as compounding and reactive extrusion.

Twin screw extruders offer superior performance because:

- They can handle a broader range of materials.

- They provide better extrusion stability.

- They are suitable for producing complex plastic shapes.

- They can handle materials with different viscous plastics.

Benefits of Custom Extruded Plastic Shapes

Custom plastic extrusion offers numerous benefits that make it an attractive option for manufacturers. One of the primary advantages is cost efficiency. Once the initial die is made, the process allows for continuous manufacturing of large quantities, significantly reducing production costs.

The versatility of plastic extrusion is another major benefit. The process can produce complex shapes with high precision, often challenging for other manufacturing methods. Additionally, custom plastic extrusion enables the production of unique shapes with accurate tolerances, ensuring that the final products meet specific requirements.

Involving the extrusion partner early in design and material selection enhances time and cost efficiency. Collaboration with the extrusion partner helps manufacturers optimize production processes and achieve superior results through co extrusion.

Applications of Extruded Plastic Shapes

Extruded plastic shapes find applications in a wide range of industries due to their efficiency and cost-effectiveness. In construction, extruded plastic components for windows and doors:

- Enhance energy efficiency

- Ease installation

- Are lightweight

- Are durable These qualities make them ideal for modern construction projects.

In the automotive industry, extruded plastics are used for weather seals, gaskets, and interior trim components. These products need to withstand harsh environmental conditions, chemicals, and UV exposure, making plastic extrusion a suitable manufacturing process.

The appliance industry also relies on extruded plastics for components like gaskets and seals, which help improve energy efficiency and maintain production volume consistency.

The renewable energy sector benefits from extruded plastic components in solar panels and other systems. These components enhance durability and environmental resistance, contributing to the overall efficiency of renewable energy projects. Moreover, using lightweight extruded plastic parts can reduce transportation energy consumption and lower carbon emissions.

Quality Assurance in Plastic Extrusion

Quality assurance is a crucial aspect of plastic extrusion, ensuring that the final products meet the required standards. Bausano, for example, ensures maximum quality at the technical-functional level during their plastic extrusion process. This involves using high-quality raw materials and advanced machinery to produce reliable plastic extrusions.

Various finishing processes, such as cutting and drilling, can be applied to custom extrusions to enhance their usability. These additional steps help ensure that the final processed products are not only precise but also ready for further processing in their intended applications.

Partnering with a manufacturer that prioritizes quality assurance can significantly impact the performance and durability of plastic extrusions. By choosing a reliable partner, manufacturers can trust that their products will manufacture the highest standards of quality and functionality.

Energy Efficiency in Plastic Extrusion

The plastic extrusion process is inherently energy-efficient and environmentally friendly. Its continuous nature results in minimal waste during production, supporting sustainability initiatives in manufacturing. The process allows using recycled plastics, further minimizing environmental impact.

Strategies to enhance sustainability in plastic extrusion include limiting waste, reducing energy consumption, and using sustainable materials. These efforts are crucial for the plastics industry, which faces significant challenges in minimizing its environmental footprint.

By adopting energy-efficient practices and using recycled materials, manufacturers can contribute to a more sustainable future. Plastic extrusion not only provides cost-effective solutions but also supports environmental responsibility.

Expert Tips for Choosing an Extrusion Partner

Choosing the right extrusion partner is essential for ensuring successful production outcomes. Evaluating the operational capabilities of a potential partner, including machinery, production capacity, and engineering expertise to meet specific requirements, is crucial.

Reputation is another key factor. A partner with a strong reputation ensures reliability and quality in producing extruded plastic profiles. Additionally, the use of high-quality raw materials significantly impacts the durability and performance of the final products.

Clear communication on expectations and challenges during the production process is vital for successful collaboration. Evaluating a partner’s tooling and manufacturing methods can help determine their capacity to produce complex designs and finishes. Ensuring that they have a dedicated customer service team is also important for maintaining effective communication and support throughout the project, especially with the advancements in technology.

How to extrude the plastic products you want

The versatility and efficiency of custom extruded plastic shapes make them indispensable in various industries. From the choice of materials to the intricacies of the extrusion process, each step is designed to produce high-quality, customized products that meet specific needs. Understanding the benefits and applications of plastic extrusion can help manufacturers make informed decisions and optimize their production processes.

Choosing the right extrusion partner is crucial for achieving the best results. By focusing on quality, reputation, and clear communication, manufacturers can ensure that their extruded plastic products meet the highest standards. The journey of plastic extrusion is one of innovation, precision, and sustainability, offering endless possibilities for modern industry.